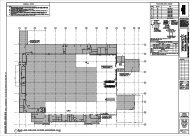

PROJECT MANUAL Specifications Seafood Removal Walmart Store No 1186 Liberty TX

Specs - Home

Specs - Home

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

E. Continue burnishing operations until the specified gloss is attained. Achieve specified gloss no later than two<br />

weeks prior to Grand Opening and maintain specified gloss until Grand Opening.<br />

F. Provide final burnishing prior to Grand Opening as required to eliminate damage from subsequent work.<br />

3.5 FINISH REQUIREMENTS<br />

[St, SC, WNM: Use.<br />

A. Gloss: Final surface gloss shall be a Specified Overall Gloss Value (SOGV) of not less than 40 and Minimum Local<br />

Gloss Value (MLGV) of 30 as measured using a Horiba IG-320 Gloss Checker.]<br />

B. Slip Resistance: Measured static coefficient of friction (SCOF) shall be not less than 0.50 at time of Re-Grand<br />

Opening as measured using an American Slip meter ASM 825 Digital Meter, Regan Scientific Instruments Bot-<br />

3000 Tribometer, or approved equivalent.<br />

C. Provide final burnishing prior to Re-Grand Opening to eliminate any scratches resulting from construction operations.<br />

3.6 FLOOR PROTECTION<br />

A. Protect areas to receive concrete slab surface enhancement at all times during construction to prevent oils, dirt,<br />

metal, excessive water, paint and other potentially damaging materials from affecting the finished concrete surface.<br />

Protective measures listed below shall begin immediately after completion of burnishing.<br />

1. Communicate to <strong>Store</strong>/Club Manager and all subcontractors, vendors, and trades importance of maintaining<br />

slab protection at all times.<br />

2. Protect slab surface from moisture for 72 hours to prevent re-emulsification of surface treatment prior to<br />

cure. Verify that all wood pallets are dry prior to replacing.<br />

3. Each day, inspect all equipment used over completed slab surface, to insure:<br />

a. Equipment is without leaking hydraulic lines and is diapered to avoid staining. Remove all equipment<br />

with hydraulic fluid leaks from store site.<br />

b. <strong>No</strong> tire embedments (rocks, nails, screws, etc.) that will scratch or pit slab surface.<br />

4. Prevent contact with acids and acidic detergents.<br />

5. Use breathable surface protective materials for high traffic areas.<br />

a. EZ-Cover, by McTech Group, (866) 913-8363.<br />

b. Ram Board, by Ram Board, (818) 848-0400.<br />

6. Use breathable drop cloths during all painting. Immediately wipe clean spilled paint.<br />

3.7 PRODUCT DISPOSAL<br />

A. Upon completion of densifier and protective treatment, dispose of excess materials as required by local agency<br />

having jurisdiction.<br />

B. Certified applicator shall remove densifier and protective treatment product containers from job site immediately<br />

upon completion of treatment.<br />

3.8 QUALITY ASSURANCE TESTING<br />

A. Testing will be performed by the Wal-Mart Construction Testing Laboratory (CTL) at no expense to the Contractor.<br />

A test report of all measurements and a plan and table of the measurements taken shall be prepared by the<br />

CTL for submittal. General Contractor shall notify CTL when slab is ready for testing.<br />

03931-7<br />

<strong>Walmart</strong> #<strong>1186</strong> – <strong>Liberty</strong>, <strong>TX</strong> 04/20/11<br />

CMA/10118.034