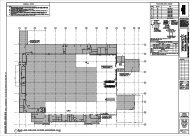

PROJECT MANUAL Specifications Seafood Removal Walmart Store No 1186 Liberty TX

Specs - Home

Specs - Home

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

e. Slab Burnishing Contractor.<br />

1) Project Manager.<br />

2) Foreman present during all preparation and installation Work.<br />

f. Joint Filler Replacement and Slab Repair Subcontractor (if separate)<br />

g. <strong>Walmart</strong> Construction Testing Laboratory.<br />

h. Manufacturers’ representatives for all specified products specified in this section.<br />

5. Convene pre-installation meeting only when all required attendees are present.<br />

6. Review the following:<br />

a. Expectations of finished work specified.<br />

b. Scheduling and phasing of work.<br />

c. Environmental requirements (store working conditions).<br />

d. Existing joint filler replacement.<br />

e. Repair of existing slab defects.<br />

f. Burnishing procedures, including application of liquid densifier system.<br />

g. Field quality control requirements.<br />

h. Slab protection after completion of work.<br />

7. Record and distribute pre-installation meeting minutes to all parties in attendance within 2 days of the<br />

meeting via e-mail in .pdf format. Completed pre-installation meeting agenda is acceptable.<br />

8. Changes to the Contract Documents from recommendations or discussions at the pre-installation meeting<br />

shall be approved in writing by the <strong>Walmart</strong> Construction Manager prior to implementation. <strong>Walmart</strong><br />

Concrete Consultant is NOT authorized to change any specified requirement or to approve execution of any<br />

portion of the Work.<br />

1.6 DELIVERY, STORAGE, AND HANDLING<br />

A. Deliver materials to site in original, factory sealed, unopened, new containers (drums) bearing manufacturer’s<br />

name and label intact and legible, with the following information:<br />

1. Name or title of material.<br />

2. Manufacturer’s standard container (drum) numbers.<br />

3. Application instructions.<br />

B. Storage:<br />

1. <strong>Store</strong> materials in protected and well-ventilated area at temperatures between 40 and 90 degrees F unless<br />

otherwise required by manufacturer.<br />

2. Keep containers sealed until ready for use.<br />

3. Do not use materials beyond manufacturer’s shelf life limits.<br />

C. Handling: Protect materials during handling and application to prevent damage or contamination.<br />

1. Dispense penetrating liquid densifier only from factory sealed and numbered containers (drums).<br />

2. Maintain record of container (drum) numbers received and used during floor treatment.<br />

D. A technically qualified densifier manufacturer’s field representative shall be on site during the initial application<br />

and for periodic observations during remainder of Work.<br />

E. Ensure correct amounts of densifier and protective treatment are onsite and in factory numbered and sealed drums<br />

prior to commencement of Work.<br />

PART 2 - PRODUCTS<br />

2.1 MANUFACTURERS<br />

A. Subject to compliance with project requirements, provide equipment and products as manufactured by the following<br />

to the extent specified.<br />

1. 3M (888) 364-3577, www.3m.com<br />

03367-4<br />

<strong>Walmart</strong> #<strong>1186</strong> – <strong>Liberty</strong>, <strong>TX</strong> 04/2<br />

CMA/10118.034