Datascope - Mindray

Datascope - Mindray

Datascope - Mindray

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

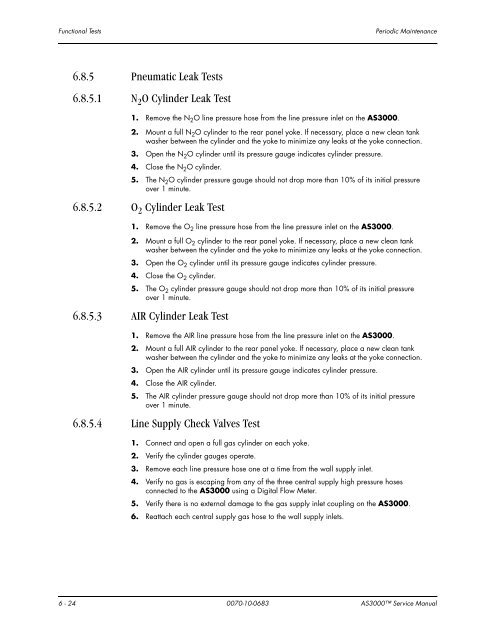

Functional Tests Periodic Maintenance<br />

6.8.5 Pneumatic Leak Tests<br />

6.8.5.1 N 2 O Cylinder Leak Test<br />

1. Remove the N 2 O line pressure hose from the line pressure inlet on the AS3000.<br />

2. Mount a full N2O cylinder to the rear panel yoke. If necessary, place a new clean tank<br />

washer between the cylinder and the yoke to minimize any leaks at the yoke connection.<br />

3. Open the N2O cylinder until its pressure gauge indicates cylinder pressure.<br />

4. Close the N2O cylinder.<br />

5. The N2O cylinder pressure gauge should not drop more than 10% of its initial pressure<br />

over 1 minute.<br />

6.8.5.2 O 2 Cylinder Leak Test<br />

1. Remove the O 2 line pressure hose from the line pressure inlet on the AS3000.<br />

2. Mount a full O2 cylinder to the rear panel yoke. If necessary, place a new clean tank<br />

washer between the cylinder and the yoke to minimize any leaks at the yoke connection.<br />

3. Open the O2 cylinder until its pressure gauge indicates cylinder pressure.<br />

4. Close the O2 cylinder.<br />

5. The O2 cylinder pressure gauge should not drop more than 10% of its initial pressure<br />

over 1 minute.<br />

6.8.5.3 AIR Cylinder Leak Test<br />

1. Remove the AIR line pressure hose from the line pressure inlet on the AS3000.<br />

2. Mount a full AIR cylinder to the rear panel yoke. If necessary, place a new clean tank<br />

washer between the cylinder and the yoke to minimize any leaks at the yoke connection.<br />

3. Open the AIR cylinder until its pressure gauge indicates cylinder pressure.<br />

4. Close the AIR cylinder.<br />

5. The AIR cylinder pressure gauge should not drop more than 10% of its initial pressure<br />

over 1 minute.<br />

6.8.5.4 Line Supply Check Valves Test<br />

1. Connect and open a full gas cylinder on each yoke.<br />

2. Verify the cylinder gauges operate.<br />

3. Remove each line pressure hose one at a time from the wall supply inlet.<br />

4. Verify no gas is escaping from any of the three central supply high pressure hoses<br />

connected to the AS3000 using a Digital Flow Meter.<br />

5. Verify there is no external damage to the gas supply inlet coupling on the AS3000.<br />

6. Reattach each central supply gas hose to the wall supply inlets.<br />

6 - 24 0070-10-0683 AS3000 Service Manual