Datascope - Mindray

Datascope - Mindray

Datascope - Mindray

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

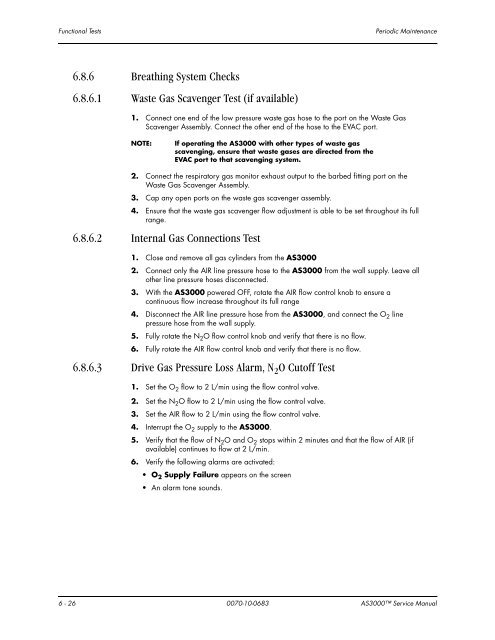

Functional Tests Periodic Maintenance<br />

6.8.6 Breathing System Checks<br />

6.8.6.1 Waste Gas Scavenger Test (if available)<br />

1. Connect one end of the low pressure waste gas hose to the port on the Waste Gas<br />

Scavenger Assembly. Connect the other end of the hose to the EVAC port.<br />

NOTE: If operating the AS3000 with other types of waste gas<br />

scavenging, ensure that waste gases are directed from the<br />

EVAC port to that scavenging system.<br />

2. Connect the respiratory gas monitor exhaust output to the barbed fitting port on the<br />

Waste Gas Scavenger Assembly.<br />

3. Cap any open ports on the waste gas scavenger assembly.<br />

4. Ensure that the waste gas scavenger flow adjustment is able to be set throughout its full<br />

range.<br />

6.8.6.2 Internal Gas Connections Test<br />

1. Close and remove all gas cylinders from the AS3000<br />

2. Connect only the AIR line pressure hose to the AS3000 from the wall supply. Leave all<br />

other line pressure hoses disconnected.<br />

3. With the AS3000 powered OFF, rotate the AIR flow control knob to ensure a<br />

continuous flow increase throughout its full range<br />

4. Disconnect the AIR line pressure hose from the AS3000, and connect the O 2 line<br />

pressure hose from the wall supply.<br />

5. Fully rotate the N 2 O flow control knob and verify that there is no flow.<br />

6. Fully rotate the AIR flow control knob and verify that there is no flow.<br />

6.8.6.3 Drive Gas Pressure Loss Alarm, N 2O Cutoff Test<br />

1. Set the O 2 flow to 2 L/min using the flow control valve.<br />

2. Set the N 2O flow to 2 L/min using the flow control valve.<br />

3. Set the AIR flow to 2 L/min using the flow control valve.<br />

4. Interrupt the O 2 supply to the AS3000.<br />

5. Verify that the flow of N 2O and O 2 stops within 2 minutes and that the flow of AIR (if<br />

available) continues to flow at 2 L/min.<br />

6. Verify the following alarms are activated:<br />

O 2 Supply Failure appears on the screen<br />

An alarm tone sounds.<br />

6 - 26 0070-10-0683 AS3000 Service Manual