Datascope - Mindray

Datascope - Mindray

Datascope - Mindray

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

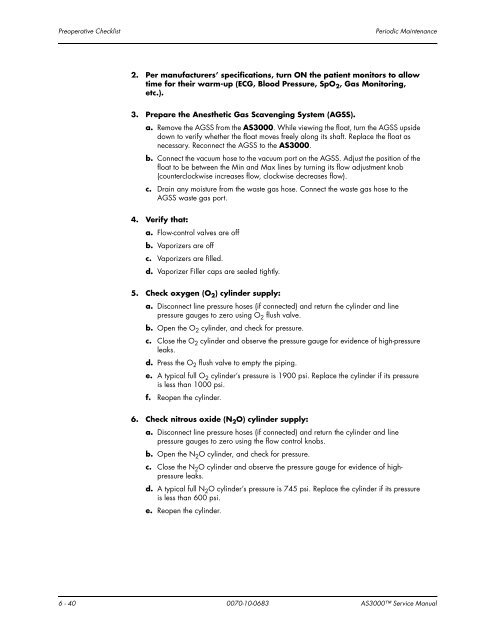

Preoperative Checklist Periodic Maintenance<br />

2. Per manufacturers’ specifications, turn ON the patient monitors to allow<br />

time for their warm-up (ECG, Blood Pressure, SpO 2 , Gas Monitoring,<br />

etc.).<br />

3. Prepare the Anesthetic Gas Scavenging System (AGSS).<br />

a. Remove the AGSS from the AS3000. While viewing the float, turn the AGSS upside<br />

down to verify whether the float moves freely along its shaft. Replace the float as<br />

necessary. Reconnect the AGSS to the AS3000.<br />

b. Connect the vacuum hose to the vacuum port on the AGSS. Adjust the position of the<br />

float to be between the Min and Max lines by turning its flow adjustment knob<br />

(counterclockwise increases flow, clockwise decreases flow).<br />

c. Drain any moisture from the waste gas hose. Connect the waste gas hose to the<br />

AGSS waste gas port.<br />

4. Verify that:<br />

a. Flow-control valves are off<br />

b. Vaporizers are off<br />

c. Vaporizers are filled.<br />

d. Vaporizer Filler caps are sealed tightly.<br />

5. Check oxygen (O 2) cylinder supply:<br />

a. Disconnect line pressure hoses (if connected) and return the cylinder and line<br />

pressure gauges to zero using O 2 flush valve.<br />

b. Open the O 2 cylinder, and check for pressure.<br />

c. Close the O 2 cylinder and observe the pressure gauge for evidence of high-pressure<br />

leaks.<br />

d. Press the O 2 flush valve to empty the piping.<br />

e. A typical full O 2 cylinder’s pressure is 1900 psi. Replace the cylinder if its pressure<br />

is less than 1000 psi.<br />

f. Reopen the cylinder.<br />

6. Check nitrous oxide (N 2 O) cylinder supply:<br />

a. Disconnect line pressure hoses (if connected) and return the cylinder and line<br />

pressure gauges to zero using the flow control knobs.<br />

b. Open the N 2O cylinder, and check for pressure.<br />

c. Close the N 2 O cylinder and observe the pressure gauge for evidence of highpressure<br />

leaks.<br />

d. A typical full N 2 O cylinder’s pressure is 745 psi. Replace the cylinder if its pressure<br />

is less than 600 psi.<br />

e. Reopen the cylinder.<br />

6 - 40 0070-10-0683 AS3000 Service Manual