Datascope - Mindray

Datascope - Mindray

Datascope - Mindray

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

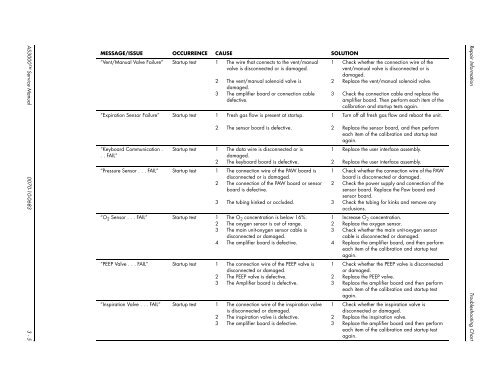

AS3000 Service Manual 0070-10-0683 3 - 5<br />

MESSAGE/ISSUE OCCURRENCE CAUSE SOLUTION<br />

“Vent/Manual Valve Failure” Startup test 1 The wire that connects to the vent/manual<br />

valve is disconnected or is damaged.<br />

2 The vent/manual solenoid valve is<br />

damaged.<br />

3 The amplifier board or connection cable<br />

defective.<br />

“Expiration Sensor Failure” Startup test 1 Fresh gas flow is present at startup.<br />

“Keyboard Communication .<br />

. . FAIL”<br />

2 The sensor board is defective.<br />

Startup test 1 The data wire is disconnected or is<br />

damaged.<br />

2 The keyboard board is defective.<br />

“Pressure Sensor . . . FAIL” Startup test 1 The connection wire of the PAW board is<br />

disconnected or is damaged.<br />

2 The connection of the PAW board or sensor<br />

board is defective.<br />

3 The tubing kinked or occluded.<br />

“O 2 Sensor . . . FAIL” Startup test 1 The O 2 concentration is below 16%.<br />

2 The oxygen sensor is out of range.<br />

3 The main unit-oxygen sensor cable is<br />

disconnected or damaged.<br />

4 The amplifier board is defective.<br />

“PEEP Valve . . . FAIL” Startup test 1 The connection wire of the PEEP valve is<br />

disconnected or damaged.<br />

2 The PEEP valve is defective.<br />

3 The Amplifier board is defective.<br />

“Inspiration Valve . . . FAIL” Startup test 1 The connection wire of the inspiration valve<br />

is disconnected or damaged.<br />

2 The inspiration valve is defective.<br />

3 The amplifier board is defective.<br />

1 Check whether the connection wire of the<br />

vent/manual valve is disconnected or is<br />

damaged.<br />

2 Replace the vent/manual solenoid valve.<br />

3 Check the connection cable and replace the<br />

amplifier board. Then perform each item of the<br />

calibration and startup tests again.<br />

1 Turn off all fresh gas flow and reboot the unit.<br />

2 Replace the sensor board, and then perform<br />

each item of the calibration and startup test<br />

again.<br />

1 Replace the user interface assembly.<br />

2 Replace the user interface assembly.<br />

1 Check whether the connection wire of the PAW<br />

board is disconnected or damaged.<br />

2 Check the power supply and connection of the<br />

sensor board. Replace the Paw board and<br />

sensor board.<br />

3 Check the tubing for kinks and remove any<br />

occlusions.<br />

1 Increase O2 concentration.<br />

2 Replace the oxygen sensor.<br />

3 Check whether the main unit-oxygen sensor<br />

cable is disconnected or damaged.<br />

4 Replace the amplifier board, and then perform<br />

each item of the calibration and startup test<br />

again.<br />

1 Check whether the PEEP valve is disconnected<br />

or damaged.<br />

2 Replace the PEEP valve.<br />

3 Replace the amplifier board and then perform<br />

each item of the calibration and startup test<br />

again.<br />

1 Check whether the inspiration valve is<br />

disconnected or damaged.<br />

2 Replace the inspiration valve.<br />

3 Replace the amplifier board and then perform<br />

each item of the calibration and startup test<br />

again.<br />

Repair Information Troubleshooting Chart