Datascope - Mindray

Datascope - Mindray

Datascope - Mindray

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

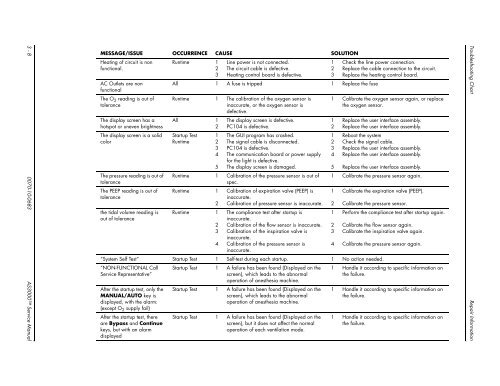

3 - 8 0070-10-0683 AS3000 Service Manual<br />

MESSAGE/ISSUE OCCURRENCE CAUSE SOLUTION<br />

Heating of circuit is non<br />

functional.<br />

AC Outlets are non<br />

functional<br />

The O2 reading is out of<br />

tolerance<br />

The display screen has a<br />

hotspot or uneven brightness<br />

The display screen is a solid<br />

color<br />

The pressure reading is out of<br />

tolerance<br />

The PEEP reading is out of<br />

tolerance<br />

the tidal volume reading is<br />

out of tolerance<br />

Runtime 1 Line power is not connected.<br />

2 The circuit cable is defective.<br />

3 Heating control board is defective.<br />

All 1 A fuse is tripped 1 Replace the fuse<br />

Runtime 1 The calibration of the oxygen sensor is<br />

inaccurate, or the oxygen sensor is<br />

defective.<br />

All 1 The display screen is defective.<br />

2 PC104 is defective.<br />

Startup Test<br />

Runtime<br />

1 The GUI program has crashed.<br />

2 The signal cable is disconnected.<br />

3 PC104 is defective.<br />

4 The communication board or power supply<br />

for the light is defective.<br />

5 The display screen is damaged.<br />

Runtime 1 Calibration of the pressure sensor is out of<br />

spec.<br />

Runtime 1 Calibration of expiration valve (PEEP) is<br />

inaccurate.<br />

2 Calibration of pressure sensor is inaccurate.<br />

Runtime 1 The compliance test after startup is<br />

inaccurate.<br />

2 Calibration of the flow sensor is inaccurate.<br />

3 Calibration of the inspiration valve is<br />

inaccurate.<br />

4 Calibration of the pressure sensor is<br />

inaccurate.<br />

1 Check the line power connection.<br />

2 Replace the cable connection to the circuit.<br />

3 Replace the heating control board.<br />

1 Calibrate the oxygen sensor again, or replace<br />

the oxygen sensor.<br />

1 Replace the user interface assembly.<br />

2 Replace the user interface assembly.<br />

1 Reboot the system<br />

2 Check the signal cable.<br />

3 Replace the user interface assembly.<br />

4 Replace the user interface assembly.<br />

5 Replace the user interface assembly.<br />

1 Calibrate the pressure sensor again.<br />

1 Calibrate the expiration valve (PEEP).<br />

2 Calibrate the pressure sensor.<br />

1 Perform the compliance test after startup again.<br />

2 Calibrate the flow sensor again.<br />

3 Calibrate the inspiration valve again.<br />

4 Calibrate the pressure sensor again.<br />

“System Self Test” Startup Test 1 Self-test during each startup. 1 No action needed.<br />

“NON-FUNCTIONAL Call<br />

Service Representative”<br />

After the startup test, only the<br />

MANUAL/AUTO key is<br />

displayed, with the alarm:<br />

(except O2 supply fail)<br />

After the startup test, there<br />

are Bypass and Continue<br />

keys, but with an alarm<br />

displayed<br />

Startup Test 1 A failure has been found (Displayed on the<br />

screen), which leads to the abnormal<br />

operation of anesthesia machine.<br />

Startup Test 1 A failure has been found (Displayed on the<br />

screen), which leads to the abnormal<br />

operation of anesthesia machine.<br />

Startup Test 1 A failure has been found (Displayed on the<br />

screen), but it does not affect the normal<br />

operation of each ventilation mode.<br />

1 Handle it according to specific information on<br />

the failure.<br />

1 Handle it according to specific information on<br />

the failure.<br />

1 Handle it according to specific information on<br />

the failure.<br />

Troubleshooting Chart Repair Information