- Page 2 and 3:

Volume - 2Technical RequirementsSec

- Page 4 and 5:

GHORASAL 200 MW to 300 MW GAS TURBI

- Page 6:

2. Scope Of Work2.0 Scope of work2.

- Page 9 and 10:

3. Generator switchgeara. Outdoor e

- Page 11 and 12:

Rated frequency: 50 HzRated nominal

- Page 13 and 14:

Lighting impulseWithstand voltage(1

- Page 15 and 16:

h. One (1) Lot Control and instrume

- Page 17 and 18: 2.13 TestsThe Contractor shall be r

- Page 19 and 20: Section 3Power Plant ArrangementGho

- Page 21 and 22: 3.0 Power Plant Arrangement3.1 Gene

- Page 23 and 24: 3.3.2.4 Compressor Wet Washing Syst

- Page 26 and 27: The distillate fuel oil system shal

- Page 28 and 29: 6. Sump tankThe sump tank allows dr

- Page 30 and 31: provide necessary protection for ma

- Page 32 and 33: 4. Generator And Ancillary Equipmen

- Page 34 and 35: 4.1.4 Temperature RiseThe temperatu

- Page 36 and 37: 4.1.12 Accessoriesa. Temperature de

- Page 38 and 39: - Secondary wiring including cable

- Page 40 and 41: 4.3.6 Voltage TransformerThe voltag

- Page 42 and 43: 3) The rated service voltage shall

- Page 44 and 45: Section 5TransformersGhorasal 200 M

- Page 46 and 47: 5. TRANSFORMERS5.1 GENERALThe trans

- Page 48 and 49: . The tank shall be of the welded s

- Page 50 and 51: The wiring shall be connected at th

- Page 52 and 53: 5.3 UNIT AUXILIARY TRANSFORMER5.3.1

- Page 54 and 55: h. Anchor devicei. Oil preservation

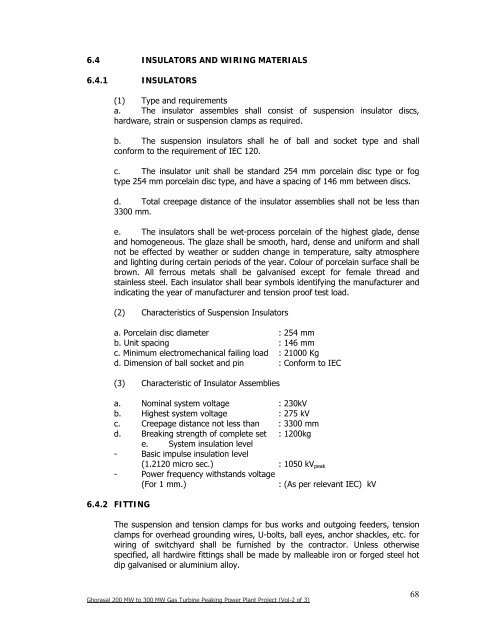

- Page 56 and 57: 6. 230 kV OUTDOOR SWITCHGEAR, EQUIP

- Page 58 and 59: -Power frequency withstand voltage(

- Page 60 and 61: eaker.(6) Dielectric Test Voltagea.

- Page 62 and 63: . Rated insulation level- Lighting

- Page 64 and 65: f. Unless otherwise specified, the

- Page 66 and 67: 6.3.2 DESIGN CRITERIAThe steel stru

- Page 70 and 71: Section 76.6 Kv SwitchgearAndLow Te

- Page 72 and 73: 7. 6.6 kV SWITCHGEAR AND LOW TENSIO

- Page 74 and 75: - Number of circuit :Determined by

- Page 76 and 77: Section 8Control And ProtectionGhor

- Page 78 and 79: 8. CONTROL AND PROTECTION EQUIPMENT

- Page 80 and 81: - Automatic synchronising equipment

- Page 82 and 83: ee. AVR failure xff. Emergency Trip

- Page 84 and 85: can be seen through the window with

- Page 86 and 87: Required no. of 6.6 kV and 415 V vo

- Page 88 and 89: 8.10.3 CONTROL EQUIPMENT(1) Transmi

- Page 90 and 91: The test block shall be of the back

- Page 92 and 93: Section 9Cabling And GroundingGhora

- Page 94 and 95: 9. CABLING AND GROUNDING9.1 GENERAL

- Page 96 and 97: 9.2.4 CONTROL AND INSTRUMENT CABLES

- Page 98 and 99: 9.4 CABLE ERECTIONConcrete lined ca

- Page 100 and 101: Section 10DC Power Supply SystemGho

- Page 102 and 103: 10 DC POWER SUPPLY SYSTEM10.1 BATTE

- Page 104 and 105: float charge as well as boost charg

- Page 106 and 107: Section 11Lighting And Small Power

- Page 108 and 109: 11. LIGHTING AND SMALL POWER SUPPLY

- Page 110 and 111: (ii)Three phase plug socketOutdoor-

- Page 112 and 113: Section 12Fuel Handling FacilitiesG

- Page 114 and 115: 12. FUEL OIL SYSTEM AND HANDLING FA

- Page 116 and 117: from unloading base to the fuel tan

- Page 118 and 119:

13. FIRE PROTECTION FACILITIES13.1

- Page 120 and 121:

System of lock off to (but not exit

- Page 122 and 123:

Section 14Communication FacilitiesG

- Page 124 and 125:

14. COMMUNICATION FACILITIES14.1 GE

- Page 126 and 127:

(2) General CommunicationWhen the o

- Page 128 and 129:

(1) BatteryType of batteryCapacityN

- Page 130 and 131:

15. MAINTENANCE FACILITIESPage15.1

- Page 132 and 133:

15.1.4 RATINGThe rating of the cran

- Page 134 and 135:

The main power supply shall have a

- Page 136 and 137:

Static tests of all automatic seque

- Page 138 and 139:

Section 16Tests And InspectionsGhor

- Page 140 and 141:

16 TESTS AND INSPECTIONS16.1 GENERA

- Page 142 and 143:

subjected to the following tests by

- Page 144 and 145:

c. Stranded Conductors for Overhead

- Page 146 and 147:

days from the receipt of the said n

- Page 148 and 149:

circuit of unit motor control centr

- Page 150 and 151:

Special measures may have to be tak

- Page 152 and 153:

Checks shall be made of the local a

- Page 154 and 155:

Section 17Civil WorksGhorasal 200 M

- Page 156 and 157:

17.9 Sewage Works17.9.1 General17.9

- Page 158 and 159:

17.1.4 SITE LABORATORYThe Contracto

- Page 160 and 161:

where directed by the Board extra s

- Page 162 and 163:

approval regarding the re-measureme

- Page 164 and 165:

igidly in position down to the lowe

- Page 166 and 167:

on piles together with the apparatu

- Page 168 and 169:

than 15 cm in size containing suita

- Page 170 and 171:

aggregates shall be washed prior to

- Page 172 and 173:

17.6.13 FORMWORK AND TIMBERINGFormw

- Page 174 and 175:

he Contractor shall repair at his o

- Page 176 and 177:

Sieve designationPercentage by(Squa

- Page 178 and 179:

(b) Transverse Joints: The transver

- Page 180 and 181:

17.7.2 Gravel SurfacingThe Contract

- Page 182 and 183:

extended with sufficient number of

- Page 184 and 185:

A written record of the drilling in

- Page 186 and 187:

) Control EquipmentThe control equi

- Page 188 and 189:

17.12.2 GatesSliding metal gates of

- Page 190 and 191:

18 Building WORKS18.1 General18.1.1

- Page 192 and 193:

18.1.4 RecordsThe Contractor shall

- Page 194 and 195:

FrameRoofExterior wallPartition wal

- Page 196 and 197:

18.5 Materials And Workmanship18.5.

- Page 198 and 199:

(7) PaintPrior to delivery after sh

- Page 200 and 201:

oof cladding shall be less than 1.1

- Page 202 and 203:

. Wooden doorsPlywood for panelThic

- Page 204 and 205:

The terrazzo is to be trowelled to

- Page 206 and 207:

to suit. Stud shall be formed of ap

- Page 208 and 209:

Section 19Spare PartsGhorasal 200 M

- Page 210 and 211:

19. SPARE PARTS19.1 GENERALThe Cont

- Page 212 and 213:

BACKGROUND INFORMATION:Bangladesh P

- Page 214 and 215:

- Overhauling of all electrical mot

- Page 216 and 217:

3. BASIS OF PRICE3.1 Basis of price

- Page 218 and 219:

the delayed services or such other

- Page 220 and 221:

13. GENERAL CLAUSES CONCERNING TERM

- Page 222 and 223:

17. INSURANCEThe insurance includin

- Page 224:

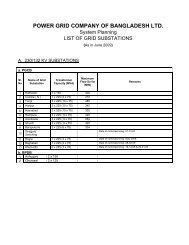

Appendixes20.1 Site Layout20.2 Grid