Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

I tonnage<br />

I<br />

member<br />

:<br />

Crete.<br />

'<br />

I<br />

I tensile<br />

I<br />

I The<br />

,L ment—usually high-tensile strength steel<br />

°, *<br />

^'<br />

I wires— is stretched so as to place the con-<br />

Crete in compression. This enables the cono<br />

' Crete to eliminate or better withstand the<br />

f<br />

stresses to which it is subjected<br />

f<br />

,*'<br />

""^i I WIRE<br />

'"');<br />

*'*!<br />

1<br />

under heavy loads.<br />

REDUCES STEEL TONNAGE<br />

amount of wire used as reinforcement<br />

In prestressed concrete is only a frac-<br />

I tlon — usually about one-fourth — of the<br />

of steel reinforcing bars needed<br />

for a corresponding structure or structural<br />

of conventional reinforced con-<br />

While the unit cost of the steel wire<br />

is higher than that of bars, the amount<br />

and weight used is considerably less, so<br />

I<br />

that in the long run, materials costs are<br />

usually less for prestressed concrete. The<br />

most important features of prestressed concrete<br />

are that it breaks down previous<br />

limitations on the spans and loads for<br />

which a concrete structure can be economically<br />

designed, and that the concrete<br />

is made free from tension and from cracking.<br />

Also, of great importance today, is<br />

the fact that there is<br />

the weight of<br />

steel required.<br />

Prestressed concrete, like<br />

actually a saving in<br />

thin-shell roof<br />

construction, has found its greatest use in<br />

England and on the European continent.<br />

Wartime and postwar materials shortages<br />

made its use practical for rebuilding and<br />

restoration work and for new construction.<br />

While prestressing techniques had<br />

been used in this country in construction<br />

of circular tanks and pipe, it was not until<br />

the start of the Walnut Lane Bridge in<br />

Philadelphia In late 1949 that prestressed<br />

concrete was used for other types of structures.<br />

Since that time, interest has pyramided<br />

among American engineers. More is<br />

being learned about prestressing practices<br />

and procedures, and it is almost certain<br />

that it will find increasingly wide application<br />

in this country in the coming years.<br />

METHODS THOROUGHLY PROVED<br />

Both thin-shell roof construction and<br />

prestressed concrete are thoroughly proved<br />

methods of construction. Both save steel;<br />

both require less concrete than conventional<br />

reinforced concrete: both are eminently<br />

practical for theatre construction.<br />

An excellent example of how steel can<br />

be saved through use of these types of construction<br />

is a hangar at Karachi, Pakistan.<br />

Not unlike a theatre, the hangar required<br />

a large unobstructed ground floor area,<br />

and in addition an unusually wide door<br />

opening for the admission of large planes.<br />

The roof was built of barrel shells of concrete<br />

only two and one-half inches thick,<br />

utilizing much less steel than would normally<br />

have been required. The prestressed<br />

concrete girders over the hangar doors<br />

were called upon to span openings 200 feet<br />

wide, and required 10 tons of steel each.<br />

But if steel girders of the same span and<br />

depth had been used, it was estimated that<br />

they would have weighed as much as 100<br />

tons each ... or fen times as much! Thus<br />

in the two girders alone there was an<br />

estimated saving of ninety per cent in steel.<br />

In addition to these two methods of<br />

construction, there are several general<br />

ways in which steel can be saved, more or<br />

less common sense ideas that will occur to<br />

most architects. They may not .seem<br />

dramatic, but this does not detract from<br />

I heir effectiveness.<br />

A few steel-saving suggestions include:<br />

elimination of wasteful overdesign in walls,<br />

columns, beams and floor slabs: reduction<br />

of roof and floor span lengths where<br />

possible: greater use of arches: use of concrete<br />

masonry for bearing walls as well as<br />

for "back up" and interior partitions: Increasing<br />

the strength of the concrete to<br />

reduce the amount of compressive reinforcement<br />

needed: use of control joints to<br />

reduce wall reinforcement, and the use of<br />

plain concrete wherever possible, such as<br />

in footings and below surface construction<br />

where mass concrete sections may often<br />

be used to eliminate all steel.<br />

GOOD DESIGN CAN SAVE STEEL<br />

Sometimes ways of saving steel are<br />

readily apparent. For example, in World<br />

War 11 the beforementioned methods and<br />

similar procedures were used in the redesign<br />

of five military warehouses from<br />

steel frame to reinforced concrete, and<br />

resulted in a net saving of 67 per cent of<br />

the tonnage required in the all-steel design.<br />

Such large savings as this cannot usually<br />

be hoped for in the construction of the<br />

average theatre, where a goodly amount of<br />

concrete is normally employed. But substantial<br />

savings can be made through good<br />

design and through careful attention to<br />

small as well as large items. No saving,<br />

regardless of how inconsequential it may<br />

seem at the time, should be overlooked.<br />

Nor should an idea be discarded as not<br />

worthy of redesign until every portion of<br />

the theatre has been carefully checked.<br />

The difference between a completed<br />

structure and one never started may lie in<br />

overlooking the obvious or in discounting<br />

as "new fangled" procedures and methods<br />

which have been thoroughly proved.<br />

NPA Building Restrictions<br />

Apply to<br />

Used Materials<br />

Exhibitors who plan to build new theatres<br />

and have been able to secure used<br />

materials must still comply with NPA restrictions.<br />

Steel and copper which may have been<br />

secured from razed buildings must be<br />

counted as a part of the allowable quantities<br />

permitted under NPA Order M4-A,<br />

namely, two tons of carbon steel and 200<br />

pounds of copper.<br />

This recent order removed the cost<br />

ceiling for new theatre construction which<br />

is now limited only by the amount of restricted<br />

materials used.<br />

Brick masonry is one of the most common<br />

constructions used for permanent exterior<br />

walls. It provides enduring and<br />

sturdy structural elements.<br />

A Model For Every Type<br />

and Size of Operation<br />

ELECTRIC<br />

AUTOMATICKET<br />

for top-traffic<br />

installations in<br />

Theatres, Amusement<br />

Parks, Fairs,<br />

Race Tracks<br />

^<br />

"RAPID ACTION"<br />

AUTOMATICKET<br />

A mechanically<br />

driven, rock-bottom-price<br />

ticket<br />

register for smaller<br />

theatres<br />

"TRIGGER ACTION"<br />

AUTOMATICKET<br />

the world's outstanding<br />

performer<br />

among nonelectric<br />

ticket<br />

issuing machines<br />

. . all carrying<br />

all geared fo maximum efficiency<br />

and economy .<br />

GRC's famous Uninterrupted-<br />

Service Guarantee<br />

GENERAL REGISTER CORPORATION<br />

43-01 Twenty-Second Street<br />

Long Island City 1, N. Y.<br />

1018 South Wobash Avenue<br />

Chicago 5, Illinois<br />

6260 Romoine Street<br />

Hollywood 38, Calif.<br />

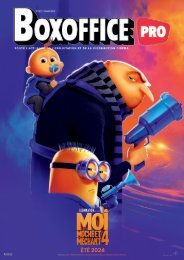

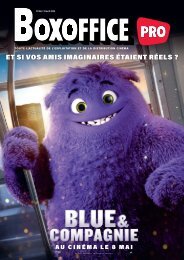

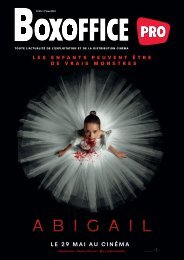

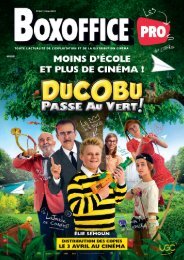

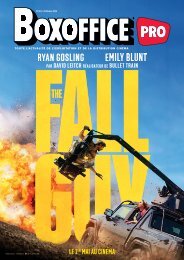

BOXOFFICE 37