- Page 2 and 3:

Gas Turbine Handbook: Principles an

- Page 4 and 5:

Gas Turbine Handbook: Principles an

- Page 6 and 7:

Dedication This book is dedicated t

- Page 8 and 9:

Contents PREFACE ..................

- Page 10 and 11:

Chapter 13—BOROSCOPE INSPECTION .

- Page 12 and 13:

Preface to the Third Edition The ne

- Page 14 and 15:

Acknowledgments I wish to thank the

- Page 16 and 17:

2 Gas Turbine Handbook: Principles

- Page 18 and 19:

4 Gas Turbine Handbook: Principles

- Page 20 and 21:

6 Gas Turbine Handbook: Principles

- Page 22 and 23:

8 Gas Turbine Handbook: Principles

- Page 24 and 25:

10 Gas Turbine Handbook: Principles

- Page 26 and 27:

12 Gas Turbine Handbook: Principles

- Page 28 and 29:

Figure 2-3. Courtesy of United Tech

- Page 30 and 31:

16 Gas Turbine Handbook: Principles

- Page 32 and 33:

18 Gas Turbine Handbook: Principles

- Page 34 and 35:

20 Gas Turbine Handbook: Principles

- Page 36 and 37:

22 Gas Turbine Handbook: Principles

- Page 38 and 39:

24 Gas Turbine Handbook: Principles

- Page 40 and 41:

26 Gas Turbine Handbook: Principles

- Page 42 and 43:

28 Gas Turbine Handbook: Principles

- Page 44 and 45:

30 Gas Turbine Handbook: Principles

- Page 46 and 47:

32 Gas Turbine Handbook: Principles

- Page 48 and 49:

34 Gas Turbine Handbook: Principles

- Page 50 and 51:

36 Gas Turbine Handbook: Principles

- Page 52 and 53:

38 Gas Turbine Handbook: Principles

- Page 54 and 55:

40 Gas Turbine Handbook: Principles

- Page 56 and 57:

42 Gas Turbine Handbook: Principles

- Page 58 and 59:

This page intentionally left blank

- Page 60 and 61:

46 Gas Turbine Handbook: Principles

- Page 62 and 63:

48 Gas Turbine Handbook: Principles

- Page 64 and 65:

50 Gas Turbine Handbook: Principles

- Page 66 and 67:

52 Gas Turbine Handbook: Principles

- Page 68 and 69:

54 Gas Turbine Handbook: Principles

- Page 70 and 71:

56 Gas Turbine Handbook: Principles

- Page 72 and 73:

58 Gas Turbine Handbook: Principles

- Page 74 and 75:

60 Gas Turbine Handbook: Principles

- Page 76 and 77:

62 Gas Turbine Handbook: Principles

- Page 78 and 79:

64 Gas Turbine Handbook: Principles

- Page 80 and 81:

66 Gas Turbine Handbook: Principles

- Page 82 and 83:

68 Gas Turbine Handbook: Principles

- Page 84 and 85:

70 Gas Turbine Handbook: Principles

- Page 86 and 87:

72 Gas Turbine Handbook: Principles

- Page 88 and 89:

74 Gas Turbine Handbook: Principles

- Page 90 and 91:

Figure 5-4. Courtesy of United Tech

- Page 92 and 93:

78 Gas Turbine Handbook: Principles

- Page 94 and 95:

80 Gas Turbine Handbook: Principles

- Page 96 and 97:

82 Gas Turbine Handbook: Principles

- Page 98 and 99:

84 Gas Turbine Handbook: Principles

- Page 100 and 101:

86 Gas Turbine Handbook: Principles

- Page 102 and 103:

88 Gas Turbine Handbook: Principles

- Page 104 and 105:

90 Gas Turbine Handbook: Principles

- Page 106 and 107:

92 Gas Turbine Handbook: Principles

- Page 108 and 109:

94 Gas Turbine Handbook: Principles

- Page 110 and 111:

96 Gas Turbine Handbook: Principles

- Page 112 and 113:

98 Gas Turbine Handbook: Principles

- Page 114 and 115:

100 Gas Turbine Handbook: Principle

- Page 116 and 117:

102 Gas Turbine Handbook: Principle

- Page 118 and 119:

104 Gas Turbine Handbook: Principle

- Page 120 and 121:

106 Gas Turbine Handbook: Principle

- Page 122 and 123:

108 Gas Turbine Handbook: Principle

- Page 124 and 125:

110 Gas Turbine Handbook: Principle

- Page 126 and 127:

112 Gas Turbine Handbook: Principle

- Page 128 and 129:

This page intentionally left blank

- Page 130 and 131:

Chart 8-1 Gas Turbine Environments

- Page 132 and 133:

118 Gas Turbine Handbook: Principle

- Page 134 and 135:

120 Gas Turbine Handbook: Principle

- Page 136 and 137:

122 Gas Turbine Handbook: Principle

- Page 138 and 139:

124 Gas Turbine Handbook: Principle

- Page 140 and 141:

126 Gas Turbine Handbook: Principle

- Page 142 and 143:

128 Gas Turbine Handbook: Principle

- Page 144 and 145:

130 Gas Turbine Handbook: Principle

- Page 146 and 147:

132 Gas Turbine Handbook: Principle

- Page 148 and 149:

134 Gas Turbine Handbook: Principle

- Page 150 and 151:

136 Gas Turbine Handbook: Principle

- Page 152 and 153:

138 Gas Turbine Handbook: Principle

- Page 154 and 155:

140 Gas Turbine Handbook: Principle

- Page 156 and 157:

142 Gas Turbine Handbook: Principle

- Page 158 and 159:

144 Gas Turbine Handbook: Principle

- Page 160 and 161:

146 Gas Turbine Handbook: Principle

- Page 162 and 163:

148 Gas Turbine Handbook: Principle

- Page 164 and 165:

150 Gas Turbine Handbook: Principle

- Page 166 and 167:

152 Gas Turbine Handbook: Principle

- Page 168 and 169:

154 Gas Turbine Handbook: Principle

- Page 170 and 171:

156 Gas Turbine Handbook: Principle

- Page 172 and 173:

158 Gas Turbine Handbook: Principle

- Page 174 and 175:

160 Gas Turbine Handbook: Principle

- Page 176 and 177:

162 Gas Turbine Handbook: Principle

- Page 178 and 179:

164 Gas Turbine Handbook: Principle

- Page 180 and 181:

166 Gas Turbine Handbook: Principle

- Page 182 and 183:

This page intentionally left blank

- Page 184 and 185:

170 Gas Turbine Handbook: Principle

- Page 186 and 187:

172 Gas Turbine Handbook: Principle

- Page 188 and 189:

174 Gas Turbine Handbook: Principle

- Page 190 and 191:

176 Gas Turbine Handbook: Principle

- Page 192 and 193:

178 Gas Turbine Handbook: Principle

- Page 194 and 195:

180 Gas Turbine Handbook: Principle

- Page 196 and 197:

This page intentionally left blank

- Page 198 and 199:

184 Gas Turbine Handbook: Principle

- Page 200 and 201:

186 Gas Turbine Handbook: Principle

- Page 202 and 203: 188 Gas Turbine Handbook: Principle

- Page 204 and 205: 190 Gas Turbine Handbook: Principle

- Page 206 and 207: 192 Gas Turbine Handbook: Principle

- Page 208 and 209: 194 Gas Turbine Handbook: Principle

- Page 210 and 211: 196 Gas Turbine Handbook: Principle

- Page 212 and 213: 198 Gas Turbine Handbook: Principle

- Page 214 and 215: 200 Gas Turbine Handbook: Principle

- Page 216 and 217: 202 Gas Turbine Handbook: Principle

- Page 218 and 219: This page intentionally left blank

- Page 220 and 221: 206 Gas Turbine Handbook: Principle

- Page 222 and 223: 208 Gas Turbine Handbook: Principle

- Page 224 and 225: 210 Gas Turbine Handbook: Principle

- Page 226 and 227: 212 Gas Turbine Handbook: Principle

- Page 228 and 229: 214 Gas Turbine Handbook: Principle

- Page 230 and 231: 216 Gas Turbine Handbook: Principle

- Page 232 and 233: 218 Gas Turbine Handbook: Principle

- Page 234 and 235: 220 Gas Turbine Handbook: Principle

- Page 236 and 237: 222 Gas Turbine Handbook: Principle

- Page 238 and 239: 224 Gas Turbine Handbook: Principle

- Page 240 and 241: 226 Gas Turbine Handbook: Principle

- Page 242 and 243: 228 Gas Turbine Handbook: Principle

- Page 244 and 245: 230 Gas Turbine Handbook: Principle

- Page 246 and 247: 232 Gas Turbine Handbook: Principle

- Page 248 and 249: 234 Gas Turbine Handbook: Principle

- Page 250 and 251: 236 Gas Turbine Handbook: Principle

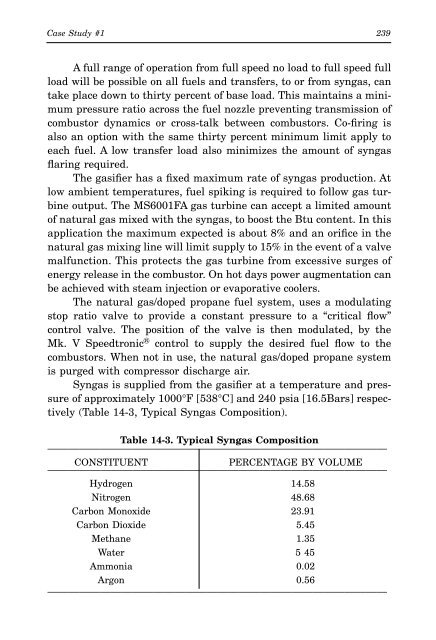

- Page 254 and 255: 240 Gas Turbine Handbook: Principle

- Page 256 and 257: 242 Gas Turbine Handbook: Principle

- Page 258 and 259: 244 Gas Turbine Handbook: Principle

- Page 260 and 261: 246 Gas Turbine Handbook: Principle

- Page 262 and 263: 248 Gas Turbine Handbook: Principle

- Page 264 and 265: 250 Gas Turbine Handbook: Principle

- Page 266 and 267: 252 Gas Turbine Handbook: Principle

- Page 268 and 269: 254 Gas Turbine Handbook: Principle

- Page 270 and 271: Figure 15-4. Corinth Motor Oil Refi

- Page 272 and 273: 258 Gas Turbine Handbook: Principle

- Page 274 and 275: 260 Gas Turbine Handbook: Principle

- Page 276 and 277: 262 Gas Turbine Handbook: Principle

- Page 278 and 279: 264 Gas Turbine Handbook: Principle

- Page 280 and 281: 266 Gas Turbine Handbook: Principle

- Page 282 and 283: 268 Gas Turbine Handbook: Principle

- Page 284 and 285: 270 Gas Turbine Handbook: Principle

- Page 286 and 287: 272 Gas Turbine Handbook: Principle

- Page 288 and 289: 274 Gas Turbine Handbook: Principle

- Page 290 and 291: 276 Gas Turbine Handbook: Principle

- Page 292 and 293: 278 Gas Turbine Handbook: Principle

- Page 294 and 295: 280 Gas Turbine Handbook: Principle

- Page 296 and 297: 282 Gas Turbine Handbook: Principle

- Page 298 and 299: 284 Gas Turbine Handbook: Principle

- Page 300 and 301: 286 Gas Turbine Handbook: Principle

- Page 302 and 303:

288 Gas Turbine Handbook: Principle

- Page 304 and 305:

290 Gas Turbine Handbook: Principle

- Page 306 and 307:

292 Gas Turbine Handbook: Principle

- Page 308 and 309:

294 Gas Turbine Handbook: Principle

- Page 310 and 311:

296 Gas Turbine Handbook: Principle

- Page 312 and 313:

298 Gas Turbine Handbook: Principle

- Page 314 and 315:

300 Gas Turbine Handbook: Principle

- Page 316 and 317:

302 Gas Turbine Handbook: Principle

- Page 318 and 319:

Appendix A-2 304 Gas Turbine Handbo

- Page 320 and 321:

306 Gas Turbine Handbook: Principle

- Page 322 and 323:

308 Gas Turbine Handbook: Principle

- Page 324 and 325:

310 Gas Turbine Handbook: Principle

- Page 326 and 327:

312 Gas Turbine Handbook: Principle

- Page 328 and 329:

314 Gas Turbine Handbook: Principle

- Page 330 and 331:

316 Gas Turbine Handbook: Principle

- Page 332 and 333:

318 Gas Turbine Handbook: Principle

- Page 334 and 335:

320 Gas Turbine Handbook: Principle

- Page 336 and 337:

322 Gas Turbine Handbook: Principle

- Page 338 and 339:

This page intentionally left blank

- Page 340 and 341:

326 Gas Turbine Handbook: Principle

- Page 342 and 343:

328 Gas Turbine Handbook: Principle

- Page 344 and 345:

330 Gas Turbine Handbook: Principle

- Page 346 and 347:

332 Gas Turbine Handbook: Principle

- Page 348 and 349:

334 Gas Turbine Handbook: Principle

- Page 350 and 351:

336 Gas Turbine Handbook: Principle

- Page 352 and 353:

338 Gas Turbine Handbook: Principle

- Page 354 and 355:

340 Gas Turbine Handbook: Principle

- Page 356 and 357:

342 Gas Turbine Handbook: Principle

- Page 358 and 359:

344 Gas Turbine Handbook: Principle

- Page 360 and 361:

346 Gas Turbine Handbook: Principle

- Page 362 and 363:

348 Gas Turbine Handbook: Principle

- Page 364 and 365:

350 Gas Turbine Handbook: Principle

- Page 366 and 367:

352 Gas Turbine Handbook: Principle

- Page 368 and 369:

354 Gas Turbine Handbook: Principle

- Page 370 and 371:

5. Weather Hood Material __________

- Page 372 and 373:

Appendix C-6 Air/Oil Cooler Specifi

- Page 374 and 375:

9. Drive Requirements A. Hydraulic

- Page 376 and 377:

22. Packaging For Shipment Per Spec

- Page 378 and 379:

Parameters Units NH 3 CO H 2 CH 4 C

- Page 380 and 381:

.055 Parameters Units 1/0 .88/.12 .

- Page 382 and 383:

Koppers Foster Blue Coal Gas Winkle

- Page 384 and 385:

370 Gas Turbine Handbook: Principle

- Page 386 and 387:

372 Gas Turbine Handbook: Principle

- Page 388 and 389:

374 Gas Turbine Handbook: Principle

- Page 390 and 391:

376 Gas Turbine Handbook: Principle

- Page 392 and 393:

378 Gas Turbine Handbook: Principle

- Page 394 and 395:

380 Gas Turbine Handbook: Principle

- Page 396 and 397:

382 Gas Turbine Handbook: Principle

- Page 398 and 399:

384 Gas Turbine Handbook: Principle

- Page 400 and 401:

386 Gas Turbine Handbook: Principle

- Page 402 and 403:

388 Gas Turbine Handbook: Principle

- Page 404 and 405:

This page intentionally left blank

- Page 406 and 407:

392 Gas Turbine Handbook: Principle

- Page 408 and 409:

394 Gas Turbine Handbook: Principle

- Page 410 and 411:

396 Gas Turbine Handbook: Principle

- Page 412 and 413:

398 Gas Turbine Handbook: Principle

- Page 414 and 415:

400 Gas Turbine Handbook: Principle

- Page 416 and 417:

402 Gas Turbine Handbook: Principle

- Page 418 and 419:

404 Gas Turbine Handbook: Principle

- Page 420 and 421:

406 Gas Turbine Handbook: Principle

- Page 422 and 423:

408 Gas Turbine Handbook: Principle

- Page 424 and 425:

410 Gas Turbine Handbook: Principle

- Page 426 and 427:

412 Gas Turbine Handbook: Principle

- Page 428 and 429:

414 Gas Turbine Handbook: Principle

- Page 430 and 431:

416 Gas Turbine Handbook: Principle

- Page 432 and 433:

418 Gas Turbine Handbook: Principle

- Page 434 and 435:

420 Gas Turbine Handbook: Principle

- Page 436 and 437:

422 Gas Turbine Handbook: Principle

- Page 438 and 439:

424 Gas Turbine Handbook: Principle

- Page 440 and 441:

This page intentionally left blank

- Page 442 and 443:

428 Gas Turbine Handbook: Principle

- Page 444 and 445:

430 Gas Turbine Handbook: Principle

- Page 446 and 447:

432 Gas Turbine Handbook: Principle

- Page 448 and 449:

434 Gas Turbine Handbook: Principle

- Page 450 and 451:

436 Gas Turbine Handbook: Principle