Pulacayo Project Feasibility Study - Apogee Silver

Pulacayo Project Feasibility Study - Apogee Silver

Pulacayo Project Feasibility Study - Apogee Silver

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Pulacayo</strong> 1 000 t/d Phase I <strong>Feasibility</strong> <strong>Study</strong> - NI 43-101 Technical Report<br />

090644-3-0000-20-IFI-100<br />

to the tailings storage facility (TSF) (at 70% solids) or it is pumped to the backfill plant. Paste<br />

is prepared by mixing thickened tailings (65% solids) with cement (6% w/w) to produce a<br />

flowing material to be deposited underground. The paste plant is designed to treat 100%<br />

tailings.<br />

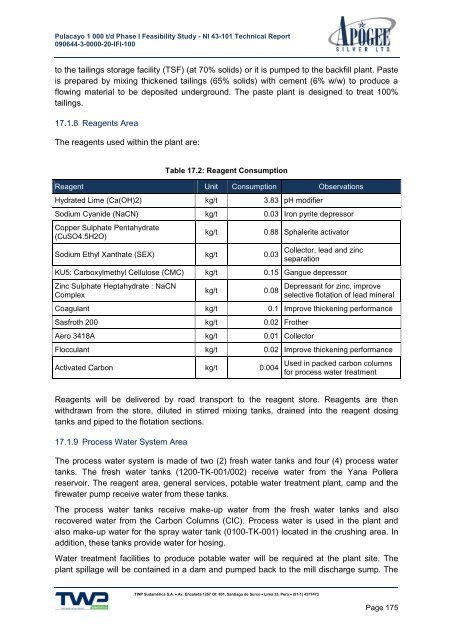

17.1.8 Reagents Area<br />

The reagents used within the plant are:<br />

Table 17.2: Reagent Consumption<br />

Reagent Unit Consumption Observations<br />

Hydrated Lime (Ca(OH)2) kg/t 3.83 pH modifier<br />

Sodium Cyanide (NaCN) kg/t 0.03 Iron pyrite depressor<br />

Copper Sulphate Pentahydrate<br />

(CuSO4.5H2O)<br />

kg/t<br />

Sodium Ethyl Xanthate (SEX) kg/t 0.03<br />

0.88 Sphalerite activator<br />

Collector, lead and zinc<br />

separation<br />

KU5: Carboxylmethyl Cellulose (CMC) kg/t 0.15 Gangue depressor<br />

Zinc Sulphate Heptahydrate : NaCN<br />

Complex<br />

kg/t<br />

0.08<br />

Depressant for zinc, improve<br />

selective flotation of lead mineral<br />

Coagulant kg/t 0.1 Improve thickening performance<br />

Sasfroth 200 kg/t 0.02 Frother<br />

Aero 3418A kg/t 0.01 Collector<br />

Flocculant kg/t 0.02 Improve thickening performance<br />

Activated Carbon kg/t 0.004<br />

Used in packed carbon columns<br />

for process water treatment<br />

Reagents will be delivered by road transport to the reagent store. Reagents are then<br />

withdrawn from the store, diluted in stirred mixing tanks, drained into the reagent dosing<br />

tanks and piped to the flotation sections.<br />

17.1.9 Process Water System Area<br />

The process water system is made of two (2) fresh water tanks and four (4) process water<br />

tanks. The fresh water tanks (1200-TK-001/002) receive water from the Yana Pollera<br />

reservoir. The reagent area, general services, potable water treatment plant, camp and the<br />

firewater pump receive water from these tanks.<br />

The process water tanks receive make-up water from the fresh water tanks and also<br />

recovered water from the Carbon Columns (CIC). Process water is used in the plant and<br />

also make-up water for the spray water tank (0100-TK-001) located in the crushing area. In<br />

addition, these tanks provide water for hosing.<br />

Water treatment facilities to produce potable water will be required at the plant site. The<br />

plant spillage will be contained in a dam and pumped back to the mill discharge sump. The<br />

TWP Sudamérica S.A. Av. Encalada 1257 Of. 801, Santiago de Surco Lima 33, Perú (51-1) 4377473<br />

Page 175