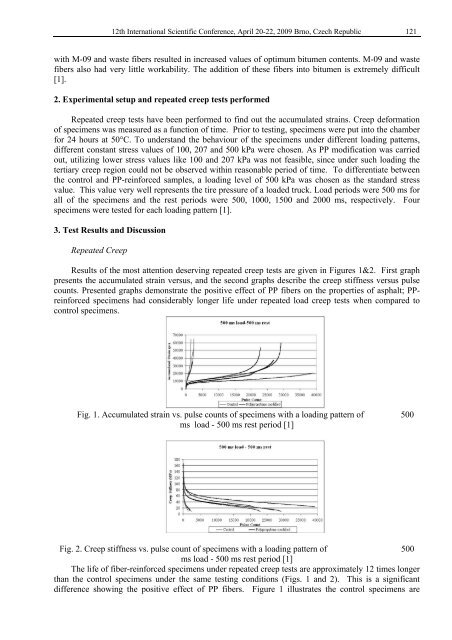

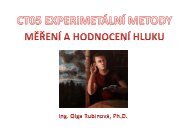

12th International Scientific Conference, April 20-22, 2009 Brno, Czech Republic 121with M-09 and waste fibers resulted in increased values of optimum bitumen contents. M-09 and wastefibers also had very little workability. The addition of these fibers into bitumen is extremely difficult[1].2. Experimental setup and repeated creep tests performedRepeated creep tests have been performed to find out the accumulated strains. Creep deformationof specimens was measured as a function of time. Prior to testing, specimens were put into the chamberfor 24 hours at 50°C. To understand the behaviour of the specimens under different loading patterns,different constant stress values of 100, 207 and 500 kPa were chosen. As PP modification was carriedout, utilizing lower stress values like 100 and 207 kPa was not feasible, since under such loading thetertiary creep region could not be observed within reasonable period of time. To differentiate betweenthe control and PP-reinforced samples, a loading level of 500 kPa was chosen as the standard stressvalue. This value very well represents the tire pressure of a loaded truck. Load periods were 500 ms forall of the specimens and the rest periods were 500, 1000, 1500 and 2000 ms, respectively. Fourspecimens were tested for each loading pattern [1].3. Test Results and DiscussionRepeated CreepResults of the most attention deserving repeated creep tests are given in Figures 1&2. First graphpresents the accumulated strain versus, and the second graphs describe the creep stiffness versus pulsecounts. Presented graphs demonstrate the positive effect of PP fibers on the properties of asphalt; PPreinforcedspecimens had considerably longer life under repeated load creep tests when compared tocontrol specimens.Fig. 1. Accumulated strain vs. pulse counts of specimens with a loading pattern of 500ms load - 500 ms rest period [1]Fig. 2. Creep stiffness vs. pulse count of specimens with a loading pattern of 500ms load - 500 ms rest period [1]The life of fiber-reinforced specimens under repeated creep tests are approximately 12 times longerthan the control specimens under the same testing conditions (Figs. 1 and 2). This is a significantdifference showing the positive effect of PP fibers. Figure 1 illustrates the control specimens are

12212th International Scientific Conference, April 20-22, 2009 Brno, Czech Republicentering to the tertiary stage of creep only at around 2000 pulse counts; this loading rate corresponds tothe primary creep stage for the PP fiber modified specimens. Fiber modified specimens reach thetertiary creep stage at the pulse counts of 20,000. At the end of the repeated creep tests, the controlspecimens have a total collapse, while the fiber reinforced specimens did not show any sign of failure.This observation implies the fiber modified specimens would have a considerable longer life than thecontrol specimen.Creep stiffness values drop at a certain level. For this study 10 MPa was the assumed creepstiffness. This level can be accepted as the termination of the test. For both specimen types, thetermination stiffness values are the same, but the pattern of the decrease in these values show a greatdifference (Fig. 2). When the control specimens fail, the creep stiffness of the fiber reinforcedspecimens have only dropped to their 50% values (i.e. the time required to fail for these specimens ismuch longer). In addition, the initial creep stiffness values of the fiber modified specimens arecorrespondingly higher vs. the control specimens, but because of the operating conditions of the UTM-5P system, an exact figure can not be determined.4. Conclusions and RecommendationsBased on the Marshall tests with fiber reinforced specimens, the optimum bitumen content wasfound to be 5.0%, the same as for the control specimens. The most suitable PP fiber, M-03 type, can beused at a dosage of 3‰ by the weight of the aggregates. The addition of the PP fibers into the asphaltmixture increased the Marshall stability values by 20% [1].The stiffness of the Marshall specimens has increased in a considerable manner, which is alsosupported by the visible increase in the Marshall Quotient values. The conclusion can be made that thelives of the fiber modified asphalt specimens under repeated creep loading at different loading patternsincreased by 5-12 times vs. control specimens. This is a very significant improvement. The repeatedcreep tests resulted in primary creep stage in case of the modified specimens, while the controlspecimens reached their tertiary creep stages. This fact is also well supported by the creep stiffnessvalues. While the control specimens are failing, the creep stiffness values in the fiber reinforcedspecimens have dropped only to 50% of their original values. The results from the analysis of the testedspecimens show that the addition of PP fibers improves the behaviour of the specimens by increasingthe life of samples under repeated creep testing. This is an important step in the generation of highperformance asphalt paving products. Also the more lighter asphalt products can lead to an importantremedy for flushing and bleeding problems [1].The static creep tests can be carried out on the PP fiber modified specimens at various loading andtemperature patterns. Also, PP fiber reinforcement of the bitumen can be examined by the aid of opticaland scanning electron microscopy. A further study will focus on the behaviour of the asphalt specimensat lower temperatures.References[1] TAPKIN, S., UŞAR, Ü., TUNCAN, A., AND TUNCAN, M., Repeated Creep Behaviour ofPolypropylene Fiber-Reinforced Bituminous Mixtures. Journal of Transportation Engineering,ASCE, 135(4), 2009, p. 240-249[2] FEELEY, A. J., UTM-5P, Universal testing machine, hardware reference manual, IndustrialProcess Controls Limited, 1994, Boronia, Australia[3] Highway technical specifications., Item No. 170/2, 2006, Ankara, Turkey.[4] TAPKIN, S., The effect of polypropylene fibers on asphalt performance. Building andEnvironment, 43, 2008, p. 1065–1071.