Dopravnàstavby - Fakulta stavebnà- Vysoké uÄÂenàtechnické v Brně

Dopravnàstavby - Fakulta stavebnà- Vysoké uÄÂenàtechnické v Brně

Dopravnàstavby - Fakulta stavebnà- Vysoké uÄÂenàtechnické v Brně

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

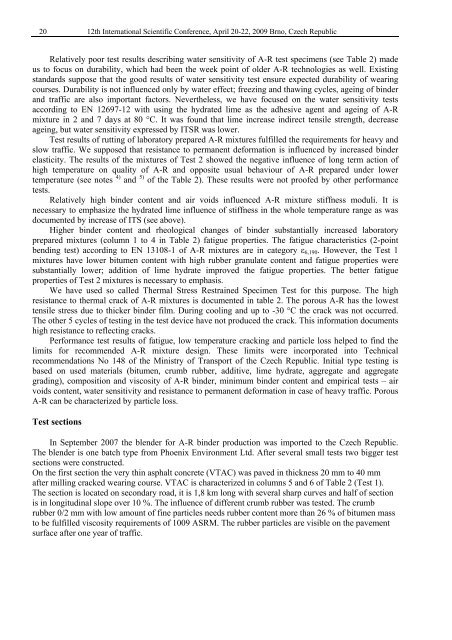

2012th International Scientific Conference, April 20-22, 2009 Brno, Czech RepublicRelatively poor test results describing water sensitivity of A-R test specimens (see Table 2) madeus to focus on durability, which had been the week point of older A-R technologies as well. Existingstandards suppose that the good results of water sensitivity test ensure expected durability of wearingcourses. Durability is not influenced only by water effect; freezing and thawing cycles, ageing of binderand traffic are also important factors. Nevertheless, we have focused on the water sensitivity testsaccording to EN 12697-12 with using the hydrated lime as the adhesive agent and ageing of A-Rmixture in 2 and 7 days at 80 °C. It was found that lime increase indirect tensile strength, decreaseageing, but water sensitivity expressed by ITSR was lower.Test results of rutting of laboratory prepared A-R mixtures fulfilled the requirements for heavy andslow traffic. We supposed that resistance to permanent deformation is influenced by increased binderelasticity. The results of the mixtures of Test 2 showed the negative influence of long term action ofhigh temperature on quality of A-R and opposite usual behaviour of A-R prepared under lowertemperature (see notes 4) and 5) of the Table 2). These results were not proofed by other performancetests.Relatively high binder content and air voids influenced A-R mixture stiffness moduli. It isnecessary to emphasize the hydrated lime influence of stiffness in the whole temperature range as wasdocumented by increase of ITS (see above).Higher binder content and rheological changes of binder substantially increased laboratoryprepared mixtures (column 1 to 4 in Table 2) fatigue properties. The fatigue characteristics (2-pointbending test) according to EN 13108-1 of A-R mixtures are in category ε 6,190 . However, the Test 1mixtures have lower bitumen content with high rubber granulate content and fatigue properties weresubstantially lower; addition of lime hydrate improved the fatigue properties. The better fatigueproperties of Test 2 mixtures is necessary to emphasis.We have used so called Thermal Stress Restrained Specimen Test for this purpose. The highresistance to thermal crack of A-R mixtures is documented in table 2. The porous A-R has the lowesttensile stress due to thicker binder film. During cooling and up to -30 °C the crack was not occurred.The other 5 cycles of testing in the test device have not produced the crack. This information documentshigh resistance to reflecting cracks.Performance test results of fatigue, low temperature cracking and particle loss helped to find thelimits for recommended A-R mixture design. These limits were incorporated into Technicalrecommendations No 148 of the Ministry of Transport of the Czech Republic. Initial type testing isbased on used materials (bitumen, crumb rubber, additive, lime hydrate, aggregate and aggregategrading), composition and viscosity of A-R binder, minimum binder content and empirical tests – airvoids content, water sensitivity and resistance to permanent deformation in case of heavy traffic. PorousA-R can be characterized by particle loss.Test sectionsIn September 2007 the blender for A-R binder production was imported to the Czech Republic.The blender is one batch type from Phoenix Environment Ltd. After several small tests two bigger testsections were constructed.On the first section the very thin asphalt concrete (VTAC) was paved in thickness 20 mm to 40 mmafter milling cracked wearing course. VTAC is characterized in columns 5 and 6 of Table 2 (Test 1).The section is located on secondary road, it is 1,8 km long with several sharp curves and half of sectionis in longitudinal slope over 10 %. The influence of different crumb rubber was tested. The crumbrubber 0/2 mm with low amount of fine particles needs rubber content more than 26 % of bitumen massto be fulfilled viscosity requirements of 1009 ASRM. The rubber particles are visible on the pavementsurface after one year of traffic.