Dopravnàstavby - Fakulta stavebnà- Vysoké uÄÂenàtechnické v Brně

Dopravnàstavby - Fakulta stavebnà- Vysoké uÄÂenàtechnické v Brně

Dopravnàstavby - Fakulta stavebnà- Vysoké uÄÂenàtechnické v Brně

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

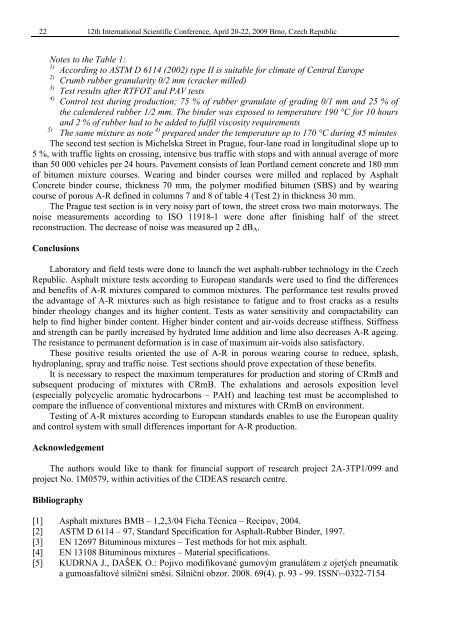

2212th International Scientific Conference, April 20-22, 2009 Brno, Czech RepublicNotes to the Table 1:1)According to ASTM D 6114 (2002) type II is suitable for climate of Central Europe2)Crumb rubber granularity 0/2 mm (cracker milled)3)Test results after RTFOT and PAV tests4)Control test during production; 75 % of rubber granulate of grading 0/1 mm and 25 % ofthe calendered rubber 1/2 mm. The binder was exposed to temperature 190 °C for 10 hoursand 2 % of rubber had to be added to fulfil viscosity requirements5)The same mixture as note 4) prepared under the temperature up to 170 °C during 45 minutesThe second test section is Michelska Street in Prague, four-lane road in longitudinal slope up to5 %, with traffic lights on crossing, intensive bus traffic with stops and with annual average of morethan 50 000 vehicles per 24 hours. Pavement consists of lean Portland cement concrete and 180 mmof bitumen mixture courses. Wearing and binder courses were milled and replaced by AsphaltConcrete binder course, thickness 70 mm, the polymer modified bitumen (SBS) and by wearingcourse of porous A-R defined in columns 7 and 8 of table 4 (Test 2) in thickness 30 mm.The Prague test section is in very noisy part of town, the street cross two main motorways. Thenoise measurements according to ISO 11918-1 were done after finishing half of the streetreconstruction. The decrease of noise was measured up 2 dB A .ConclusionsLaboratory and field tests were done to launch the wet asphalt-rubber technology in the CzechRepublic. Asphalt mixture tests according to European standards were used to find the differencesand benefits of A-R mixtures compared to common mixtures. The performance test results provedthe advantage of A-R mixtures such as high resistance to fatigue and to frost cracks as a resultsbinder rheology changes and its higher content. Tests as water sensitivity and compactability canhelp to find higher binder content. Higher binder content and air-voids decrease stiffness. Stiffnessand strength can be partly increased by hydrated lime addition and lime also decreases A-R ageing.The resistance to permanent deformation is in case of maximum air-voids also satisfactory.These positive results oriented the use of A-R in porous wearing course to reduce, splash,hydroplaning, spray and traffic noise. Test sections should prove expectation of these benefits.It is necessary to respect the maximum temperatures for production and storing of CRmB andsubsequent producing of mixtures with CRmB. The exhalations and aerosols exposition level(especially polycyclic aromatic hydrocarbons – PAH) and leaching test must be accomplished tocompare the influence of conventional mixtures and mixtures with CRmB on environment.Testing of A-R mixtures according to European standards enables to use the European qualityand control system with small differences important for A-R production.AcknowledgementThe authors would like to thank for financial support of research project 2A-3TP1/099 andproject No. 1M0579, within activities of the CIDEAS research centre.Bibliography[1] Asphalt mixtures BMB – 1,2,3/04 Ficha Técnica – Recipav, 2004.[2] ASTM D 6114 – 97, Standard Specification for Asphalt-Rubber Binder, 1997.[3] EN 12697 Bituminous mixtures – Test methods for hot mix asphalt.[4] EN 13108 Bituminous mixtures – Material specifications.[5] KUDRNA J., DAŠEK O.: Pojivo modifikované gumovým granulátem z ojetých pneumatika gumoasfaltové silniční směsi. Silniční obzor. 2008. 69(4). p. 93 - 99. ISSN\~0322-7154