Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

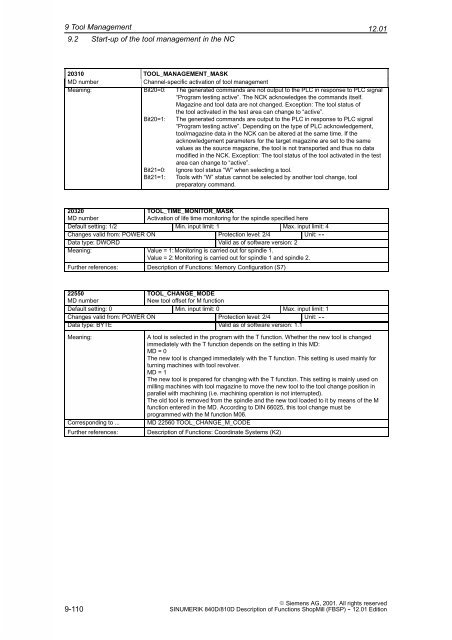

9ToolManagement 9.2 Start-up of the tool management in the NC<br />

9-110<br />

12.01<br />

20310 TOOL_MANAGEMENT_MASK<br />

MD number Channel-specific activation of tool management<br />

Meaning: Bit20=0: The generated commands are not output to the PLC in response to PLC signal<br />

“Program testing active”. The NCK acknowledges the commands itself.<br />

Magazine and tool data are not changed. Exception: The tool status of<br />

the tool activated in the test area can change to “active”.<br />

Bit20=1: The generated commands are output to the PLC in response to PLC signal<br />

“Program testing active”. Depending on the type of PLC acknowledgement,<br />

tool/magazine data in the NCK can be altered at the same time. If the<br />

acknowledgement parameters for the target magazine are set to the same<br />

values as the source magazine, the tool is not transported and thus no data<br />

modified in the NCK. Exception: The tool status of the tool activated in the test<br />

area can change to “active”.<br />

Bit21=0: Ignore tool status “W” when selecting a tool.<br />

Bit21=1: Tools with “W” status cannot be selected by another tool change, tool<br />

preparatory command.<br />

20320<br />

TOOL_TIME_MONITOR_MASK<br />

MD number<br />

Activation of life time monitoring for the spindle specified here<br />

Default setting: 1/2 Min. input limit: 1 Max. input limit: 4<br />

Changes valid from: POWER ON Protection level: 2/4 Unit: - -<br />

Data type: DWORD Valid as of software version: 2<br />

Meaning: Value = 1: Monitoring is carried out for spindle 1.<br />

Value = 2: Monitoring is carried out for spindle 1 and spindle 2.<br />

Further references: Description of Functions: Memory Configuration (S7)<br />

22550<br />

TOOL_CHANGE_MODE<br />

MD number<br />

New tool offset for M function<br />

Default setting: 0 Min. input limit: 0 Max. input limit: 1<br />

Changes valid from: POWER ON Protection level: 2/4 Unit: - -<br />

Data type: BYTE Valid as of software version: 1.1<br />

Meaning: A tool is selected in the program with the T function. Whether the new tool is changed<br />

immediately with the T function depends on the setting in this MD:<br />

MD = 0<br />

The new tool is changed immediately with the T function. This setting is used mainly for<br />

turning machines with tool revolver.<br />

MD = 1<br />

The new tool is prepared for changing with the T function. This setting is mainly used on<br />

milling machines with tool magazine to move the new tool to the tool change position in<br />

parallel with machining (i.e. machining operation is not interrupted).<br />

The old tool is removed from the spindle and the new tool loaded to it by means of the M<br />

function entered in the MD. According to DIN 66025, this tool change must be<br />

programmed with the M function M06.<br />

Corresponding to ... MD 22560 TOOL_CHANGE_M_CODE<br />

Further references: Description of Functions: Coordinate Systems (K2)<br />

E Siemens AG, 2001. All rights reserved<br />

<strong>SINUMERIK</strong> <strong>840D</strong>/<strong>810D</strong> Description of Functions <strong>ShopMill</strong> (FBSP) - 12.01 Edition