Studies on the use of nano zinc oxide and modified silica in NR, CR ...

Studies on the use of nano zinc oxide and modified silica in NR, CR ...

Studies on the use of nano zinc oxide and modified silica in NR, CR ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Chapter 5<br />

97<br />

O<strong>the</strong>r technological properties like hardness, compressi<strong>on</strong> set values<br />

<strong>and</strong> abrasi<strong>on</strong> loss for gum vulcanizates are given <strong>in</strong> Table5.5. Hardness,<br />

compressi<strong>on</strong> set <strong>and</strong> abrasi<strong>on</strong> loss for C-1, C-2, <strong>and</strong> C-3 vulcanizates are<br />

superior compared to C-4 vulcanizate. It is clear from <strong>the</strong> table that <strong>the</strong><br />

hardness <strong>and</strong> compressi<strong>on</strong> set values <strong>of</strong> C-2 <strong>and</strong> C-3 vulcanizates are<br />

comparable with C-1 vulcanizate. The abrasi<strong>on</strong> loss values for C-2 <strong>and</strong> C-3<br />

vulcanizates are reduced compared to C-1 vulcanizate. This <strong>in</strong>dicates that low<br />

dosage <strong>of</strong> ZnO(p) <strong>and</strong> ZnO(s) are enough to get <strong>the</strong> same strength as that<br />

with higher dosage <strong>of</strong> c<strong>on</strong>venti<strong>on</strong>al ZnO. This may be due to <strong>the</strong> smaller<br />

particle size <strong>of</strong> ZnO(p) <strong>and</strong> ZnO(s). 8<br />

5.3.3 Properties <strong>of</strong> filled vulcanizates<br />

Tensile properties<br />

Composite<br />

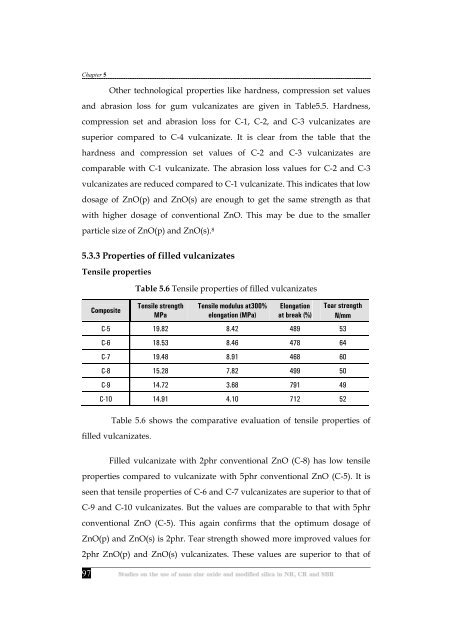

Table 5.6 Tensile properties <strong>of</strong> filled vulcanizates<br />

Tensile strength<br />

MPa<br />

Tensile modulus at300%<br />

el<strong>on</strong>gati<strong>on</strong> (MPa)<br />

El<strong>on</strong>gati<strong>on</strong><br />

at break (%)<br />

Tear strength<br />

N/mm<br />

C-5 19.82 8.42 489 53<br />

C-6 18.53 8.46 478 64<br />

C-7 19.48 8.91 468 60<br />

C-8 15.28 7.82 499 50<br />

C-9 14.72 3.68 791 49<br />

C-10 14.91 4.10 712 52<br />

Table 5.6 shows <strong>the</strong> comparative evaluati<strong>on</strong> <strong>of</strong> tensile properties <strong>of</strong><br />

filled vulcanizates.<br />

Filled vulcanizate with 2phr c<strong>on</strong>venti<strong>on</strong>al ZnO (C-8) has low tensile<br />

properties compared to vulcanizate with 5phr c<strong>on</strong>venti<strong>on</strong>al ZnO (C-5). It is<br />

seen that tensile properties <strong>of</strong> C-6 <strong>and</strong> C-7 vulcanizates are superior to that <strong>of</strong><br />

C-9 <strong>and</strong> C-10 vulcanizates. But <strong>the</strong> values are comparable to that with 5phr<br />

c<strong>on</strong>venti<strong>on</strong>al ZnO (C-5). This aga<strong>in</strong> c<strong>on</strong>firms that <strong>the</strong> optimum dosage <strong>of</strong><br />

ZnO(p) <strong>and</strong> ZnO(s) is 2phr. Tear strength showed more improved values for<br />

2phr ZnO(p) <strong>and</strong> ZnO(s) vulcanizates. These values are superior to that <strong>of</strong>