Studies on the use of nano zinc oxide and modified silica in NR, CR ...

Studies on the use of nano zinc oxide and modified silica in NR, CR ...

Studies on the use of nano zinc oxide and modified silica in NR, CR ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Mix<br />

Use <strong>of</strong> antioxidant <strong>modified</strong> precipitated <strong>silica</strong> <strong>in</strong> natural rubber,<br />

chloroprene rubber <strong>and</strong> styrene butadiene rubber<br />

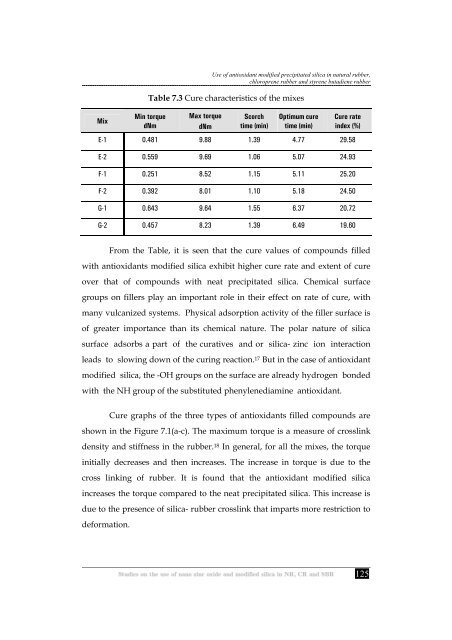

Table 7.3 Cure characteristics <strong>of</strong> <strong>the</strong> mixes<br />

M<strong>in</strong> torque<br />

dNm<br />

Max torque<br />

dNm<br />

Scorch<br />

time (m<strong>in</strong>)<br />

Optimum cure<br />

time (m<strong>in</strong>)<br />

Cure rate<br />

<strong>in</strong>dex (%)<br />

E-1 0.481 9.88 1.39 4.77 29.58<br />

E-2 0.559 9.69 1.06 5.07 24.93<br />

F-1 0.251 8.52 1.15 5.11 25.20<br />

F-2 0.392 8.01 1.10 5.18 24.50<br />

G-1 0.643 9.64 1.55 6.37 20.72<br />

G-2 0.457 8.23 1.39 6.49 19.60<br />

From <strong>the</strong> Table, it is seen that <strong>the</strong> cure values <strong>of</strong> compounds filled<br />

with antioxidants <strong>modified</strong> <strong>silica</strong> exhibit higher cure rate <strong>and</strong> extent <strong>of</strong> cure<br />

over that <strong>of</strong> compounds with neat precipitated <strong>silica</strong>. Chemical surface<br />

groups <strong>on</strong> fillers play an important role <strong>in</strong> <strong>the</strong>ir effect <strong>on</strong> rate <strong>of</strong> cure, with<br />

many vulcanized systems. Physical adsorpti<strong>on</strong> activity <strong>of</strong> <strong>the</strong> filler surface is<br />

<strong>of</strong> greater importance than its chemical nature. The polar nature <strong>of</strong> <strong>silica</strong><br />

surface adsorbs a part <strong>of</strong> <strong>the</strong> curatives <strong>and</strong> or <strong>silica</strong>- <strong>z<strong>in</strong>c</strong> i<strong>on</strong> <strong>in</strong>teracti<strong>on</strong><br />

leads to slow<strong>in</strong>g down <strong>of</strong> <strong>the</strong> cur<strong>in</strong>g reacti<strong>on</strong>. 17 But <strong>in</strong> <strong>the</strong> case <strong>of</strong> antioxidant<br />

<strong>modified</strong> <strong>silica</strong>, <strong>the</strong> -OH groups <strong>on</strong> <strong>the</strong> surface are already hydrogen b<strong>on</strong>ded<br />

with <strong>the</strong> NH group <strong>of</strong> <strong>the</strong> substituted phenylenediam<strong>in</strong>e antioxidant.<br />

Cure graphs <strong>of</strong> <strong>the</strong> three types <strong>of</strong> antioxidants filled compounds are<br />

shown <strong>in</strong> <strong>the</strong> Figure 7.1(a-c). The maximum torque is a measure <strong>of</strong> crossl<strong>in</strong>k<br />

density <strong>and</strong> stiffness <strong>in</strong> <strong>the</strong> rubber. 18 In general, for all <strong>the</strong> mixes, <strong>the</strong> torque<br />

<strong>in</strong>itially decreases <strong>and</strong> <strong>the</strong>n <strong>in</strong>creases. The <strong>in</strong>crease <strong>in</strong> torque is due to <strong>the</strong><br />

cross l<strong>in</strong>k<strong>in</strong>g <strong>of</strong> rubber. It is found that <strong>the</strong> antioxidant <strong>modified</strong> <strong>silica</strong><br />

<strong>in</strong>creases <strong>the</strong> torque compared to <strong>the</strong> neat precipitated <strong>silica</strong>. This <strong>in</strong>crease is<br />

due to <strong>the</strong> presence <strong>of</strong> <strong>silica</strong>- rubber crossl<strong>in</strong>k that imparts more restricti<strong>on</strong> to<br />

deformati<strong>on</strong>.<br />

125