Studies on the use of nano zinc oxide and modified silica in NR, CR ...

Studies on the use of nano zinc oxide and modified silica in NR, CR ...

Studies on the use of nano zinc oxide and modified silica in NR, CR ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Use <strong>of</strong> antioxidant <strong>modified</strong> precipitated <strong>silica</strong> <strong>in</strong> natural rubber,<br />

chloroprene rubber <strong>and</strong> styrene butadiene rubber<br />

mix <strong>in</strong>creases <strong>the</strong> torque values. The maximum torque is <strong>the</strong> measure <strong>of</strong><br />

crossl<strong>in</strong>k density <strong>and</strong> stiffness <strong>in</strong> <strong>the</strong> rubber. This <strong>in</strong>crease <strong>in</strong> torque value for<br />

antioxidant <strong>modified</strong> <strong>silica</strong> mix may be due to <strong>the</strong> surface modificati<strong>on</strong> <strong>of</strong><br />

<strong>silica</strong> with antioxidant.<br />

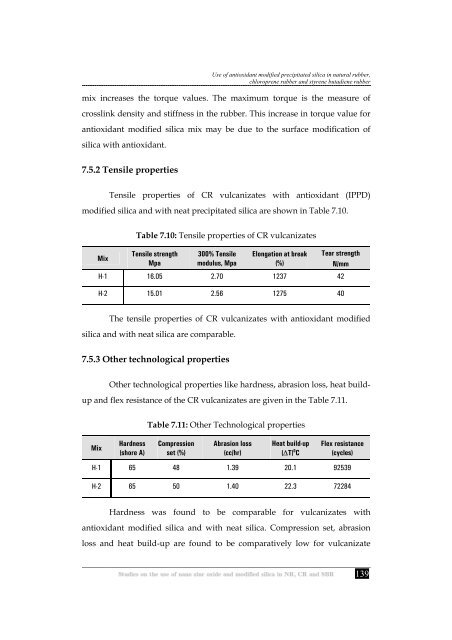

7.5.2 Tensile properties<br />

Tensile properties <strong>of</strong> <strong>CR</strong> vulcanizates with antioxidant (IPPD)<br />

<strong>modified</strong> <strong>silica</strong> <strong>and</strong> with neat precipitated <strong>silica</strong> are shown <strong>in</strong> Table 7.10.<br />

Mix<br />

Table 7.10: Tensile properties <strong>of</strong> <strong>CR</strong> vulcanizates<br />

Tensile strength<br />

Mpa<br />

300% Tensile<br />

modulus, Mpa<br />

El<strong>on</strong>gati<strong>on</strong> at break<br />

(%)<br />

Tear strength<br />

N/mm<br />

H-1 16.05 2.70 1237 42<br />

H-2 15.01 2.56 1275 40<br />

The tensile properties <strong>of</strong> <strong>CR</strong> vulcanizates with antioxidant <strong>modified</strong><br />

<strong>silica</strong> <strong>and</strong> with neat <strong>silica</strong> are comparable.<br />

7.5.3 O<strong>the</strong>r technological properties<br />

O<strong>the</strong>r technological properties like hardness, abrasi<strong>on</strong> loss, heat build-<br />

up <strong>and</strong> flex resistance <strong>of</strong> <strong>the</strong> <strong>CR</strong> vulcanizates are given <strong>in</strong> <strong>the</strong> Table 7.11.<br />

Mix<br />

Hardness<br />

(shore A)<br />

Table 7.11: O<strong>the</strong>r Technological properties<br />

Compressi<strong>on</strong><br />

set (%)<br />

Abrasi<strong>on</strong> loss<br />

(cc/hr)<br />

Heat build-up<br />

(∆T) 0 C<br />

Flex resistance<br />

(cycles)<br />

H-1 65 48 1.39 20.1 92539<br />

H-2 65 50 1.40 22.3 72284<br />

Hardness was found to be comparable for vulcanizates with<br />

antioxidant <strong>modified</strong> <strong>silica</strong> <strong>and</strong> with neat <strong>silica</strong>. Compressi<strong>on</strong> set, abrasi<strong>on</strong><br />

loss <strong>and</strong> heat build-up are found to be comparatively low for vulcanizate<br />

139