Studies on the use of nano zinc oxide and modified silica in NR, CR ...

Studies on the use of nano zinc oxide and modified silica in NR, CR ...

Studies on the use of nano zinc oxide and modified silica in NR, CR ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Products from rice husk as filler <strong>in</strong> natural rubber<br />

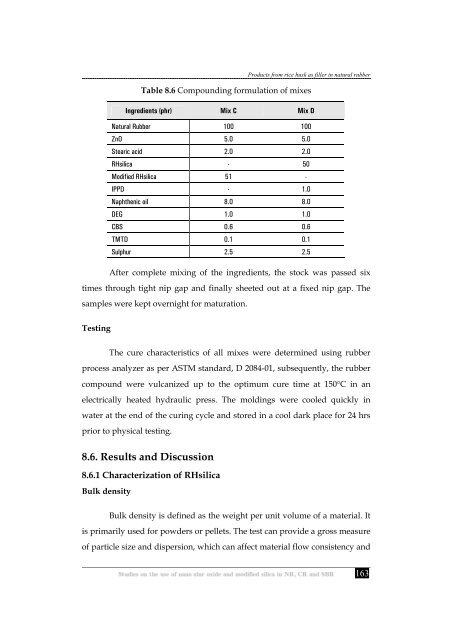

Table 8.6 Compound<strong>in</strong>g formulati<strong>on</strong> <strong>of</strong> mixes<br />

Ingredients (phr) Mix C Mix D<br />

Natural Rubber 100 100<br />

ZnO 5.0 5.0<br />

Stearic acid 2.0 2.0<br />

RH<strong>silica</strong> - 50<br />

Modified RH<strong>silica</strong> 51 -<br />

IPPD - 1.0<br />

Naph<strong>the</strong>nic oil 8.0 8.0<br />

DEG 1.0 1.0<br />

CBS 0.6 0.6<br />

TMTD 0.1 0.1<br />

Sulphur 2.5 2.5<br />

After complete mix<strong>in</strong>g <strong>of</strong> <strong>the</strong> <strong>in</strong>gredients, <strong>the</strong> stock was passed six<br />

times through tight nip gap <strong>and</strong> f<strong>in</strong>ally sheeted out at a fixed nip gap. The<br />

samples were kept overnight for maturati<strong>on</strong>.<br />

Test<strong>in</strong>g<br />

The cure characteristics <strong>of</strong> all mixes were determ<strong>in</strong>ed us<strong>in</strong>g rubber<br />

process analyzer as per ASTM st<strong>and</strong>ard, D 2084-01, subsequently, <strong>the</strong> rubber<br />

compound were vulcanized up to <strong>the</strong> optimum cure time at 150°C <strong>in</strong> an<br />

electrically heated hydraulic press. The mold<strong>in</strong>gs were cooled quickly <strong>in</strong><br />

water at <strong>the</strong> end <strong>of</strong> <strong>the</strong> cur<strong>in</strong>g cycle <strong>and</strong> stored <strong>in</strong> a cool dark place for 24 hrs<br />

prior to physical test<strong>in</strong>g.<br />

8.6. Results <strong>and</strong> Discussi<strong>on</strong><br />

8.6.1 Characterizati<strong>on</strong> <strong>of</strong> RH<strong>silica</strong><br />

Bulk density<br />

Bulk density is def<strong>in</strong>ed as <strong>the</strong> weight per unit volume <strong>of</strong> a material. It<br />

is primarily <strong>use</strong>d for powders or pellets. The test can provide a gross measure<br />

<strong>of</strong> particle size <strong>and</strong> dispersi<strong>on</strong>, which can affect material flow c<strong>on</strong>sistency <strong>and</strong><br />

163