Studies on the use of nano zinc oxide and modified silica in NR, CR ...

Studies on the use of nano zinc oxide and modified silica in NR, CR ...

Studies on the use of nano zinc oxide and modified silica in NR, CR ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Use <strong>of</strong> antioxidant <strong>modified</strong> precipitated <strong>silica</strong> <strong>in</strong> natural rubber,<br />

chloroprene rubber <strong>and</strong> styrene butadiene rubber<br />

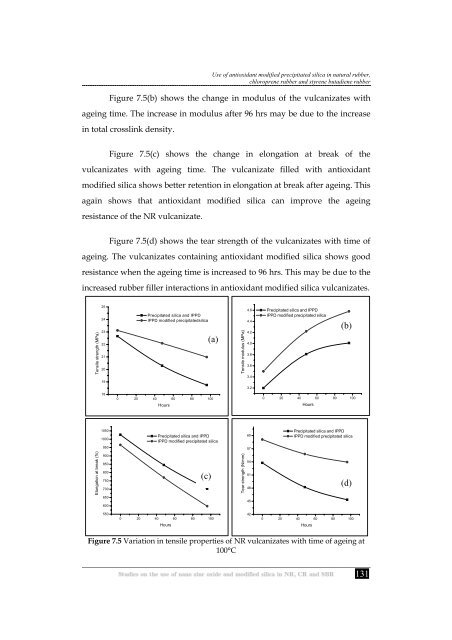

Figure 7.5(b) shows <strong>the</strong> change <strong>in</strong> modulus <strong>of</strong> <strong>the</strong> vulcanizates with<br />

age<strong>in</strong>g time. The <strong>in</strong>crease <strong>in</strong> modulus after 96 hrs may be due to <strong>the</strong> <strong>in</strong>crease<br />

<strong>in</strong> total crossl<strong>in</strong>k density.<br />

Figure 7.5(c) shows <strong>the</strong> change <strong>in</strong> el<strong>on</strong>gati<strong>on</strong> at break <strong>of</strong> <strong>the</strong><br />

vulcanizates with age<strong>in</strong>g time. The vulcanizate filled with antioxidant<br />

<strong>modified</strong> <strong>silica</strong> shows better retenti<strong>on</strong> <strong>in</strong> el<strong>on</strong>gati<strong>on</strong> at break after age<strong>in</strong>g. This<br />

aga<strong>in</strong> shows that antioxidant <strong>modified</strong> <strong>silica</strong> can improve <strong>the</strong> age<strong>in</strong>g<br />

resistance <strong>of</strong> <strong>the</strong> <strong>NR</strong> vulcanizate.<br />

Figure 7.5(d) shows <strong>the</strong> tear strength <strong>of</strong> <strong>the</strong> vulcanizates with time <strong>of</strong><br />

age<strong>in</strong>g. The vulcanizates c<strong>on</strong>ta<strong>in</strong><strong>in</strong>g antioxidant <strong>modified</strong> <strong>silica</strong> shows good<br />

resistance when <strong>the</strong> age<strong>in</strong>g time is <strong>in</strong>creased to 96 hrs. This may be due to <strong>the</strong><br />

<strong>in</strong>creased rubber filler <strong>in</strong>teracti<strong>on</strong>s <strong>in</strong> antioxidant <strong>modified</strong> <strong>silica</strong> vulcanizates.<br />

Tensile strength (MPa)<br />

El<strong>on</strong>gati<strong>on</strong> at break (%)<br />

25<br />

24<br />

23<br />

22<br />

21<br />

20<br />

19<br />

18<br />

1050<br />

1000<br />

950<br />

900<br />

850<br />

800<br />

750<br />

700<br />

650<br />

600<br />

550<br />

Precipitated <strong>silica</strong> <strong>and</strong> IPPD<br />

IPPD <strong>modified</strong> precipitated<strong>silica</strong><br />

0 20 40 60 80 100<br />

Hours<br />

Precipitated <strong>silica</strong> <strong>and</strong> IPPD<br />

IPPD <strong>modified</strong> precipitated <strong>silica</strong><br />

0 20 40 60 80 100<br />

Hours<br />

(c)<br />

(a)<br />

0 20 40 60 80 100<br />

Figure 7.5 Variati<strong>on</strong> <strong>in</strong> tensile properties <strong>of</strong> <strong>NR</strong> vulcanizates with time <strong>of</strong> age<strong>in</strong>g at<br />

100°C<br />

Tensile modulus (MPa)<br />

Tear strength (N/mm)<br />

4.6<br />

4.4<br />

4.2<br />

4.0<br />

3.8<br />

3.6<br />

3.4<br />

3.2<br />

60<br />

57<br />

54<br />

51<br />

48<br />

45<br />

42<br />

Precipitated <strong>silica</strong> <strong>and</strong> IPPD<br />

IPPD <strong>modified</strong> precipitated <strong>silica</strong><br />

Hours<br />

(b)<br />

Precipitated <strong>silica</strong> <strong>and</strong> IPPD<br />

IPPD <strong>modified</strong> precipitated <strong>silica</strong><br />

(d)<br />

0 20 40 60 80 100<br />

Hours<br />

131