Studies on the use of nano zinc oxide and modified silica in NR, CR ...

Studies on the use of nano zinc oxide and modified silica in NR, CR ...

Studies on the use of nano zinc oxide and modified silica in NR, CR ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Chapter 7<br />

<strong>silica</strong> particles are reduced by <strong>the</strong> antioxidant which acts as lubricants. So it<br />

reduces <strong>the</strong> heat developed by <strong>the</strong> fricti<strong>on</strong>al stra<strong>in</strong>.<br />

7.3.5 Rubber-filler <strong>in</strong>teracti<strong>on</strong> studies<br />

With antioxidant IPPD<br />

130<br />

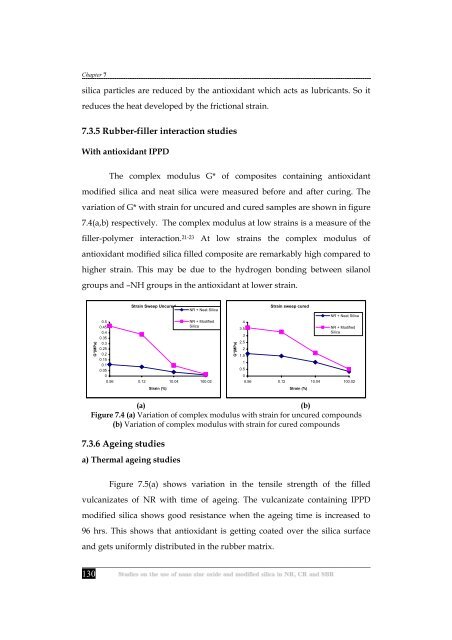

The complex modulus G* <strong>of</strong> composites c<strong>on</strong>ta<strong>in</strong><strong>in</strong>g antioxidant<br />

<strong>modified</strong> <strong>silica</strong> <strong>and</strong> neat <strong>silica</strong> were measured before <strong>and</strong> after cur<strong>in</strong>g. The<br />

variati<strong>on</strong> <strong>of</strong> G* with stra<strong>in</strong> for uncured <strong>and</strong> cured samples are shown <strong>in</strong> figure<br />

7.4(a,b) respectively. The complex modulus at low stra<strong>in</strong>s is a measure <strong>of</strong> <strong>the</strong><br />

filler-polymer <strong>in</strong>teracti<strong>on</strong>. 21-23 At low stra<strong>in</strong>s <strong>the</strong> complex modulus <strong>of</strong><br />

antioxidant <strong>modified</strong> <strong>silica</strong> filled composite are remarkably high compared to<br />

higher stra<strong>in</strong>. This may be due to <strong>the</strong> hydrogen b<strong>on</strong>d<strong>in</strong>g between silanol<br />

groups <strong>and</strong> –NH groups <strong>in</strong> <strong>the</strong> antioxidant at lower stra<strong>in</strong>.<br />

G*(MPa)<br />

0.5<br />

0.45<br />

0.4<br />

0.35<br />

0.3<br />

0.25<br />

0.2<br />

0.15<br />

0.1<br />

0.05<br />

0<br />

Stra<strong>in</strong> Sweep Uncured<br />

<strong>NR</strong> + Neat Silica<br />

<strong>NR</strong> + Modified<br />

Silica<br />

0.56 0.12 10.04 100.02<br />

Stra<strong>in</strong> (%)<br />

G*(MPa)<br />

4<br />

3.5<br />

3<br />

2.5<br />

2<br />

1.5<br />

1<br />

0.5<br />

0<br />

Stra<strong>in</strong> sweep cured<br />

<strong>NR</strong> + Neat Silica<br />

<strong>NR</strong> + Modified<br />

Silica<br />

0.56 0.12 10.04 100.02<br />

Stra<strong>in</strong> (%)<br />

(a) (b)<br />

Figure 7.4 (a) Variati<strong>on</strong> <strong>of</strong> complex modulus with stra<strong>in</strong> for uncured compounds<br />

(b) Variati<strong>on</strong> <strong>of</strong> complex modulus with stra<strong>in</strong> for cured compounds<br />

7.3.6 Age<strong>in</strong>g studies<br />

a) Thermal age<strong>in</strong>g studies<br />

Figure 7.5(a) shows variati<strong>on</strong> <strong>in</strong> <strong>the</strong> tensile strength <strong>of</strong> <strong>the</strong> filled<br />

vulcanizates <strong>of</strong> <strong>NR</strong> with time <strong>of</strong> age<strong>in</strong>g. The vulcanizate c<strong>on</strong>ta<strong>in</strong><strong>in</strong>g IPPD<br />

<strong>modified</strong> <strong>silica</strong> shows good resistance when <strong>the</strong> age<strong>in</strong>g time is <strong>in</strong>creased to<br />

96 hrs. This shows that antioxidant is gett<strong>in</strong>g coated over <strong>the</strong> <strong>silica</strong> surface<br />

<strong>and</strong> gets uniformly distributed <strong>in</strong> <strong>the</strong> rubber matrix.