Studies on the use of nano zinc oxide and modified silica in NR, CR ...

Studies on the use of nano zinc oxide and modified silica in NR, CR ...

Studies on the use of nano zinc oxide and modified silica in NR, CR ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Chapter 8<br />

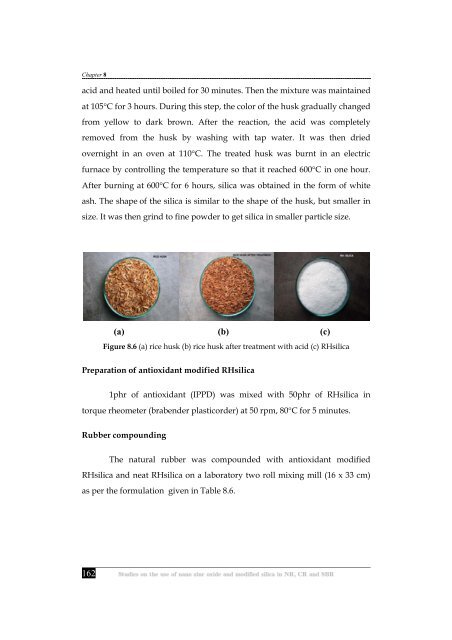

acid <strong>and</strong> heated until boiled for 30 m<strong>in</strong>utes. Then <strong>the</strong> mixture was ma<strong>in</strong>ta<strong>in</strong>ed<br />

at 105°C for 3 hours. Dur<strong>in</strong>g this step, <strong>the</strong> color <strong>of</strong> <strong>the</strong> husk gradually changed<br />

from yellow to dark brown. After <strong>the</strong> reacti<strong>on</strong>, <strong>the</strong> acid was completely<br />

removed from <strong>the</strong> husk by wash<strong>in</strong>g with tap water. It was <strong>the</strong>n dried<br />

overnight <strong>in</strong> an oven at 110°C. The treated husk was burnt <strong>in</strong> an electric<br />

furnace by c<strong>on</strong>troll<strong>in</strong>g <strong>the</strong> temperature so that it reached 600°C <strong>in</strong> <strong>on</strong>e hour.<br />

After burn<strong>in</strong>g at 600°C for 6 hours, <strong>silica</strong> was obta<strong>in</strong>ed <strong>in</strong> <strong>the</strong> form <strong>of</strong> white<br />

ash. The shape <strong>of</strong> <strong>the</strong> <strong>silica</strong> is similar to <strong>the</strong> shape <strong>of</strong> <strong>the</strong> husk, but smaller <strong>in</strong><br />

size. It was <strong>the</strong>n gr<strong>in</strong>d to f<strong>in</strong>e powder to get <strong>silica</strong> <strong>in</strong> smaller particle size.<br />

162<br />

(a) (b) (c)<br />

Figure 8.6 (a) rice husk (b) rice husk after treatment with acid (c) RH<strong>silica</strong><br />

Preparati<strong>on</strong> <strong>of</strong> antioxidant <strong>modified</strong> RH<strong>silica</strong><br />

1phr <strong>of</strong> antioxidant (IPPD) was mixed with 50phr <strong>of</strong> RH<strong>silica</strong> <strong>in</strong><br />

torque rheometer (brabender plasticorder) at 50 rpm, 80°C for 5 m<strong>in</strong>utes.<br />

Rubber compound<strong>in</strong>g<br />

The natural rubber was compounded with antioxidant <strong>modified</strong><br />

RH<strong>silica</strong> <strong>and</strong> neat RH<strong>silica</strong> <strong>on</strong> a laboratory two roll mix<strong>in</strong>g mill (16 x 33 cm)<br />

as per <strong>the</strong> formulati<strong>on</strong> given <strong>in</strong> Table 8.6.