Studies on the use of nano zinc oxide and modified silica in NR, CR ...

Studies on the use of nano zinc oxide and modified silica in NR, CR ...

Studies on the use of nano zinc oxide and modified silica in NR, CR ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Use <strong>of</strong> <strong>nano</strong> <strong>z<strong>in</strong>c</strong> <strong>oxide</strong> <strong>in</strong> natural rubber<br />

Cure behavior <strong>of</strong> gum <strong>and</strong> filled compounds are given <strong>in</strong> <strong>the</strong> Table 4.3<br />

<strong>and</strong> figure 4.1. Compar<strong>in</strong>g <strong>the</strong> cure characteristics <strong>of</strong> filled <strong>and</strong> gum<br />

compounds, compounds with 2phr ZnO(p) <strong>and</strong> ZnO(s) exhibited higher rate<br />

<strong>and</strong> extent <strong>of</strong> cure over that <strong>of</strong> 5phr <strong>and</strong> 2phr <strong>of</strong> c<strong>on</strong>venti<strong>on</strong>al ZnO<br />

compounds. This <strong>in</strong>dicates ZnO(p) <strong>and</strong> ZnO(s) with larger surface area<br />

developed <strong>the</strong> full potential <strong>of</strong> <strong>the</strong> accelerator, <strong>the</strong>re by mak<strong>in</strong>g vulcanizati<strong>on</strong><br />

faster. Scorch safety has <strong>in</strong>creased, <strong>and</strong> cure time was found to be lower<br />

for ZnO(p) <strong>and</strong> ZnO(s) compounds compared to c<strong>on</strong>venti<strong>on</strong>al ZnO<br />

compounds. Compounds with 2phr ZnO(p) <strong>and</strong> ZnO(s) show faster cur<strong>in</strong>g<br />

compared to compounds c<strong>on</strong>ta<strong>in</strong><strong>in</strong>g 1phr ZnO(p) <strong>and</strong> ZnO(s).<br />

4.3.2 Properties <strong>of</strong> gum composites<br />

Tensile properties<br />

Compound<br />

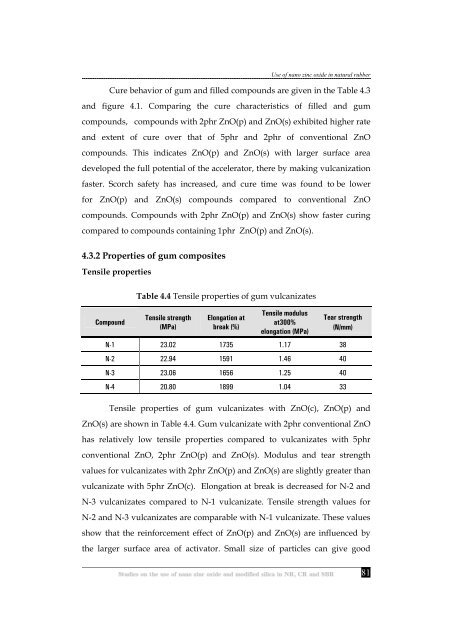

Table 4.4 Tensile properties <strong>of</strong> gum vulcanizates<br />

Tensile strength<br />

(MPa)<br />

El<strong>on</strong>gati<strong>on</strong> at<br />

break (%)<br />

Tensile modulus<br />

at300%<br />

el<strong>on</strong>gati<strong>on</strong> (MPa)<br />

Tear strength<br />

(N/mm)<br />

N-1 23.02 1735 1.17 38<br />

N-2 22.94 1591 1.46 40<br />

N-3 23.06 1656 1.25 40<br />

N-4 20.80 1899 1.04 33<br />

Tensile properties <strong>of</strong> gum vulcanizates with ZnO(c), ZnO(p) <strong>and</strong><br />

ZnO(s) are shown <strong>in</strong> Table 4.4. Gum vulcanizate with 2phr c<strong>on</strong>venti<strong>on</strong>al ZnO<br />

has relatively low tensile properties compared to vulcanizates with 5phr<br />

c<strong>on</strong>venti<strong>on</strong>al ZnO, 2phr ZnO(p) <strong>and</strong> ZnO(s). Modulus <strong>and</strong> tear strength<br />

values for vulcanizates with 2phr ZnO(p) <strong>and</strong> ZnO(s) are slightly greater than<br />

vulcanizate with 5phr ZnO(c). El<strong>on</strong>gati<strong>on</strong> at break is decreased for N-2 <strong>and</strong><br />

N-3 vulcanizates compared to N-1 vulcanizate. Tensile strength values for<br />

N-2 <strong>and</strong> N-3 vulcanizates are comparable with N-1 vulcanizate. These values<br />

show that <strong>the</strong> re<strong>in</strong>forcement effect <strong>of</strong> ZnO(p) <strong>and</strong> ZnO(s) are <strong>in</strong>fluenced by<br />

<strong>the</strong> larger surface area <strong>of</strong> activator. Small size <strong>of</strong> particles can give good<br />

81