Studies on the use of nano zinc oxide and modified silica in NR, CR ...

Studies on the use of nano zinc oxide and modified silica in NR, CR ...

Studies on the use of nano zinc oxide and modified silica in NR, CR ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Chapter 7<br />

phenylenediam<strong>in</strong>e], 6PPD [N-(1,3-dimethylbuty1)–N′-pheny1-p-<br />

phenylenediam<strong>in</strong>e], DPPD [N,N′-diphenyl-p-phenylenediam<strong>in</strong>e],<br />

naph<strong>the</strong>nic oil, diethylene glycol (DEG), cyclohexylbenzothiazyl<br />

sulfenamide (CBS), tetramethylthiuram disulfide (TMTD), sulphur.<br />

Preparati<strong>on</strong> <strong>of</strong> antioxidant <strong>modified</strong> precipitated <strong>silica</strong><br />

122<br />

Antioxidant (1phr) was mixed with precipitated <strong>silica</strong> (50phr) <strong>in</strong><br />

torque rheometer (Brabender plasticorder) at 50 rpm for above <strong>the</strong> melt<strong>in</strong>g<br />

temperature <strong>of</strong> antioxidant for 5 m<strong>in</strong>utes. Antioxidants <strong>use</strong>d <strong>in</strong> this study, to<br />

modify <strong>silica</strong> are IPPD, 6PPD <strong>and</strong> DPPD.<br />

Preparati<strong>on</strong> <strong>of</strong> composites<br />

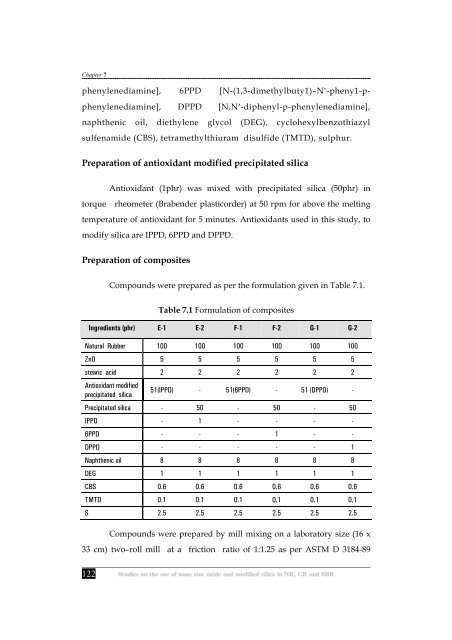

Compounds were prepared as per <strong>the</strong> formulati<strong>on</strong> given <strong>in</strong> Table 7.1.<br />

Table 7.1 Formulati<strong>on</strong> <strong>of</strong> composites<br />

Ingredients (phr) E-1 E-2 F-1 F-2 G-1 G-2<br />

Natural Rubber 100 100 100 100 100 100<br />

ZnO 5 5 5 5 5 5<br />

stearic acid 2 2 2 2 2 2<br />

Antioxidant <strong>modified</strong><br />

precipitated <strong>silica</strong><br />

51(IPPD) - 51(6PPD) - 51 (DPPD) -<br />

Precipitated <strong>silica</strong> - 50 - 50 - 50<br />

IPPD - 1 - - - -<br />

6PPD - - - 1 - -<br />

DPPD - - - - - 1<br />

Naph<strong>the</strong>nic oil 8 8 8 8 8 8<br />

DEG 1 1 1 1 1 1<br />

CBS 0.6 0.6 0.6 0.6 0.6 0.6<br />

TMTD 0.1 0.1 0.1 0.1 0.1 0.1<br />

S 2.5 2.5 2.5 2.5 2.5 2.5<br />

Compounds were prepared by mill mix<strong>in</strong>g <strong>on</strong> a laboratory size (16 x<br />

33 cm) two–roll mill at a fricti<strong>on</strong> ratio <strong>of</strong> 1:1.25 as per ASTM D 3184-89