Studies on the use of nano zinc oxide and modified silica in NR, CR ...

Studies on the use of nano zinc oxide and modified silica in NR, CR ...

Studies on the use of nano zinc oxide and modified silica in NR, CR ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Thermal age<strong>in</strong>g studies<br />

Use <strong>of</strong> antioxidant <strong>modified</strong> precipitated <strong>silica</strong> <strong>in</strong> natural rubber,<br />

chloroprene rubber <strong>and</strong> styrene butadiene rubber<br />

Thermal age<strong>in</strong>g was carried out at temperature <strong>of</strong> 100°C for 48, 72 <strong>and</strong><br />

96 hrs as per ASTM D 573-1999.<br />

7.7 Results <strong>and</strong> discussi<strong>on</strong><br />

7.7.1: Cure characteristics<br />

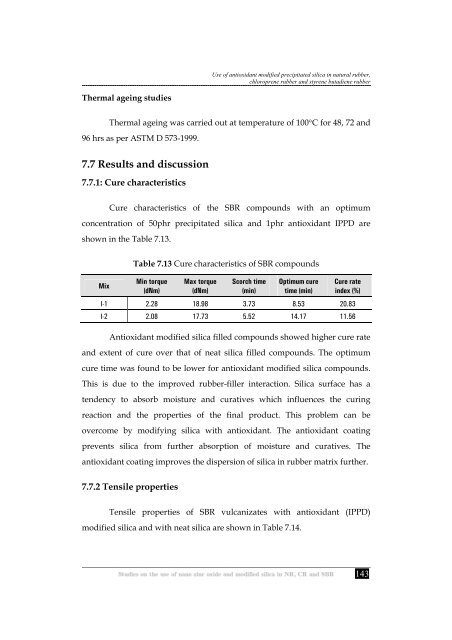

Cure characteristics <strong>of</strong> <strong>the</strong> SBR compounds with an optimum<br />

c<strong>on</strong>centrati<strong>on</strong> <strong>of</strong> 50phr precipitated <strong>silica</strong> <strong>and</strong> 1phr antioxidant IPPD are<br />

shown <strong>in</strong> <strong>the</strong> Table 7.13.<br />

Mix<br />

Table 7.13 Cure characteristics <strong>of</strong> SBR compounds<br />

M<strong>in</strong> torque<br />

(dNm)<br />

Max torque<br />

(dNm)<br />

Scorch time<br />

(m<strong>in</strong>)<br />

Optimum cure<br />

time (m<strong>in</strong>)<br />

Cure rate<br />

<strong>in</strong>dex (%)<br />

I-1 2.28 18.98 3.73 8.53 20.83<br />

I-2 2.08 17.73 5.52 14.17 11.56<br />

Antioxidant <strong>modified</strong> <strong>silica</strong> filled compounds showed higher cure rate<br />

<strong>and</strong> extent <strong>of</strong> cure over that <strong>of</strong> neat <strong>silica</strong> filled compounds. The optimum<br />

cure time was found to be lower for antioxidant <strong>modified</strong> <strong>silica</strong> compounds.<br />

This is due to <strong>the</strong> improved rubber-filler <strong>in</strong>teracti<strong>on</strong>. Silica surface has a<br />

tendency to absorb moisture <strong>and</strong> curatives which <strong>in</strong>fluences <strong>the</strong> cur<strong>in</strong>g<br />

reacti<strong>on</strong> <strong>and</strong> <strong>the</strong> properties <strong>of</strong> <strong>the</strong> f<strong>in</strong>al product. This problem can be<br />

overcome by modify<strong>in</strong>g <strong>silica</strong> with antioxidant. The antioxidant coat<strong>in</strong>g<br />

prevents <strong>silica</strong> from fur<strong>the</strong>r absorpti<strong>on</strong> <strong>of</strong> moisture <strong>and</strong> curatives. The<br />

antioxidant coat<strong>in</strong>g improves <strong>the</strong> dispersi<strong>on</strong> <strong>of</strong> <strong>silica</strong> <strong>in</strong> rubber matrix fur<strong>the</strong>r.<br />

7.7.2 Tensile properties<br />

Tensile properties <strong>of</strong> SBR vulcanizates with antioxidant (IPPD)<br />

<strong>modified</strong> <strong>silica</strong> <strong>and</strong> with neat <strong>silica</strong> are shown <strong>in</strong> Table 7.14.<br />

143