- Page 2:

Studies on the use

- Page 5 and 6:

WxvÄtÜtà|ÉÇ I hereby declare t

- Page 7 and 8:

My heartfelt thanks are also due to

- Page 9 and 10:

The use of prepared zinc oxides as

- Page 11 and 12:

2.2.10 Characterization techniques

- Page 13 and 14:

Part@ B 7.3.1 Characterization - su

- Page 15 and 16:

Introduction 1.1 Composites 1.1 Com

- Page 17 and 18:

Introduction of reinforcement and m

- Page 19 and 20:

Nanophase material: They are same a

- Page 21 and 22:

Introduction developed at Oxford Un

- Page 23 and 24:

Introduction Rubbers are broadly cl

- Page 25 and 26:

Introduction The polymers are prepa

- Page 27 and 28:

1.4.1 Zinc oxide Introduction Zinc

- Page 29 and 30:

Introduction and tinted rubber comp

- Page 31 and 32:

Pharmaceutical industry Introductio

- Page 33 and 34:

Introduction textiles contain ZnO,

- Page 35 and 36:

1.4.2a. Carbon blacks Introduction

- Page 37 and 38:

Introduction especially glass and c

- Page 39 and 40:

Introduction properties, filler cha

- Page 41 and 42:

Introduction coupling agent in sili

- Page 43 and 44:

Introduction amphiphilic di and tri

- Page 45 and 46:

Introduction It has been reported t

- Page 47 and 48:

Introduction The external manifesta

- Page 49 and 50:

Introduction concern for a clean en

- Page 51 and 52:

12. C.R.Martin, Chem. Mater, 1996,

- Page 53 and 54:

41. E.J.Stewart, J.Elastomers plast

- Page 55 and 56:

Introduction 69. J.B. Donnet (Ed),

- Page 57 and 58:

Introduction 100. C.T.Kresge, M.E.L

- Page 59 and 60:

Introduction 129. E.R.Ericsson, R.A

- Page 61 and 62:

Chapter 2 47 In a particular experi

- Page 63 and 64:

Chapter 2 Stearic acid (co-activato

- Page 65 and 66:

Chapter 2 roll with mill opening at

- Page 67 and 68:

Chapter 2 were carried out at a cro

- Page 69 and 70:

Chapter 2 2.2.4 Strain-sweep studie

- Page 71 and 72:

Chapter 2 2.2.6 Bound rubber conten

- Page 73 and 74:

Chapter 2 Surface area 59 Surface a

- Page 75 and 76:

Preparation and characterization of

- Page 77 and 78:

3.2.2 Method I- Precipitation metho

- Page 79 and 80:

Energy dispersive X-ray spectrometr

- Page 81 and 82:

Preparation and characterization of

- Page 83 and 84:

Preparation and characterization of

- Page 85 and 86:

3.4.9 Differential scanning calorim

- Page 87 and 88:

3.6 References Preparation and char

- Page 89 and 90:

Use of nano zinc oxide in natural r

- Page 91 and 92:

Use of nano zinc oxide in natural r

- Page 93 and 94:

Use of nano zinc oxide in natural r

- Page 95 and 96:

Use of nano zinc oxide in natural r

- Page 97 and 98:

Use of nano zinc oxide in natural r

- Page 99 and 100:

Use of nano zinc oxide in natural r

- Page 101 and 102:

Tear Strength (N/mm) 120 100 80 60

- Page 103 and 104:

4.5 References Use of nano zinc oxi

- Page 105 and 106:

Chapter 5 oil resistance to oil swe

- Page 107 and 108:

Chapter 5 93 Ingredient phr Table 5

- Page 109 and 110:

Chapter 5 95 Torque (dNm) 6.5 6.0 5

- Page 111 and 112:

Chapter 5 97 Other technological pr

- Page 113 and 114:

Chapter 5 99 Table 5.8 Reinforcing

- Page 115 and 116:

Chapter 5 101 Hours Table 5.11 Agei

- Page 117 and 118:

Chapter 5 5.5 References 103 1. D.C

- Page 119 and 120:

Chapter 6 105 Fatty acids as co-act

- Page 121 and 122:

Chapter 6 107 Physical properties s

- Page 123 and 124:

Chapter 6 The cure rate index of gu

- Page 125 and 126:

Chapter 6 show better mechanical pr

- Page 127 and 128:

Chapter 6 113 Table 6.6 Reinforcing

- Page 129 and 130: Chapter 6 115 Tensile modulus (Mpa)

- Page 131 and 132: Chapter 6 6.4 Conclusions 117 1. Gu

- Page 133 and 134: Use of antioxidant modified precipi

- Page 135 and 136: Use of antioxidant modified precipi

- Page 137 and 138: Use of antioxidant modified precipi

- Page 139 and 140: Mix Use of antioxidant modified pre

- Page 141 and 142: Use of antioxidant modified precipi

- Page 143 and 144: Crosslink density Use of antioxidan

- Page 145 and 146: Use of antioxidant modified precipi

- Page 147 and 148: Use of antioxidant modified precipi

- Page 149 and 150: Use of antioxidant modified precipi

- Page 151 and 152: Part@ B Use of antioxidant modified

- Page 153 and 154: Use of antioxidant modified precipi

- Page 155 and 156: Use of antioxidant modified precipi

- Page 157 and 158: Thermal ageing studies Use of antio

- Page 159 and 160: Use of antioxidant modified precipi

- Page 161 and 162: 7.9 References Use of antioxidant m

- Page 163 and 164: Products from rice husk as filler i

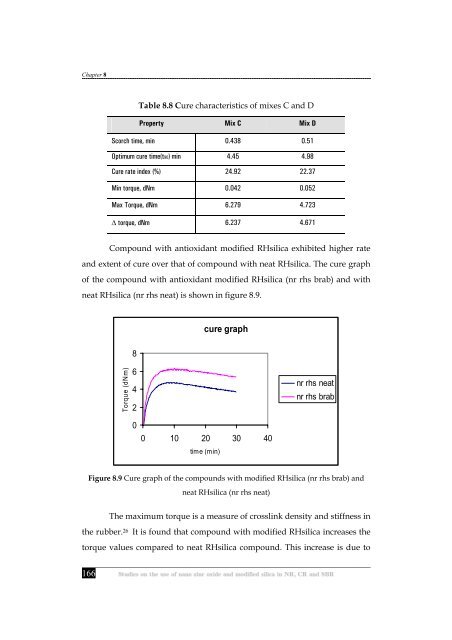

- Page 165 and 166: Products from rice husk as filler i

- Page 167 and 168: Rubber compounding Products from ri

- Page 169 and 170: Soxhlet extraction Products from ri

- Page 171 and 172: Products from rice husk as filler i

- Page 173 and 174: 8.3.4 Bound rubber content Products

- Page 175 and 176: Products from rice husk as filler i

- Page 177 and 178: Products from rice husk as filler i

- Page 179: Products from rice husk as filler i

- Page 183 and 184: . Hardness (Shore A ) 70 60 50 40 3

- Page 185 and 186: 8.8 References 1. V.M.H. Govindaro

- Page 187 and 188: Summary and Conclusions Polymers ar

- Page 189 and 190: Summary and Conclusion compounds an

- Page 191 and 192: ASTM : American Society for Testing

- Page 193 and 194: A. International/National journals

- Page 195: P.M.SABURA BEGUM Senior Scale Lectu