Studies on the use of nano zinc oxide and modified silica in NR, CR ...

Studies on the use of nano zinc oxide and modified silica in NR, CR ...

Studies on the use of nano zinc oxide and modified silica in NR, CR ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

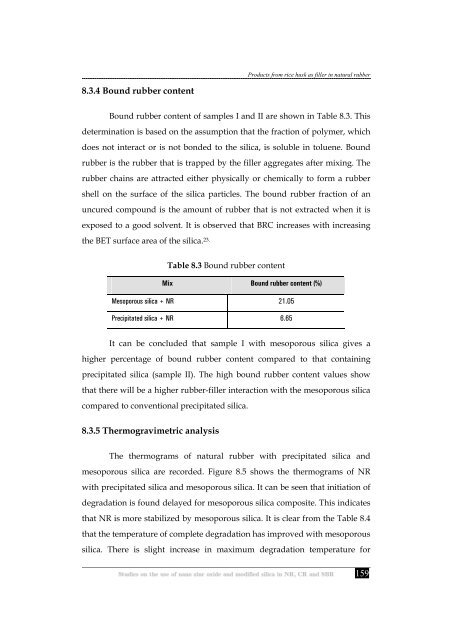

8.3.4 Bound rubber c<strong>on</strong>tent<br />

Products from rice husk as filler <strong>in</strong> natural rubber<br />

Bound rubber c<strong>on</strong>tent <strong>of</strong> samples I <strong>and</strong> II are shown <strong>in</strong> Table 8.3. This<br />

determ<strong>in</strong>ati<strong>on</strong> is based <strong>on</strong> <strong>the</strong> assumpti<strong>on</strong> that <strong>the</strong> fracti<strong>on</strong> <strong>of</strong> polymer, which<br />

does not <strong>in</strong>teract or is not b<strong>on</strong>ded to <strong>the</strong> <strong>silica</strong>, is soluble <strong>in</strong> toluene. Bound<br />

rubber is <strong>the</strong> rubber that is trapped by <strong>the</strong> filler aggregates after mix<strong>in</strong>g. The<br />

rubber cha<strong>in</strong>s are attracted ei<strong>the</strong>r physically or chemically to form a rubber<br />

shell <strong>on</strong> <strong>the</strong> surface <strong>of</strong> <strong>the</strong> <strong>silica</strong> particles. The bound rubber fracti<strong>on</strong> <strong>of</strong> an<br />

uncured compound is <strong>the</strong> amount <strong>of</strong> rubber that is not extracted when it is<br />

exposed to a good solvent. It is observed that BRC <strong>in</strong>creases with <strong>in</strong>creas<strong>in</strong>g<br />

<strong>the</strong> BET surface area <strong>of</strong> <strong>the</strong> <strong>silica</strong>. 23.<br />

Table 8.3 Bound rubber c<strong>on</strong>tent<br />

Mix Bound rubber c<strong>on</strong>tent (%)<br />

Mesoporous <strong>silica</strong> + <strong>NR</strong> 21.05<br />

Precipitated <strong>silica</strong> + <strong>NR</strong> 6.65<br />

It can be c<strong>on</strong>cluded that sample I with mesoporous <strong>silica</strong> gives a<br />

higher percentage <strong>of</strong> bound rubber c<strong>on</strong>tent compared to that c<strong>on</strong>ta<strong>in</strong><strong>in</strong>g<br />

precipitated <strong>silica</strong> (sample II). The high bound rubber c<strong>on</strong>tent values show<br />

that <strong>the</strong>re will be a higher rubber-filler <strong>in</strong>teracti<strong>on</strong> with <strong>the</strong> mesoporous <strong>silica</strong><br />

compared to c<strong>on</strong>venti<strong>on</strong>al precipitated <strong>silica</strong>.<br />

8.3.5 Thermogravimetric analysis<br />

The <strong>the</strong>rmograms <strong>of</strong> natural rubber with precipitated <strong>silica</strong> <strong>and</strong><br />

mesoporous <strong>silica</strong> are recorded. Figure 8.5 shows <strong>the</strong> <strong>the</strong>rmograms <strong>of</strong> <strong>NR</strong><br />

with precipitated <strong>silica</strong> <strong>and</strong> mesoporous <strong>silica</strong>. It can be seen that <strong>in</strong>itiati<strong>on</strong> <strong>of</strong><br />

degradati<strong>on</strong> is found delayed for mesoporous <strong>silica</strong> composite. This <strong>in</strong>dicates<br />

that <strong>NR</strong> is more stabilized by mesoporous <strong>silica</strong>. It is clear from <strong>the</strong> Table 8.4<br />

that <strong>the</strong> temperature <strong>of</strong> complete degradati<strong>on</strong> has improved with mesoporous<br />

<strong>silica</strong>. There is slight <strong>in</strong>crease <strong>in</strong> maximum degradati<strong>on</strong> temperature for<br />

159