Studies on the use of nano zinc oxide and modified silica in NR, CR ...

Studies on the use of nano zinc oxide and modified silica in NR, CR ...

Studies on the use of nano zinc oxide and modified silica in NR, CR ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Chapter 7<br />

142<br />

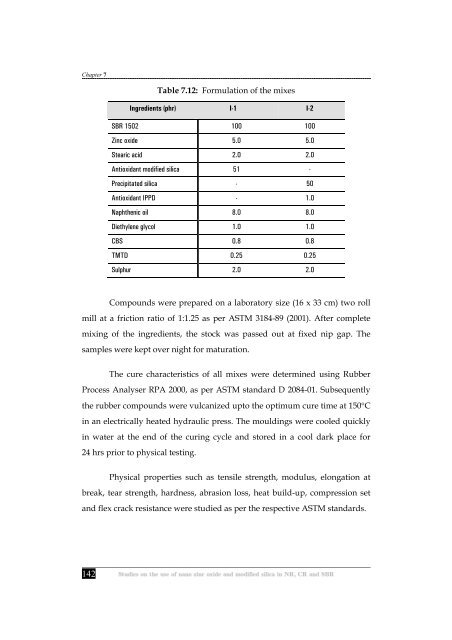

Table 7.12: Formulati<strong>on</strong> <strong>of</strong> <strong>the</strong> mixes<br />

Ingredients (phr) I-1 I-2<br />

SBR 1502 100 100<br />

Z<strong>in</strong>c <strong>oxide</strong> 5.0 5.0<br />

Stearic acid 2.0 2.0<br />

Antioxidant <strong>modified</strong> <strong>silica</strong> 51 -<br />

Precipitated <strong>silica</strong> - 50<br />

Antioxidant IPPD - 1.0<br />

Naph<strong>the</strong>nic oil 8.0 8.0<br />

Diethylene glycol 1.0 1.0<br />

CBS 0.8 0.8<br />

TMTD 0.25 0.25<br />

Sulphur 2.0 2.0<br />

Compounds were prepared <strong>on</strong> a laboratory size (16 x 33 cm) two roll<br />

mill at a fricti<strong>on</strong> ratio <strong>of</strong> 1:1.25 as per ASTM 3184-89 (2001). After complete<br />

mix<strong>in</strong>g <strong>of</strong> <strong>the</strong> <strong>in</strong>gredients, <strong>the</strong> stock was passed out at fixed nip gap. The<br />

samples were kept over night for maturati<strong>on</strong>.<br />

The cure characteristics <strong>of</strong> all mixes were determ<strong>in</strong>ed us<strong>in</strong>g Rubber<br />

Process Analyser RPA 2000, as per ASTM st<strong>and</strong>ard D 2084-01. Subsequently<br />

<strong>the</strong> rubber compounds were vulcanized upto <strong>the</strong> optimum cure time at 150°C<br />

<strong>in</strong> an electrically heated hydraulic press. The mould<strong>in</strong>gs were cooled quickly<br />

<strong>in</strong> water at <strong>the</strong> end <strong>of</strong> <strong>the</strong> cur<strong>in</strong>g cycle <strong>and</strong> stored <strong>in</strong> a cool dark place for<br />

24 hrs prior to physical test<strong>in</strong>g.<br />

Physical properties such as tensile strength, modulus, el<strong>on</strong>gati<strong>on</strong> at<br />

break, tear strength, hardness, abrasi<strong>on</strong> loss, heat build-up, compressi<strong>on</strong> set<br />

<strong>and</strong> flex crack resistance were studied as per <strong>the</strong> respective ASTM st<strong>and</strong>ards.