Studies on the use of nano zinc oxide and modified silica in NR, CR ...

Studies on the use of nano zinc oxide and modified silica in NR, CR ...

Studies on the use of nano zinc oxide and modified silica in NR, CR ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Chapter 7<br />

Test<strong>in</strong>g<br />

138<br />

The cure characteristics <strong>of</strong> all mixes were determ<strong>in</strong>ed us<strong>in</strong>g Rubber<br />

Process Analyzer RPA 2000, as per ASTM st<strong>and</strong>ard D 2084-01. Subsequently<br />

<strong>the</strong> rubber compounds were vulcanized upto <strong>the</strong> optimum cure time at 150°C<br />

<strong>in</strong> an electrically heated hydraulic press. The mould<strong>in</strong>gs were cooled quickly<br />

<strong>in</strong> water at <strong>the</strong> end <strong>of</strong> <strong>the</strong> cur<strong>in</strong>g cycle <strong>and</strong> stored <strong>in</strong> a cool dark place for<br />

24 hrs prior to physical test<strong>in</strong>g.<br />

Physical properties such as tensile strength, modulus, el<strong>on</strong>gati<strong>on</strong> at<br />

break, tear strength, hardness, abrasi<strong>on</strong> loss, heat build-up, compressi<strong>on</strong> set,<br />

<strong>and</strong> flex resistance were studied as per <strong>the</strong> respective ASTM st<strong>and</strong>ards.<br />

Thermal age<strong>in</strong>g studies<br />

Thermal age<strong>in</strong>g was carried out at temperature <strong>of</strong> 100°C for 48 hrs,<br />

72 hrs <strong>and</strong> 96 hrs as per <strong>the</strong> ASTM D 573-1999.<br />

7.5 Results <strong>and</strong> discussi<strong>on</strong><br />

7.5.1 Cure characteristics<br />

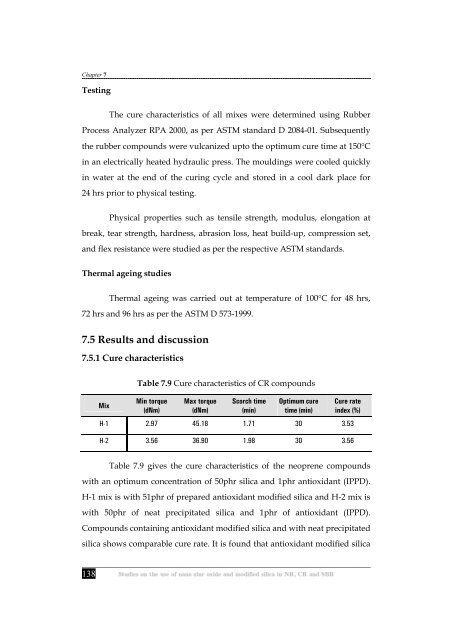

Mix<br />

Table 7.9 Cure characteristics <strong>of</strong> <strong>CR</strong> compounds<br />

M<strong>in</strong> torque<br />

(dNm)<br />

Max torque<br />

(dNm)<br />

Scorch time<br />

(m<strong>in</strong>)<br />

Optimum cure<br />

time (m<strong>in</strong>)<br />

Cure rate<br />

<strong>in</strong>dex (%)<br />

H-1 2.97 45.18 1.71 30 3.53<br />

H-2 3.56 36.90 1.98 30 3.56<br />

Table 7.9 gives <strong>the</strong> cure characteristics <strong>of</strong> <strong>the</strong> neoprene compounds<br />

with an optimum c<strong>on</strong>centrati<strong>on</strong> <strong>of</strong> 50phr <strong>silica</strong> <strong>and</strong> 1phr antioxidant (IPPD).<br />

H-1 mix is with 51phr <strong>of</strong> prepared antioxidant <strong>modified</strong> <strong>silica</strong> <strong>and</strong> H-2 mix is<br />

with 50phr <strong>of</strong> neat precipitated <strong>silica</strong> <strong>and</strong> 1phr <strong>of</strong> antioxidant (IPPD).<br />

Compounds c<strong>on</strong>ta<strong>in</strong><strong>in</strong>g antioxidant <strong>modified</strong> <strong>silica</strong> <strong>and</strong> with neat precipitated<br />

<strong>silica</strong> shows comparable cure rate. It is found that antioxidant <strong>modified</strong> <strong>silica</strong>