Solar Energy Perspectives - IEA

Solar Energy Perspectives - IEA

Solar Energy Perspectives - IEA

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

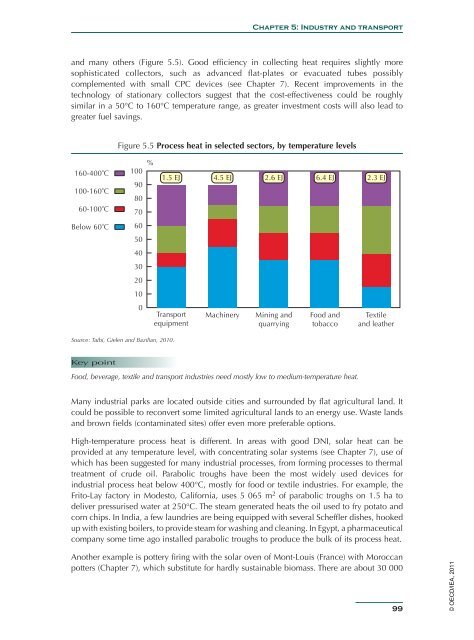

Chapter 5: Industry and transport<br />

and many others (Figure 5.5). Good efficiency in collecting heat requires slightly more<br />

sophisticated collectors, such as advanced flat-plates or evacuated tubes possibly<br />

complemented with small CPC devices (see Chapter 7). Recent improvements in the<br />

technology of stationary collectors suggest that the cost-effectiveness could be roughly<br />

similar in a 50°C to 160°C temperature range, as greater investment costs will also lead to<br />

greater fuel savings.<br />

Figure 5.5 Process heat in selected sectors, by temperature levels<br />

160-400 o C<br />

100-160 o C<br />

60-100 o<br />

C<br />

Below 60 o C<br />

100<br />

90<br />

80<br />

70<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

0<br />

%<br />

1.5 EJ 4.5 EJ 2.6 EJ 6.4 EJ 2.3 EJ<br />

Transport<br />

equipment<br />

Machinery<br />

Mining and<br />

quarrying<br />

Food and<br />

tobacco<br />

Textile<br />

and leather<br />

Source: Taibi, Gielen and Bazilian, 2010.<br />

Key point<br />

Food, beverage, textile and transport industries need mostly low to medium-temperature heat.<br />

Many industrial parks are located outside cities and surrounded by flat agricultural land. It<br />

could be possible to reconvert some limited agricultural lands to an energy use. Waste lands<br />

and brown fields (contaminated sites) offer even more preferable options.<br />

High-temperature process heat is different. In areas with good DNI, solar heat can be<br />

provided at any temperature level, with concentrating solar systems (see Chapter 7), use of<br />

which has been suggested for many industrial processes, from forming processes to thermal<br />

treatment of crude oil. Parabolic troughs have been the most widely used devices for<br />

industrial process heat below 400°C, mostly for food or textile industries. For example, the<br />

Frito-Lay factory in Modesto, California, uses 5 065 m 2 of parabolic troughs on 1.5 ha to<br />

deliver pressurised water at 250°C. The steam generated heats the oil used to fry potato and<br />

corn chips. In India, a few laundries are being equipped with several Scheffler dishes, hooked<br />

up with existing boilers, to provide steam for washing and cleaning. In Egypt, a pharmaceutical<br />

company some time ago installed parabolic troughs to produce the bulk of its process heat.<br />

Another example is pottery firing with the solar oven of Mont-Louis (France) with Moroccan<br />

potters (Chapter 7), which substitute for hardly sustainable biomass. There are about 30 000<br />

99<br />

© OECD/<strong>IEA</strong>, 2011