Solar Energy Perspectives - IEA

Solar Energy Perspectives - IEA

Solar Energy Perspectives - IEA

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Solar</strong> <strong>Energy</strong> <strong>Perspectives</strong>: <strong>Solar</strong> photovoltaics<br />

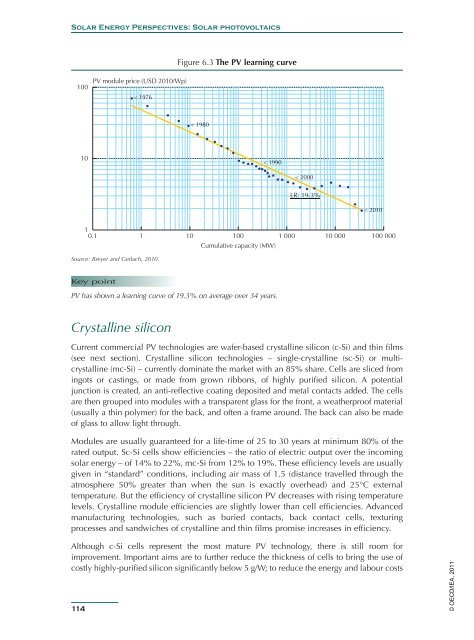

Figure 6.3 The PV learning curve<br />

100<br />

PV module price (USD 2010/Wp)<br />

< 1976<br />

< 1980<br />

10<br />

< 1990<br />

< 2000<br />

LR: 19.3%<br />

< 2010<br />

1<br />

0.1 1<br />

Source: Breyer and Gerlach, 2010.<br />

Key point<br />

10 100 1 000 10 000 100 000<br />

Cumulative capacity (MW)<br />

Figure 6.3<br />

PV has shown a learning curve of 19.3% on average over 34 years.<br />

Crystalline silicon<br />

Current commercial PV technologies are wafer-based crystalline silicon (c-Si) and thin films<br />

(see next section). Crystalline silicon technologies – single-crystalline (sc-Si) or multicrystalline<br />

(mc-Si) – currently dominate the market with an 85% share. Cells are sliced from<br />

ingots or castings, or made from grown ribbons, of highly purified silicon. A potential<br />

junction is created, an anti-reflective coating deposited and metal contacts added. The cells<br />

are then grouped into modules with a transparent glass for the front, a weatherproof material<br />

(usually a thin polymer) for the back, and often a frame around. The back can also be made<br />

of glass to allow light through.<br />

Modules are usually guaranteed for a life-time of 25 to 30 years at minimum 80% of the<br />

rated output. Sc-Si cells show efficiencies – the ratio of electric output over the incoming<br />

solar energy – of 14% to 22%, mc-Si from 12% to 19%. These efficiency levels are usually<br />

given in “standard” conditions, including air mass of 1.5 (distance travelled through the<br />

atmosphere 50% greater than when the sun is exactly overhead) and 25°C external<br />

temperature. But the efficiency of crystalline silicon PV decreases with rising temperature<br />

levels. Crystalline module efficiencies are slightly lower than cell efficiencies. Advanced<br />

manufacturing technologies, such as buried contacts, back contact cells, texturing<br />

processes and sandwiches of crystalline and thin films promise increases in efficiency.<br />

Although c-Si cells represent the most mature PV technology, there is still room for<br />

improvement. Important aims are to further reduce the thickness of cells to bring the use of<br />

costly highly-purified silicon significantly below 5 g/W; to reduce the energy and labour costs<br />

114<br />

© OECD/<strong>IEA</strong>, 2011