Solar Energy Perspectives - IEA

Solar Energy Perspectives - IEA

Solar Energy Perspectives - IEA

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Solar</strong> <strong>Energy</strong> <strong>Perspectives</strong>: <strong>Solar</strong> electricity<br />

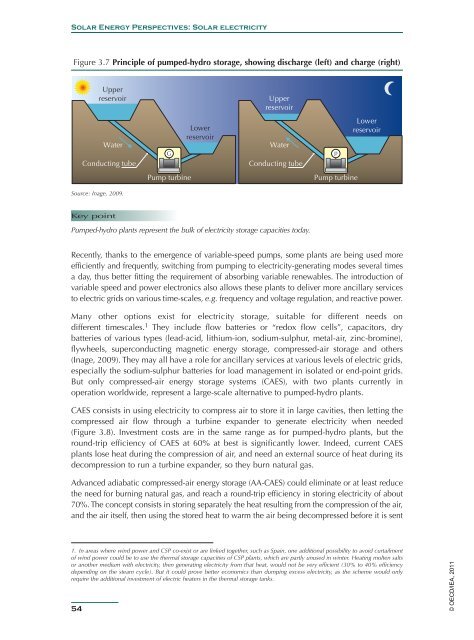

Figure 3.7 Principle of pumped-hydro storage, showing discharge (left) and charge (right)<br />

Upper<br />

reservoir<br />

Upper<br />

reservoir<br />

Water<br />

Conducting tube<br />

G<br />

Lower<br />

reservoir<br />

Water<br />

Conducting tube<br />

p<br />

Lower<br />

reservoir<br />

Pump turbine<br />

Pump turbine<br />

Source: Inage, 2009.<br />

Key point<br />

Pumped-hydro plants represent the bulk of electricity storage capacities today.<br />

Recently, thanks to the emergence of variable-speed pumps, some plants are being used more<br />

efficiently and frequently, switching from pumping to electricity-generating modes several times<br />

a day, thus better fitting the requirement of absorbing variable renewables. The introduction of<br />

variable speed and power electronics also allows these plants to deliver more ancillary services<br />

to electric grids on various time-scales, e.g. frequency and voltage regulation, and reactive power.<br />

Many other options exist for electricity storage, suitable for different needs on<br />

different timescales. 1 They include flow batteries or “redox flow cells”, capacitors, dry<br />

batteries of various types (lead-acid, lithium-ion, sodium-sulphur, metal-air, zinc-bromine),<br />

flywheels, superconducting magnetic energy storage, compressed-air storage and others<br />

(Inage, 2009). They may all have a role for ancillary services at various levels of electric grids,<br />

especially the sodium-sulphur batteries for load management in isolated or end-point grids.<br />

But only compressed-air energy storage systems (CAES), with two plants currently in<br />

operation worldwide, represent a large-scale alternative to pumped-hydro plants.<br />

CAES consists in using electricity to compress air to store it in large cavities, then letting the<br />

compressed air flow through a turbine expander to generate electricity when needed<br />

(Figure 3.8). Investment costs are in the same range as for pumped-hydro plants, but the<br />

round-trip efficiency of CAES at 60% at best is significantly lower. Indeed, current CAES<br />

plants lose heat during the compression of air, and need an external source of heat during its<br />

decompression to run a turbine expander, so they burn natural gas.<br />

Advanced adiabatic compressed-air energy storage (AA-CAES) could eliminate or at least reduce<br />

the need for burning natural gas, and reach a round-trip efficiency in storing electricity of about<br />

70%. The concept consists in storing separately the heat resulting from the compression of the air,<br />

and the air itself, then using the stored heat to warm the air being decompressed before it is sent<br />

1. In areas where wind power and CSP co-exist or are linked together, such as Spain, one additional possibility to avoid curtailment<br />

of wind power could be to use the thermal storage capacities of CSP plants, which are partly unused in winter. Heating molten salts<br />

or another medium with electricity, then generating electricity from that heat, would not be very efficient (30% to 40% efficiency<br />

depending on the steam cycle). But it could prove better economics than dumping excess electricity, as the scheme would only<br />

require the additional investment of electric heaters in the thermal storage tanks.<br />

54<br />

© OECD/<strong>IEA</strong>, 2011