Solar Energy Perspectives - IEA

Solar Energy Perspectives - IEA

Solar Energy Perspectives - IEA

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

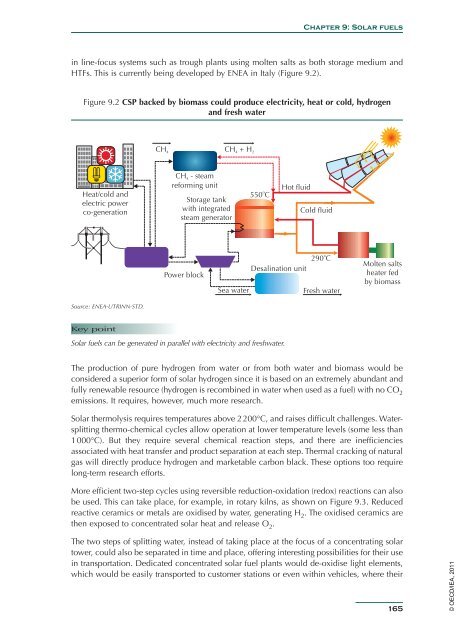

Chapter 9: <strong>Solar</strong> fuels<br />

in line-focus systems such as trough plants using molten salts as both storage medium and<br />

HTFs. This is currently being developed by ENEA in Italy (Figure 9.2).<br />

Figure 9.2 CSP backed by biomass could produce electricity, heat or cold, hydrogen<br />

and fresh water<br />

CH 4<br />

CH + H 4 2<br />

Heat/cold and<br />

electric power<br />

co-generation<br />

CH4<br />

- steam<br />

reforming unit<br />

Storage tank<br />

with integrated<br />

steam generator<br />

550 o C<br />

Hot fluid<br />

Cold fluid<br />

Power block<br />

290 o C<br />

Desalination unit<br />

Sea water<br />

Fresh water<br />

Molten salts<br />

heater fed<br />

by biomass<br />

Source: ENEA-UTRINN-STD.<br />

Key point<br />

<strong>Solar</strong> fuels can be generated in parallel with electricity and freshwater.<br />

The production of pure hydrogen from water or from both water and biomass would be<br />

considered a superior form of solar hydrogen since it is based on an extremely abundant and<br />

fully renewable resource (hydrogen is recombined in water when used as a fuel) with no CO 2<br />

emissions. It requires, however, much more research.<br />

<strong>Solar</strong> thermolysis requires temperatures above 2 200°C, and raises difficult challenges. Watersplitting<br />

thermo-chemical cycles allow operation at lower temperature levels (some less than<br />

1 000°C). But they require several chemical reaction steps, and there are inefficiencies<br />

associated with heat transfer and product separation at each step. Thermal cracking of natural<br />

gas will directly produce hydrogen and marketable carbon black. These options too require<br />

long-term research efforts.<br />

More efficient two-step cycles using reversible reduction-oxidation (redox) reactions can also<br />

be used. This can take place, for example, in rotary kilns, as shown on Figure 9.3. Reduced<br />

reactive ceramics or metals are oxidised by water, generating H 2 . The oxidised ceramics are<br />

then exposed to concentrated solar heat and release O 2 .<br />

The two steps of splitting water, instead of taking place at the focus of a concentrating solar<br />

tower, could also be separated in time and place, offering interesting possibilities for their use<br />

in transportation. Dedicated concentrated solar fuel plants would de-oxidise light elements,<br />

which would be easily transported to customer stations or even within vehicles, where their<br />

165<br />

© OECD/<strong>IEA</strong>, 2011