Solar Energy Perspectives - IEA

Solar Energy Perspectives - IEA

Solar Energy Perspectives - IEA

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Solar</strong> <strong>Energy</strong> <strong>Perspectives</strong>: <strong>Solar</strong> thermal electricity<br />

Most first-generation plants have little or no thermal storage and rely on combustible fuel as<br />

a firm capacity back-up. CSP plants in Spain derive 12% to 15% of their annual electricity<br />

generation from burning natural gas. More than 60% of the Spanish plants already built or under<br />

construction, however, have significant thermal storage capacities, based on two-tank molten-salt<br />

systems, with a difference of temperatures between the hot tank and the cold one of about 100°C.<br />

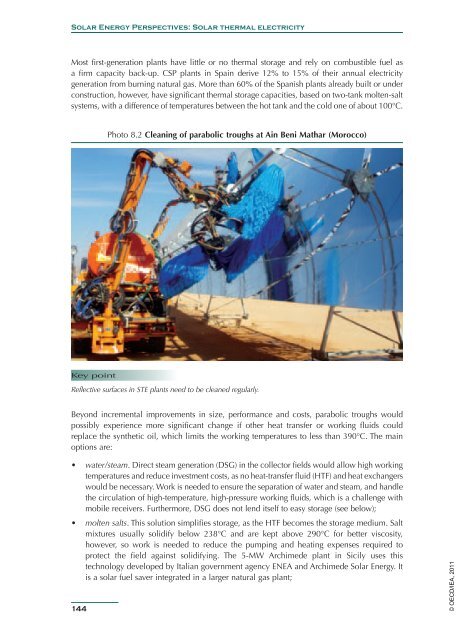

Photo 8.2 Cleaning of parabolic troughs at Ain Beni Mathar (Morocco)<br />

Key point<br />

Reflective surfaces in STE plants need to be cleaned regularly.<br />

Beyond incremental improvements in size, performance and costs, parabolic troughs would<br />

possibly experience more significant change if other heat transfer or working fluids could<br />

replace the synthetic oil, which limits the working temperatures to less than 390°C. The main<br />

options are:<br />

• water/steam. Direct steam generation (DSG) in the collector fields would allow high working<br />

temperatures and reduce investment costs, as no heat-transfer fluid (HTF) and heat exchangers<br />

would be necessary. Work is needed to ensure the separation of water and steam, and handle<br />

the circulation of high-temperature, high-pressure working fluids, which is a challenge with<br />

mobile receivers. Furthermore, DSG does not lend itself to easy storage (see below);<br />

• molten salts. This solution simplifies storage, as the HTF becomes the storage medium. Salt<br />

mixtures usually solidify below 238°C and are kept above 290°C for better viscosity,<br />

however, so work is needed to reduce the pumping and heating expenses required to<br />

protect the field against solidifying. The 5-MW Archimede plant in Sicily uses this<br />

technology developed by Italian government agency ENEA and Archimede <strong>Solar</strong> <strong>Energy</strong>. It<br />

is a solar fuel saver integrated in a larger natural gas plant;<br />

144<br />

© OECD/<strong>IEA</strong>, 2011