Solar Energy Perspectives - IEA

Solar Energy Perspectives - IEA

Solar Energy Perspectives - IEA

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Chapter 7: <strong>Solar</strong> heat<br />

incoming radiation is much shorter-wave. Glass has the property of being relatively opaque<br />

to long-wave radiation – radiant heat – while letting the incoming light through.<br />

<strong>Solar</strong> radiation enters the collector through the transparent cover and reaches the absorber,<br />

where the absorbed radiation is converted to thermal energy. A good thermal conductivity<br />

is needed to transfer the collected heat from the absorber sheet to the absorber pipes,<br />

where the heat is transferred to a fluid. Usually a water/glycol mixture with anticorrosion<br />

additives is used as the heat-carrying fluid. The fluid also protects the collector from frost<br />

damage.<br />

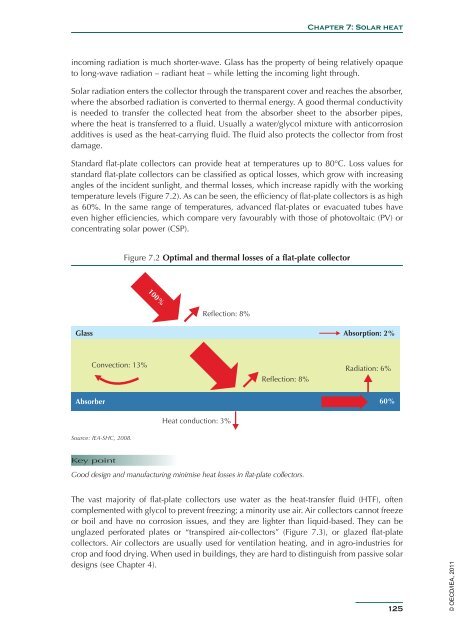

Standard flat-plate collectors can provide heat at temperatures up to 80°C. Loss values for<br />

standard flat-plate collectors can be classified as optical losses, which grow with increasing<br />

angles of the incident sunlight, and thermal losses, which increase rapidly with the working<br />

temperature levels (Figure 7.2). As can be seen, the efficiency of flat-plate collectors is as high<br />

as 60%. In the same range of temperatures, advanced flat-plates or evacuated tubes have<br />

even higher efficiencies, which compare very favourably with those of photovoltaic (PV) or<br />

concentrating solar power (CSP).<br />

Figure 7.2 Optimal and thermal losses of a flat-plate collector<br />

100%<br />

Reflection: 8%<br />

Glass Absorption: 2%<br />

Convection: 13%<br />

Reflection: 8%<br />

Radiation: 6%<br />

Absorber 60%<br />

Heat conduction: 3%<br />

Source: <strong>IEA</strong>-SHC, 2008.<br />

Key point<br />

Good design and manufacturing minimise heat losses in flat-plate collectors.<br />

The vast majority of flat-plate collectors use water as the heat-transfer fluid (HTF), often<br />

complemented with glycol to prevent freezing; a minority use air. Air collectors cannot freeze<br />

or boil and have no corrosion issues, and they are lighter than liquid-based. They can be<br />

unglazed perforated plates or “transpired air-collectors” (Figure 7.3), or glazed flat-plate<br />

collectors. Air collectors are usually used for ventilation heating, and in agro-industries for<br />

crop and food drying. When used in buildings, they are hard to distinguish from passive solar<br />

designs (see Chapter 4).<br />

125<br />

© OECD/<strong>IEA</strong>, 2011