- Page 1 and 2:

GSR60099500-36160-01E

- Page 3:

HOW TO USE THIS MANUALTO LOCATE WHA

- Page 6 and 7:

MMAL-CodeMaxMILMinNNOXOOHCOPSPPCVRS

- Page 8:

GENERAL INFORMATION 1-1GENERAL INFO

- Page 11 and 12:

1-4 GENERAL INFORMATIONSUZUKI GSR60

- Page 13 and 14:

1-6 GENERAL INFORMATIONENGINE COOLA

- Page 15 and 16:

1-8 GENERAL INFORMATIONINFORMATION

- Page 17 and 18:

1-10 GENERAL INFORMATIONCHASSISFron

- Page 19 and 20:

2-2 PERIODIC MAINTENANCEPERIODIC MA

- Page 21 and 22:

2-4 PERIODIC MAINTENANCEMAINTENANCE

- Page 23 and 24:

2-6 PERIODIC MAINTENANCESPARK PLUG

- Page 25 and 26:

2-8 PERIODIC MAINTENANCE• Remove

- Page 27 and 28:

2-10 PERIODIC MAINTENANCENOTE:* Be

- Page 29 and 30:

2-12 PERIODIC MAINTENANCE(EXHAUST S

- Page 31 and 32:

2-14 PERIODIC MAINTENANCEOIL FILTER

- Page 33 and 34:

2-16 PERIODIC MAINTENANCECLUTCHInsp

- Page 35 and 36:

2-18 PERIODIC MAINTENANCEAIR BLEEDI

- Page 37 and 38: 2-20 PERIODIC MAINTENANCE• Count

- Page 39 and 40: 2-22 PERIODIC MAINTENANCEBRAKE(BRAK

- Page 41 and 42: 2-24 PERIODIC MAINTENANCEBRAKE LIGH

- Page 43 and 44: 2-26 PERIODIC MAINTENANCETIRESInspe

- Page 45 and 46: 2-28 PERIODIC MAINTENANCEEXHAUST PI

- Page 47 and 48: 2-30 PERIODIC MAINTENANCE

- Page 49 and 50: 2-32 PERIODIC MAINTENANCEOIL PRESSU

- Page 51 and 52: 2-34 PERIODIC MAINTENANCEData at 3

- Page 53 and 54: ENGINE 3-1ENGINECONTENTSENGINE COMP

- Page 55 and 56: ENGINE 3-3ENGINE REMOVAL AND INSTAL

- Page 57 and 58: ENGINE 3-5• Remove the front engi

- Page 59 and 60: ENGINE 3-7ENGINE SPROCKET AND GEAR

- Page 61 and 62: ENGINE 3-9• Remove the engine mou

- Page 63 and 64: ENGINE 3-11• Tighten all engine m

- Page 65 and 66: ENGINE 3-13• Replace the exhaust

- Page 67 and 68: ENGINE 3-15CAMSHAFTS• Remove the

- Page 69 and 70: ENGINE 3-17CLUTCH• Remove the clu

- Page 71 and 72: ENGINE 3-19• Remove the thrust wa

- Page 73 and 74: ENGINE 3-21• Remove the starter c

- Page 75 and 76: ENGINE 3-23GEAR POSITION SWITCH•

- Page 77 and 78: ENGINE 3-25MIDDLE CRANKCASE• Remo

- Page 79 and 80: ENGINE 3-27ENGINE COMPONENTS INSPEC

- Page 81 and 82: ENGINE 3-29CAMSHAFT JOURNAL WEAR•

- Page 83 and 84: ENGINE 3-31CAM CHAIN TENSIONERINSPE

- Page 85 and 86: ENGINE 3-33VALVE STEM RUNOUT• Sup

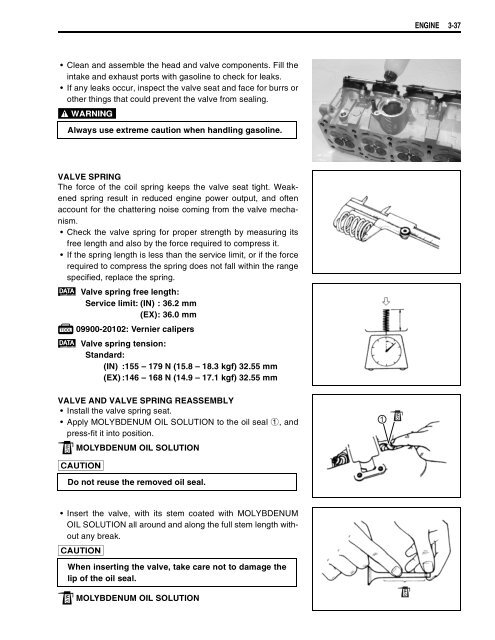

- Page 87: ENGINE 3-35• Cool down the new va

- Page 91 and 92: ENGINE 3-39INTAKE PIPE• Remove th

- Page 93 and 94: ENGINE 3-41CLUTCH BEARING INSPECTIO

- Page 95 and 96: ENGINE 3-43WATER PUMPDISASSEMBLY/IN

- Page 97 and 98: ENGINE 3-45TRANSMISSIONDISASSEMBLYD

- Page 99 and 100: ENGINE 3-47TRANSMISSION PARTS LOCAT

- Page 101 and 102: ENGINE 3-49PISTON AND PISTON RINGPI

- Page 103 and 104: ENGINE 3-51CRANKCASEGEARSHIFT FORK

- Page 105 and 106: ENGINE 3-53• Remove the oil seal

- Page 107 and 108: ENGINE 3-55OIL JETRemoval• Remove

- Page 109 and 110: ENGINE 3-57• Remove the water jac

- Page 111 and 112: ENGINE 3-59CONROD BIG END SIDE CLEA

- Page 113 and 114: ENGINE 3-61 Crank pin O.D.CodeO.D.

- Page 115 and 116: ENGINE 3-63• Check the correspond

- Page 117 and 118: ENGINE 3-65CRANKSHAFT THRUST BEARIN

- Page 119 and 120: ENGINE 3-67ENGINE REASSEMBLY• Rea

- Page 121 and 122: ENGINE 3-69• Install the pistons

- Page 123 and 124: ENGINE 3-71• Insert the right and

- Page 125 and 126: ENGINE 3-73• Install the regulato

- Page 127 and 128: ENGINE 3-75• Apply SUZUKI BOND to

- Page 129 and 130: ENGINE 3-77OIL STRAINER• Install

- Page 131 and 132: ENGINE 3-79CRANKCASE BREATHER COVER

- Page 133 and 134: ENGINE 3-81• Apply SUZUKI BOND to

- Page 135 and 136: ENGINE 3-83CAM CHAIN DRIVE SPROCKET

- Page 137 and 138: ENGINE 3-85• Install the starter

- Page 139 and 140:

ENGINE 3-87OIL PUMP• Install the

- Page 141 and 142:

ENGINE 3-89• Lock the clutch slee

- Page 143 and 144:

ENGINE 3-91• Install the pressure

- Page 145 and 146:

ENGINE 3-93• Apply SUZUKI SUPER G

- Page 147 and 148:

ENGINE 3-95• Pull the cam chain l

- Page 149 and 150:

ENGINE 3-97• Tighten the camshaft

- Page 151 and 152:

ENGINE 3-99A Cam chain tension adju

- Page 153 and 154:

ENGINE 3-101• Tighten the head co

- Page 155 and 156:

4-2 FI SYSTEM DIAGNOSISFI SYSTEM DI

- Page 157 and 158:

4-4 FI SYSTEM DIAGNOSIS• When con

- Page 159 and 160:

4-6 FI SYSTEM DIAGNOSISELECTRICAL C

- Page 161 and 162:

4-8 FI SYSTEM DIAGNOSISSHORT CIRCUI

- Page 163 and 164:

4-10 FI SYSTEM DIAGNOSISFI SYSTEM T

- Page 165 and 166:

4-12 FI SYSTEM DIAGNOSISFI SYSTEM P

- Page 167 and 168:

4-14 FI SYSTEM DIAGNOSISFI SYSTEM W

- Page 169 and 170:

4-16 FI SYSTEM DIAGNOSISSELF-DIAGNO

- Page 171 and 172:

4-18 FI SYSTEM DIAGNOSISCODE MALFUN

- Page 173 and 174:

4-20 FI SYSTEM DIAGNOSISFAIL-SAFE F

- Page 175 and 176:

4-22 FI SYSTEM DIAGNOSISFI SYSTEM T

- Page 177 and 178:

4-24 FI SYSTEM DIAGNOSISSELF-DIAGNO

- Page 179 and 180:

4-26 FI SYSTEM DIAGNOSISUSE OF SDS

- Page 181 and 182:

4-28 FI SYSTEM DIAGNOSISMALFUNCTION

- Page 183 and 184:

4-30 FI SYSTEM DIAGNOSISDTC No.C29P

- Page 185 and 186:

4-32 FI SYSTEM DIAGNOSIS“C11” (

- Page 187 and 188:

4-34 FI SYSTEM DIAGNOSIS“C12” (

- Page 189 and 190:

4-36 FI SYSTEM DIAGNOSIS“C13” (

- Page 191 and 192:

4-38 FI SYSTEM DIAGNOSIS6) Disconne

- Page 193 and 194:

4-40 FI SYSTEM DIAGNOSISStep 31) Tu

- Page 195 and 196:

4-42 FI SYSTEM DIAGNOSIS“C14” (

- Page 197 and 198:

4-44 FI SYSTEM DIAGNOSISStep 1 (Whe

- Page 199 and 200:

4-46 FI SYSTEM DIAGNOSISAre the con

- Page 201 and 202:

4-48 FI SYSTEM DIAGNOSISStep 1 (Whe

- Page 203 and 204:

4-50 FI SYSTEM DIAGNOSISStep 21) Tu

- Page 205 and 206:

4-52 FI SYSTEM DIAGNOSISStep 1 (Whe

- Page 207 and 208:

4-54 FI SYSTEM DIAGNOSISStep 21) Tu

- Page 209 and 210:

4-56 FI SYSTEM DIAGNOSIS4) Disconne

- Page 211 and 212:

4-58 FI SYSTEM DIAGNOSIS7) Disconne

- Page 213 and 214:

4-60 FI SYSTEM DIAGNOSIS“C23” (

- Page 215 and 216:

4-62 FI SYSTEM DIAGNOSISStep 1 (Whe

- Page 217 and 218:

4-64 FI SYSTEM DIAGNOSIS“C28” (

- Page 219 and 220:

4-66 FI SYSTEM DIAGNOSISACTIVE CONT

- Page 221 and 222:

4-68 FI SYSTEM DIAGNOSIS STP sensor

- Page 223 and 224:

4-70 FI SYSTEM DIAGNOSISStep 21) Tu

- Page 225 and 226:

4-72 FI SYSTEM DIAGNOSIS“C31” (

- Page 227 and 228:

4-74 FI SYSTEM DIAGNOSIS“C32” (

- Page 229 and 230:

M4-76 FI SYSTEM DIAGNOSIS“C41”

- Page 231 and 232:

4-78 FI SYSTEM DIAGNOSIS“C42” (

- Page 233 and 234:

4-80 FI SYSTEM DIAGNOSIS6) Remove t

- Page 235 and 236:

4-82 FI SYSTEM DIAGNOSISStep 2 (Whe

- Page 237 and 238:

4-84 FI SYSTEM DIAGNOSISStep 21) Tu

- Page 239 and 240:

4-86 FI SYSTEM DIAGNOSISACTIVE CONT

- Page 241 and 242:

4-88 FI SYSTEM DIAGNOSISECT SENSOR

- Page 243 and 244:

4-90 FI SYSTEM DIAGNOSISHO2 SENSOR

- Page 245 and 246:

5-2 FUEL SYSTEM AND THROTTLE BODYFU

- Page 247 and 248:

5-4 FUEL SYSTEM AND THROTTLE BODYFU

- Page 249 and 250:

5-6 FUEL SYSTEM AND THROTTLE BODYFU

- Page 251 and 252:

5-8 FUEL SYSTEM AND THROTTLE BODYRE

- Page 253 and 254:

5-10 FUEL SYSTEM AND THROTTLE BODY

- Page 255 and 256:

5-12 FUEL SYSTEM AND THROTTLE BODYT

- Page 257:

5-14 FUEL SYSTEM AND THROTTLE BODY

- Page 260 and 261:

FUEL SYSTEM AND THROTTLE BODY 5-17T

- Page 262 and 263:

FUEL SYSTEM AND THROTTLE BODY 5-19T

- Page 264 and 265:

FUEL SYSTEM AND THROTTLE BODY 5-21F

- Page 266 and 267:

FUEL SYSTEM AND THROTTLE BODY 5-23

- Page 268 and 269:

FUEL SYSTEM AND THROTTLE BODY 5-25S

- Page 270 and 271:

6-2 EXHAUST SYSTEMPRECAUTIONS FOR E

- Page 272 and 273:

6-4 EXHAUST SYSTEM• Remove the mu

- Page 274 and 275:

COOLING AND LUBRICATION SYSTEM 7-1C

- Page 276 and 277:

COOLING AND LUBRICATION SYSTEM 7-3C

- Page 278 and 279:

COOLING AND LUBRICATION SYSTEM 7-5R

- Page 280 and 281:

COOLING AND LUBRICATION SYSTEM 7-7E

- Page 282 and 283:

COOLING AND LUBRICATION SYSTEM 7-9T

- Page 284 and 285:

COOLING AND LUBRICATION SYSTEM 7-11

- Page 286 and 287:

COOLING AND LUBRICATION SYSTEM 7-13

- Page 288 and 289:

COOLING AND LUBRICATION SYSTEM 7-15

- Page 290 and 291:

COOLING AND LUBRICATION SYSTEM 7-17

- Page 292 and 293:

COOLING AND LUBRICATION SYSTEM 7-19

- Page 294 and 295:

COOLING AND LUBRICATION SYSTEM 7-21

- Page 296 and 297:

8-2 CHASSISCHASSISCONTENTSREAR SUSP

- Page 298 and 299:

8-4 CHASSIS• Disconnect the turn

- Page 300 and 301:

8-6 CHASSISFRONT WHEELCONSTRUCTION1

- Page 302 and 303:

8-8 CHASSISINSPECTION AND DISASSEMB

- Page 304 and 305:

8-10 CHASSISREASSEMBLY AND INSTALLA

- Page 306 and 307:

8-12 CHASSISWHEELInstall the front

- Page 308 and 309:

8-14 CHASSISREMOVAL AND DISASSEMBLY

- Page 310 and 311:

8-16 CHASSIS• Remove the cylinder

- Page 312 and 313:

8-18 CHASSIS• Insert the inner tu

- Page 314 and 315:

8-20 CHASSISFRONT FORK CAP BOLT•

- Page 316 and 317:

8-22 CHASSISREMOVAL• Remove the f

- Page 318 and 319:

8-24 CHASSISREASSEMBLYReassemble th

- Page 320 and 321:

8-26 CHASSISSTEERING TENSION ADJUST

- Page 322 and 323:

8-28 CHASSISREMOVAL• Remove the f

- Page 324 and 325:

8-30 CHASSISAfter installing the ha

- Page 326 and 327:

8-32 CHASSISREMOVAL• Loosen the a

- Page 328 and 329:

8-34 CHASSISBEARINGSInspect the whe

- Page 330 and 331:

8-36 CHASSISBEARINGS• Apply SUZUK

- Page 332 and 333:

8-38 CHASSISBRAKE DISC• Apply THR

- Page 334 and 335:

8-40 CHASSISREMOVAL• Remove the u

- Page 336 and 337:

8-42 CHASSISSUSPENSION SETTINGAfter

- Page 338 and 339:

8-44 CHASSISREMOVAL• Remove the s

- Page 340 and 341:

8-46 CHASSISINSPECTION AND DISASSEM

- Page 342 and 343:

8-48 CHASSISPLATE• Inspect the pl

- Page 344 and 345:

8-50 CHASSISSWINGARM BEARING• Pre

- Page 346 and 347:

8-52 CHASSISSHOCK ABSORBER AND CUSH

- Page 348 and 349:

8-54 CHASSIS* This brake system is

- Page 350 and 351:

8-56 CHASSISCALIPER REMOVAL• Remo

- Page 352 and 353:

8-58 CHASSISPISTON SEAL• Install

- Page 354 and 355:

8-60 CHASSISMASTER CYLINDER REMOVAL

- Page 356 and 357:

8-62 CHASSISMASTER CYLINDER REASSEM

- Page 358 and 359:

8-64 CHASSISREAR BRAKECONSTRUCTION1

- Page 360 and 361:

8-66 CHASSIS• Install new brake p

- Page 362 and 363:

8-68 CHASSISCALIPER INSPECTIONBRAKE

- Page 364 and 365:

8-70 CHASSIS• Remove the front fo

- Page 366 and 367:

8-72 CHASSIS• Rout the rear brake

- Page 368 and 369:

8-74 CHASSISVALVE INSPECTION• Ins

- Page 370 and 371:

8-76 CHASSIS• In this condition,

- Page 372 and 373:

8-78 CHASSIS• Place the drive cha

- Page 374 and 375:

8-80 CHASSIS• Stake the joint pin

- Page 376 and 377:

9-2 ELECTRICAL SYSTEMELECTRICAL SYS

- Page 378 and 379:

9-4 ELECTRICAL SYSTEMSEMI-CONDUCTOR

- Page 380 and 381:

9-6 ELECTRICAL SYSTEMLOCATION OF EL

- Page 382 and 383:

9-8 ELECTRICAL SYSTEMCHARGING SYSTE

- Page 384 and 385:

9-10 ELECTRICAL SYSTEMREGULATED VOL

- Page 386 and 387:

9-12 ELECTRICAL SYSTEMSTARTER SYSTE

- Page 388 and 389:

9-14 ELECTRICAL SYSTEMSTARTER MOTOR

- Page 390 and 391:

9-16 ELECTRICAL SYSTEM• Align the

- Page 392 and 393:

9-18 ELECTRICAL SYSTEMGEAR POSITION

- Page 394 and 395:

9-20 ELECTRICAL SYSTEMIGNITION SYST

- Page 396 and 397:

9-22 ELECTRICAL SYSTEMOperationWhen

- Page 398 and 399:

9-24 ELECTRICAL SYSTEMStep 51) Insp

- Page 400 and 401:

9-26 ELECTRICAL SYSTEMNOTE:Use the

- Page 402 and 403:

9-28 ELECTRICAL SYSTEMIf the peak v

- Page 404 and 405:

9-30 ELECTRICAL SYSTEMREMOVAL AND D

- Page 406 and 407:

9-32 ELECTRICAL SYSTEMENGINE COOLAN

- Page 408 and 409:

9-34 ELECTRICAL SYSTEMSPEEDOMETERIf

- Page 410 and 411:

9-36 ELECTRICAL SYSTEMHEADLIGHT BEA

- Page 412 and 413:

9-38 ELECTRICAL SYSTEMIGNITION SWIT

- Page 414 and 415:

9-40 ELECTRICAL SYSTEMBATTERYSPECIF

- Page 416 and 417:

9-42 ELECTRICAL SYSTEMSERVICINGVisu

- Page 418 and 419:

10-2 SERVICING INFORMATIONTROUBLESH

- Page 420 and 421:

10-4 SERVICING INFORMATIONDTC No.C2

- Page 422 and 423:

10-6 SERVICING INFORMATIONENGINECom

- Page 424 and 425:

10-8 SERVICING INFORMATIONComplaint

- Page 426 and 427:

10-10 SERVICING INFORMATIONComplain

- Page 428 and 429:

10-12 SERVICING INFORMATIONRADIATOR

- Page 430 and 431:

10-14 SERVICING INFORMATIONBRAKESCo

- Page 432 and 433:

10-16 SERVICING INFORMATIONBATTERYC

- Page 434 and 435:

10-18 SERVICING INFORMATION26 N·m

- Page 436 and 437:

10-20 SERVICING INFORMATIONCABLE RO

- Page 438 and 439:

10-22 SERVICING INFORMATIONFUEL TAN

- Page 440 and 441:

10-24 SERVICING INFORMATIONFRONT BR

- Page 442 and 443:

10-26 SERVICING INFORMATIONFUEL TAN

- Page 444 and 445:

10-28 SERVICING INFORMATIONREAR FEN

- Page 446 and 447:

10-30 SERVICING INFORMATIONSIDE-STA

- Page 448 and 449:

10-32 SERVICING INFORMATIONREAR COM

- Page 450 and 451:

10-34 SERVICING INFORMATION09913-10

- Page 452 and 453:

10-36 SERVICING INFORMATION09940-40

- Page 454 and 455:

10-38 SERVICING INFORMATIONITEM N·

- Page 456 and 457:

10-40 SERVICING INFORMATIONTIGHTENI

- Page 458 and 459:

10-42 SERVICING INFORMATIONCYLINDER

- Page 460 and 461:

10-44 SERVICING INFORMATIONTHERMOST

- Page 462 and 463:

10-46 SERVICING INFORMATIONTHROTTLE

- Page 464 and 465:

10-48 SERVICING INFORMATIONTIRECold

- Page 466 and 467:

EMISSION CONTROL INFORMATION 11-1EM

- Page 468 and 469:

EMISSION CONTROL INFORMATION 11-3CR

- Page 470 and 471:

EMISSION CONTROL INFORMATION 11-5NO

- Page 472 and 473:

EMISSION CONTROL INFORMATION 11-7PA

- Page 474 and 475:

EMISSION CONTROL INFORMATION 11-9HE

- Page 476 and 477:

Prepared byOctober, 2005Part No. 99