- Page 1 and 2:

DELOREAN WORKSHOP MANUAL PJ. GRADY

- Page 3 and 4:

r r r • i r I r r I I Issued by:

- Page 5 and 6:

SERVICE ORGANISATION In order to pr

- Page 7 and 8:

i GENERAL SAFETY HINTS 1. Use the c

- Page 9 and 10:

• • r r r r r General Data CONT

- Page 11 and 12:

A:01:02 IGNITION SYSTEM (Contd.) Sp

- Page 13 and 14:

General Data A:02:01 ENGINE TUNING

- Page 15 and 16:

A:03:02 General Data DESCRIPTION TR

- Page 17 and 18:

A:03:04 General Data TORQUE FIGURES

- Page 19 and 20:

A — Overall Length B — Wheel Ba

- Page 21 and 22:

U 1 n PRE DELIVERY INSPECTION After

- Page 23 and 24:

I r r General Data LABEL IDENTIFICA

- Page 25 and 26:

f&T$ , W*$ fewt r jfi^T LABEL IDENT

- Page 27 and 28:

r r \r*l r

- Page 29 and 30:

IMPORTANT Fuel Tank B:01:01 REMOVIN

- Page 31 and 32:

Fuel Tank B:01:03 •

- Page 33 and 34:

Fig. 7 Number of Cylinders Bore Str

- Page 35 and 36:

TIGHTENING TORQUES-Figs. 3 and 4 No

- Page 37 and 38:

VALVE GUIDES Bore (mm) 8-8,022 (0.3

- Page 39 and 40:

r r r r r r r r r i r r CAMSHAFT Th

- Page 41 and 42:

REMOVING Disconnect battery. Remove

- Page 43 and 44:

Remove coolant hoses at engine Remo

- Page 45 and 46:

pm> fpg3\ ff&n, 0&t RETIGHTENING-TI

- Page 47 and 48:

Tl^ty r •'•*'j "*& Fig. 27 SECO

- Page 49 and 50:

• ^ * ? Remove the cylinder head

- Page 51 and 52:

that the camshaft top is fully with

- Page 53 and 54:

ROCKER SHAFTS DISMANTLING The oilwa

- Page 55 and 56:

- f CHANGING The engine need not be

- Page 57 and 58:

W&\ rrw\ EXAMPLE-Fig. 51 First meas

- Page 59 and 60:

Check that each small end is lying

- Page 61 and 62:

r Proceed in the same way for assem

- Page 63 and 64:

IflTtl "

- Page 65 and 66:

Remove the timing chains RH first t

- Page 67 and 68:

C:07:06 Engine Fig. 79 Refit the cr

- Page 69 and 70:

C:07:08 Engine ANGULAR TIGHTENING O

- Page 71 and 72:

Fig. 91 Lubricate the cylinder head

- Page 73 and 74:

Fig. 99 J 28860 Smear the crankshaf

- Page 75 and 76:

REMOVING Main Bearing Oil Seal—Fl

- Page 77 and 78:

- r REMOVING Drain engine oil Remov

- Page 79 and 80:

T^T) ryift] 7^1 I •'•'l p*^ Oil

- Page 81 and 82:

p^ is*l £T-- ? >'I I'-TVN) 1^1 •

- Page 83 and 84:

NOTE: The arm has LH and RH threade

- Page 85 and 86:

© "&•• ? o 9 (S> O C ,s '*•*

- Page 87 and 88:

Fuel Emission and Exhaust System CO

- Page 89 and 90:

V D:01:02 COMPONENT LOCATION Mixtur

- Page 91 and 92:

D:01:04 Fuel, Emission and Exhaust

- Page 93 and 94:

D:01:06 Fuel, Emission and Exhaust

- Page 95 and 96:

D:01:08 Fuel, Emission and Exhaust

- Page 97 and 98:

D:01:10 Fuel, Emission and Exhaust

- Page 99 and 100:

D:01:12 v. Fig. 12 High Control To

- Page 101 and 102:

D:01:14 Fuel Emission and Exhaust S

- Page 103 and 104:

D:01:16 Fuel, Emission and Exhaust

- Page 105 and 106:

D:02:02 TEST GAUGE CONNECTION VALVE

- Page 107 and 108:

&Wy Fuel, Emission and Exhaust Syst

- Page 109 and 110:

Fuel, Emission and Exhaust System D

- Page 111 and 112:

Fuel, Emission and Exhaust System D

- Page 113 and 114:

Fuel, Emission and Exhaust System D

- Page 115 and 116:

Fuel, Emission and Exhaust System D

- Page 117 and 118:

f^ r^ P" 1 Jr*!> Fig. 31 Fuel, Emis

- Page 119 and 120:

f^ H^I rm\ Pvf9| F/0. 34 Fuel, Emis

- Page 121 and 122:

7^:5 r^ K ''-i f*f!*l SPECIFICATION

- Page 123 and 124:

D:05:02 Fuel, Emission and Exhaust

- Page 125 and 126:

D:05:04 Fuel, Emission and Exhaust

- Page 127 and 128:

Fig. 42 A purge valve located insid

- Page 129 and 130:

Fuel Emission and Exhaust System D:

- Page 131 and 132:

V Fuel Emission and Exhaust System

- Page 133 and 134:

t— ^ REMOVING Fuel, Emission and

- Page 135 and 136:

P"^ I I'f'M ~^"H «wi p v H GENERAL

- Page 137 and 138:

Fmr-i P7^> P pfff rfa^ iwSS( J Fig.

- Page 139 and 140:

pn f^i r i tin*!) C*'"''-1 pfi^l n?

- Page 141 and 142:

^T^H, ^ rrr^ • T?*!l REMOVAL Clut

- Page 143 and 144: fF&H 0h BLEEDING SYSTEM 1. Top up c

- Page 145 and 146: Note: Do not use any cleaning fluid

- Page 147 and 148: CLUTCH PIPING The clutch pipe leadi

- Page 149 and 150: 5fW| V "f»TJ - fr"h GENERAL DESCRI

- Page 151 and 152: (TVS*) L I *W| M*J FFr^ff| GEAR RAT

- Page 153 and 154: f •:' 1 Manual Transmission F:04:

- Page 155 and 156: p"'4 /.•" iV-Ff r , ':'''^t TRANS

- Page 157 and 158: Manual Transmission OVERHAULING TRA

- Page 159 and 160: r r r r r r - r r r r r r r r r UNI

- Page 161 and 162: 1 r p*^ fr^) fiFrtr) 28. Clean the

- Page 163 and 164: r r r • - r r r r r Fig 26 Fig. 2

- Page 165 and 166: r i r r r r r r r i r I DIFFERENTIA

- Page 167 and 168: Manual Transmission F:06:11 5. Remo

- Page 169 and 170: CONTROLS DESCRIPTION AND OPERATION

- Page 171 and 172: - r r r r Automatic Transmission CO

- Page 173 and 174: G:01:02 Automatic Transmission achi

- Page 175 and 176: G:02:02 Automatic Transmission LOCA

- Page 177 and 178: DIAGNOSIS PROCEDURE 1. Road test th

- Page 179 and 180: FAULTS ENGINE STALLS UNEVEN IDLING

- Page 181 and 182: Automatic Transmission G:05:01 CHEC

- Page 183 and 184: Automatic Transmission G:05:03 / h

- Page 185 and 186: 5. Remove the solenoid mounting bol

- Page 187 and 188: G:06:04 Automatic Transmission 8. R

- Page 189 and 190: ' r v 1. Disconnect the negative ba

- Page 191 and 192: r i r r i r - • r j r r r i r r /

- Page 193: fT

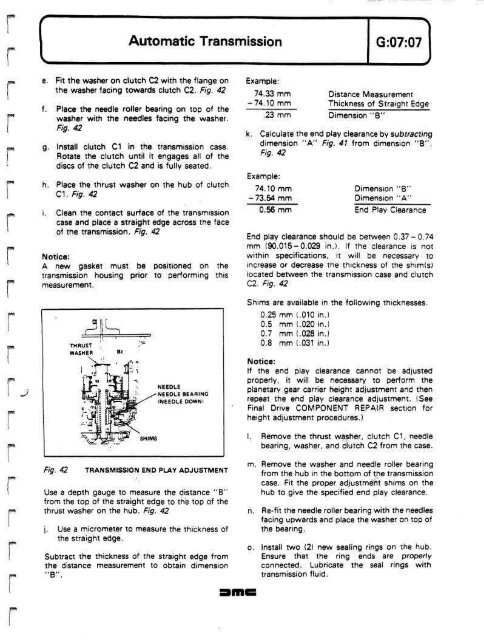

- Page 197 and 198: M pT^I TRANSMISSION UNIT DISASSEMBL

- Page 199 and 200: i f^) irm] 1 L /BTO BRAKE B-1 - Fig

- Page 201 and 202: i ' M p77iT| F0*t\ |f^'^T\ Fig. 50

- Page 203 and 204: r Fig. 57 C-1 PISTON SEALS Fig. 55

- Page 205 and 206: r r / V Fig. 60 Automatic Transmiss

- Page 207 and 208: v FINAL DRIVE DISASSEMBLY Automatic

- Page 209 and 210: r r Automatic Transmission G:09:03

- Page 211 and 212: ^ r \ Automatic Transmission G .09:

- Page 213 and 214: J Fig. 78 SIDE GEAR TOOL Reassembly

- Page 215 and 216: Automatic Transmission G:09:09 3. F

- Page 217 and 218: fj*«r |" CONTENTS ft**? j GENERAL

- Page 219 and 220: FW\ Location Lower column to univer

- Page 221 and 222: H:03:02 Steering 5. Position and se

- Page 223 and 224: REMOVAL - Fig. 7 1. Raise luggage c

- Page 225 and 226: REMOVAL 1. Remove rack and previous

- Page 227 and 228: Front Suspension J:01:01 GENERAL DE

- Page 229 and 230: REMOVAL 1. Raise car on hoist. 2. R

- Page 231 and 232: REMOVAL 1. Raise car on hoist. 2. R

- Page 233 and 234: J REMOVAL 1. Raise car on hoist. 2.

- Page 235 and 236: ~ J REMOVAL Front Suspension J:08:0

- Page 237 and 238: r r r r J REMOVAL 1 Raise car on ho

- Page 239 and 240: REMOVAL 1. Raise car on hoist, and

- Page 241 and 242: Contents GENERAL DESCRIPTION K.01.0

- Page 243 and 244: r r K:01:02 Rear Suspension

- Page 245 and 246:

;v?f?*) REMOVAL 1. Raise car on hoi

- Page 247 and 248:

REMOVAL Rear Suspension 1. Raise ca

- Page 249 and 250:

REMOVAL 1. Raise car on hoist. TRAI

- Page 251 and 252:

' 1. Check rear wheels for rim run

- Page 253 and 254:

r i r r r r r r I r r r r r I V* RE

- Page 255 and 256:

i-rw-] r r The vehicle is equipped

- Page 257 and 258:

T^M- w^ ••rrrr] J 1 ""?^ t ; -'

- Page 259 and 260:

Brakes, Wheels and Tyres 10. 11. Br

- Page 261 and 262:

installed. If the cylinder bore is

- Page 263 and 264:

I r REMOVAL 1. Remove brake disc pa

- Page 265 and 266:

jpffi pTI^ #6§ n*wi REMOVAL-Fig. 9

- Page 267 and 268:

BRAKE MASTER CYLINDER/FLUID RESERVO

- Page 269 and 270:

Automatic transmission only, Instal

- Page 271 and 272:

r r r r r r i r r r Brakes, Wheels

- Page 273 and 274:

1.1^-1 pwr^i jfrn^t ?TW$ r |!$P*I W

- Page 275 and 276:

'^WJ) p*sq pfl*V I The ignition sys

- Page 277 and 278:

J Electrical System and Instruments

- Page 279 and 280:

REMOVING - Fig. 7 DISCONNECT BATTER

- Page 281 and 282:

•jTv^ -ft'MWl rp9r\ REMOVING THE

- Page 283 and 284:

I r r r r r r r r r r r r r r r r r

- Page 285 and 286:

REMOVING - Fig. 17 1. Disconnect Ba

- Page 287 and 288:

REMOVING THE DIODE CARRIER - Fig. 1

- Page 289 and 290:

PF*1 f$&8) H*pi} T^JW) f^M MBQ) 1.

- Page 291 and 292:

M:05:02 Electrical System and Instr

- Page 293 and 294:

M :05:04 Electrical System and Inst

- Page 295 and 296:

M:06:02 Electrical System and Instr

- Page 297 and 298:

State-of-Charge (Example) A complet

- Page 299 and 300:

M:06:06 Electrical System and Instr

- Page 301 and 302:

X23C83U43 :C3H8C93!L153 JC4D1L10X16

- Page 303 and 304:

HORNS - Fig. 32 Twin high and low t

- Page 305 and 306:

M:09:02 Electrical System and Instr

- Page 307 and 308:

i F^I f Electrical System and Instr

- Page 309 and 310:

HEAD LAMP UNIT REMOVING - REFITTING

- Page 311 and 312:

Electrical System and Instruments J

- Page 313 and 314:

J Electrical System and Instruments

- Page 315 and 316:

*TO| fW^ SIDE/HEADLAMP SWITCH REMOV

- Page 317 and 318:

PT5 |VfW) pr^ rfTWi Electrical Syst

- Page 319 and 320:

pwj fW\ nm?i ffWKTi F^*i ITl*fl) ->

- Page 321 and 322:

r Electrical System and Instruments

- Page 323 and 324:

r Electrical System and Instruments

- Page 325 and 326:

J Electrical System and Instruments

- Page 327 and 328:

j .f?

- Page 329 and 330:

ffiytxy . J jffS^ Electrical System

- Page 331 and 332:

P 1 "^ IW'I r J f— V Electrical S

- Page 333 and 334:

|HW\ ^•r^n r^*i ^ Electrical Syst

- Page 335 and 336:

j •"fW'-wl . p^£\ I J Electrical

- Page 337 and 338:

j 1 :^' 1 ;! [fP*fl" "•y&i J Elec

- Page 339 and 340:

P'fTTB! '•5*TT) Electrical System

- Page 341 and 342:

i"^5r^ |WW| Electrical pw| L I \ I

- Page 343 and 344:

•wi »-;,^) J Electrical System a

- Page 345 and 346:

Pf*5j f^\ ,^wv 1 J fWW( JIM) p*B^ E

- Page 347 and 348:

p^?i jlfaj \vvtfl ffWrft J Electric

- Page 349 and 350:

I > P Heating and Air Conditioning

- Page 351 and 352:

The layout of the heater/air condit

- Page 353 and 354:

The temperature control should be t

- Page 355 and 356:

N:01:06 Heating and Air Conditionin

- Page 357 and 358:

N:01:08 Heating and Air Conditionin

- Page 359 and 360:

v Heating and Air Conditioning SPEC

- Page 361 and 362:

Heating and Air Conditioning N:02:0

- Page 363 and 364:

N .03:02 Heating and Air Conditioni

- Page 365 and 366:

v Heating and Air Conditioning Air

- Page 367 and 368:

J Heating and Air Conditioning N:05

- Page 369 and 370:

N:06:02 Heating and Air Conditionin

- Page 371 and 372:

J REMOVING HEATER/AIR CONDITIONING

- Page 373 and 374:

u a n ALL DIMENSIONS REFER TO WRENC

- Page 375 and 376:

Heating and Air Conditioning IM:08:

- Page 377 and 378:

J Heating and Air Conditioning N:08

- Page 379 and 380:

J Heating and Air Conditioning N .0

- Page 381 and 382:

Heating and Air Conditioning ;3^\»

- Page 383 and 384:

J INSTALLING COMPRESSOR Heating and

- Page 385 and 386:

J 1 2 3 4 i 5 i 1 ! ! 1 ! ! I ; i i

- Page 387 and 388:

J Heating and Air Conditioning N:08

- Page 389 and 390:

J Heating and Air Conditioning 3. D

- Page 391 and 392:

Heating and Air Conditioning N .08:

- Page 393 and 394:

NOT ENOUGH COOLING Move temperature

- Page 395 and 396:

N:09:04 Heating and Air Conditionin

- Page 397 and 398:

J Heating and Air Conditioning N:10

- Page 399 and 400:

The preceding Trouble Shooting Char

- Page 401 and 402:

Heating and Air Conditioning N:10:0

- Page 403 and 404:

J Heating and Air Conditioning N:10

- Page 405 and 406:

Heating and Air Conditioning Step 6

- Page 407 and 408:

JTffi^ J Heating and Air Conditioni

- Page 409 and 410:

f: :' ! .-^.*VJ ^ J Heating and Air

- Page 411 and 412:

a^i Fnff&J Ff^\ J CONTENTS GLASS RE

- Page 413 and 414:

STANDARD SECTIONAL REPAIR MOULDINGS

- Page 415 and 416:

(3) When completely cured, drill a

- Page 417 and 418:

FRONT FENDER, LEFT OR RIGHT - Rg. 1

- Page 419 and 420:

4. Install four screws securing rea

- Page 421 and 422:

2. Before fitting replacement, chec

- Page 423 and 424:

3. Mark angular position of torsion

- Page 425 and 426:

3. Remove handle and disconnect rel

- Page 427 and 428:

9. Move the interior locking contro

- Page 429 and 430:

3. Remove nut securing cable housin

- Page 431 and 432:

REAR WINDOW SUNSHADE LOUVRE Removal

- Page 433 and 434:

13. Position and secure front grill

- Page 437:

POWER WINDOW REGULATOR ASSEMBLY Rem

- Page 440 and 441:

" FIXED DOOR GLASS If replacement f

- Page 442 and 443:

j CONSOLE - Fig. 14 Removal 1. Disc

- Page 444 and 445:

J 6. Install either the left door p

- Page 446 and 447:

l» J CONTENTS GENERAL DESCRIPTION

- Page 448 and 449:

L ^ Chassis R:02:01 DIMENSIONS )

- Page 450 and 451:

A B C D E F G H 1 J K L M N 0 P 255

- Page 452 and 453:

• • ' ~ T »