Process Unit 73 LF - Knick

Process Unit 73 LF - Knick

Process Unit 73 LF - Knick

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Process</strong> <strong>Unit</strong> <strong>73</strong> <strong>LF</strong><br />

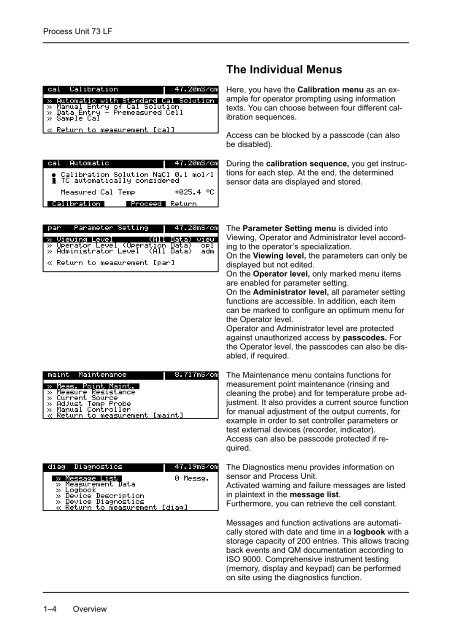

The Individual Menus<br />

Here, you have the Calibration menu as an example<br />

for operator prompting using information<br />

texts. You can choose between four different calibration<br />

sequences.<br />

Access can be blocked by a passcode (can also<br />

be disabled).<br />

During the calibration sequence, you get instructions<br />

for each step. At the end, the determined<br />

sensor data are displayed and stored.<br />

The Parameter Setting menu is divided into<br />

Viewing, Operator and Administrator level according<br />

to the operator’s specialization.<br />

On the Viewing level, the parameters can only be<br />

displayed but not edited.<br />

On the Operator level, only marked menu items<br />

are enabled for parameter setting.<br />

On the Administrator level, all parameter setting<br />

functions are accessible. In addition, each item<br />

can be marked to configure an optimum menu for<br />

the Operator level.<br />

Operator and Administrator level are protected<br />

against unauthorized access by passcodes. For<br />

the Operator level, the passcodes can also be disabled,<br />

if required.<br />

The Maintenance menu contains functions for<br />

measurement point maintenance (rinsing and<br />

cleaning the probe) and for temperature probe adjustment.<br />

It also provides a current source function<br />

for manual adjustment of the output currents, for<br />

example in order to set controller parameters or<br />

test external devices (recorder, indicator).<br />

Access can also be passcode protected if required.<br />

The Diagnostics menu provides information on<br />

sensor and <strong>Process</strong> <strong>Unit</strong>.<br />

Activated warning and failure messages are listed<br />

in plaintext in the message list.<br />

Furthermore, you can retrieve the cell constant.<br />

Messages and function activations are automatically<br />

stored with date and time in a logbook with a<br />

storage capacity of 200 entries. This allows tracing<br />

back events and QM documentation according to<br />

ISO 9000. Comprehensive instrument testing<br />

(memory, display and keypad) can be performed<br />

on site using the diagnostics function.<br />

1–4 Overview