Process Unit 73 LF - Knick

Process Unit 73 LF - Knick

Process Unit 73 LF - Knick

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Process</strong> <strong>Unit</strong> <strong>73</strong> <strong>LF</strong><br />

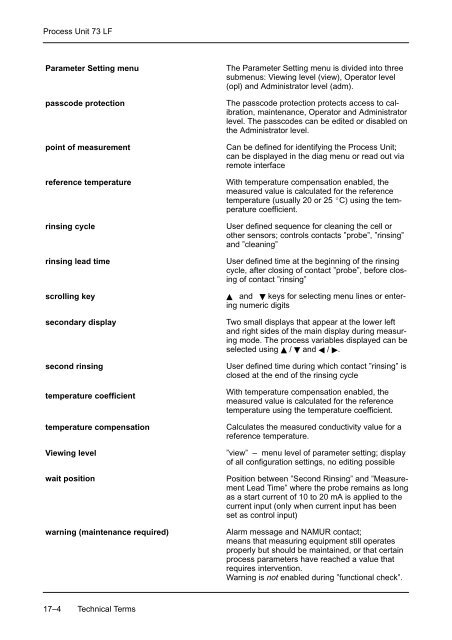

Parameter Setting menu<br />

passcode protection<br />

point of measurement<br />

reference temperature<br />

rinsing cycle<br />

rinsing lead time<br />

scrolling key<br />

secondary display<br />

second rinsing<br />

temperature coefficient<br />

temperature compensation<br />

Viewing level<br />

wait position<br />

warning (maintenance required)<br />

The Parameter Setting menu is divided into three<br />

submenus: Viewing level (view), Operator level<br />

(opl) and Administrator level (adm).<br />

The passcode protection protects access to calibration,<br />

maintenance, Operator and Administrator<br />

level. The passcodes can be edited or disabled on<br />

the Administrator level.<br />

Can be defined for identifying the <strong>Process</strong> <strong>Unit</strong>;<br />

can be displayed in the diag menu or read out via<br />

remote interface<br />

With temperature compensation enabled, the<br />

measured value is calculated for the reference<br />

temperature (usually 20 or 25 C) using the temperature<br />

coefficient.<br />

User defined sequence for cleaning the cell or<br />

other sensors; controls contacts ”probe”, ”rinsing”<br />

and ”cleaning”<br />

User defined time at the beginning of the rinsing<br />

cycle, after closing of contact ”probe”, before closing<br />

of contact ”rinsing”<br />

and keys for selecting menu lines or entering<br />

numeric digits<br />

Two small displays that appear at the lower left<br />

and right sides of the main display during measuring<br />

mode. The process variables displayed can be<br />

selected using / and / .<br />

User defined time during which contact ”rinsing” is<br />

closed at the end of the rinsing cycle<br />

With temperature compensation enabled, the<br />

measured value is calculated for the reference<br />

temperature using the temperature coefficient.<br />

Calculates the measured conductivity value for a<br />

reference temperature.<br />

”view” – menu level of parameter setting; display<br />

of all configuration settings, no editing possible<br />

Position between ”Second Rinsing” and ”Measurement<br />

Lead Time” where the probe remains as long<br />

as a start current of 10 to 20 mA is applied to the<br />

current input (only when current input has been<br />

set as control input)<br />

Alarm message and NAMUR contact;<br />

means that measuring equipment still operates<br />

properly but should be maintained, or that certain<br />

process parameters have reached a value that<br />

requires intervention.<br />

Warning is not enabled during ”functional check”.<br />

17–4 Technical Terms