Process Unit 73 LF - Knick

Process Unit 73 LF - Knick

Process Unit 73 LF - Knick

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

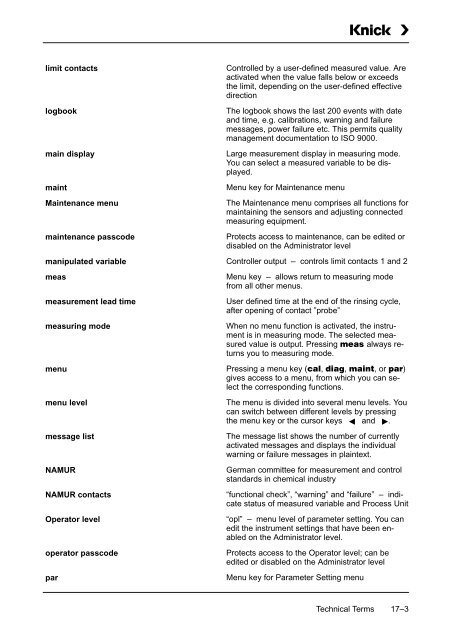

limit contacts<br />

logbook<br />

main display<br />

maint<br />

Maintenance menu<br />

maintenance passcode<br />

manipulated variable<br />

meas<br />

measurement lead time<br />

measuring mode<br />

menu<br />

menu level<br />

message list<br />

NAMUR<br />

NAMUR contacts<br />

Operator level<br />

operator passcode<br />

par<br />

Controlled by a user-defined measured value. Are<br />

activated when the value falls below or exceeds<br />

the limit, depending on the user-defined effective<br />

direction<br />

The logbook shows the last 200 events with date<br />

and time, e.g. calibrations, warning and failure<br />

messages, power failure etc. This permits quality<br />

management documentation to ISO 9000.<br />

Large measurement display in measuring mode.<br />

You can select a measured variable to be displayed.<br />

Menu key for Maintenance menu<br />

The Maintenance menu comprises all functions for<br />

maintaining the sensors and adjusting connected<br />

measuring equipment.<br />

Protects access to maintenance, can be edited or<br />

disabled on the Administrator level<br />

Controller output – controls limit contacts 1 and 2<br />

Menu key – allows return to measuring mode<br />

from all other menus.<br />

User defined time at the end of the rinsing cycle,<br />

after opening of contact ”probe”<br />

When no menu function is activated, the instrument<br />

is in measuring mode. The selected measured<br />

value is output. Pressing always returns<br />

you to measuring mode.<br />

Pressing a menu key (, , , or )<br />

gives access to a menu, from which you can select<br />

the corresponding functions.<br />

The menu is divided into several menu levels. You<br />

can switch between different levels by pressing<br />

the menu key or the cursor keys and .<br />

The message list shows the number of currently<br />

activated messages and displays the individual<br />

warning or failure messages in plaintext.<br />

German committee for measurement and control<br />

standards in chemical industry<br />

“functional check”, “warning” and “failure” – indicate<br />

status of measured variable and <strong>Process</strong> <strong>Unit</strong><br />

“opl” – menu level of parameter setting. You can<br />

edit the instrument settings that have been enabled<br />

on the Administrator level.<br />

Protects access to the Operator level; can be<br />

edited or disabled on the Administrator level<br />

Menu key for Parameter Setting menu<br />

Technical Terms 17–3