This section is available on request - MAN Diesel & Turbo

This section is available on request - MAN Diesel & Turbo

This section is available on request - MAN Diesel & Turbo

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>MAN</strong> B&W 17.05<br />

As the deflecti<strong>on</strong> shape for the H�type <str<strong>on</strong>g>is</str<strong>on</strong>g> equal<br />

for each cylinder the N th order H�type guide force<br />

moment for an N�cylinder engine with regular firing<br />

order <str<strong>on</strong>g>is</str<strong>on</strong>g>:<br />

N x M H(<strong>on</strong>e cylinder)<br />

For modelling purposes the size of the forces in<br />

the force couple <str<strong>on</strong>g>is</str<strong>on</strong>g>:<br />

Force = M H /L [kN]<br />

where L <str<strong>on</strong>g>is</str<strong>on</strong>g> the d<str<strong>on</strong>g>is</str<strong>on</strong>g>tance between crankshaft level<br />

and the middle positi<strong>on</strong> of the crosshead guide<br />

(i.e. the length of the c<strong>on</strong>necting rod.)<br />

As the interacti<strong>on</strong> between engine and hull <str<strong>on</strong>g>is</str<strong>on</strong>g> at<br />

the engine seating and the top bracing positi<strong>on</strong>s,<br />

th<str<strong>on</strong>g>is</str<strong>on</strong>g> force couple may alternatively be applied in<br />

those positi<strong>on</strong>s with a vertical d<str<strong>on</strong>g>is</str<strong>on</strong>g>tance of (L Z ).<br />

Then the force can be calculated as:<br />

Force Z = M H /L Z [kN]<br />

Any other vertical d<str<strong>on</strong>g>is</str<strong>on</strong>g>tance may be applied, so as<br />

to accomodate the actual hull (FEM) model.<br />

The force couple may be d<str<strong>on</strong>g>is</str<strong>on</strong>g>tributed at any<br />

number of points in the l<strong>on</strong>gitudinal directi<strong>on</strong>. A<br />

reas<strong>on</strong>able way of dividing the couple <str<strong>on</strong>g>is</str<strong>on</strong>g> by the<br />

number of top bracing and then applying the forces<br />

at those points.<br />

Force Z, <strong>on</strong>e point = Force Z, total /N top bracing, total [kN]<br />

X�type Guide Force Moment (M X )<br />

The X�type guide force moment <str<strong>on</strong>g>is</str<strong>on</strong>g> calculated<br />

based <strong>on</strong> the same force couple as described<br />

above. However as the deflecti<strong>on</strong> shape <str<strong>on</strong>g>is</str<strong>on</strong>g> tw<str<strong>on</strong>g>is</str<strong>on</strong>g>ting<br />

the engine each cylinder unit does not c<strong>on</strong>tribute<br />

with an equal amount. The centre units do not<br />

c<strong>on</strong>tribute very much whereas the units at each<br />

end c<strong>on</strong>tributes much.<br />

A so�called ‘Bi�moment’ can be calculated (Fig.<br />

17.05.01):<br />

‘Bi�moment’ = Σ [force�couple(cyl.X) x d<str<strong>on</strong>g>is</str<strong>on</strong>g>tX]<br />

in kNm 2<br />

Page of<br />

The X�type guide force moment <str<strong>on</strong>g>is</str<strong>on</strong>g> then defined<br />

as:<br />

M X = ‘Bi�Moment’/L kNm<br />

For modelling purpose the size of the four (4) forces<br />

can be calculated:<br />

Force = M X /L X [kN]<br />

where:<br />

L X <str<strong>on</strong>g>is</str<strong>on</strong>g> the horiz<strong>on</strong>tal length between ‘force points’<br />

Similar to the situati<strong>on</strong> for the H�type guide force<br />

moment, the forces may be applied in positi<strong>on</strong>s<br />

suitable for the FEM model of the hull. Thus the<br />

forces may be referred to another vertical level L Z<br />

above crankshaft centre line. These forces can be<br />

calculated as follows:<br />

Force = Z, <strong>on</strong>e point M _____ x L x<br />

L x L [kN]<br />

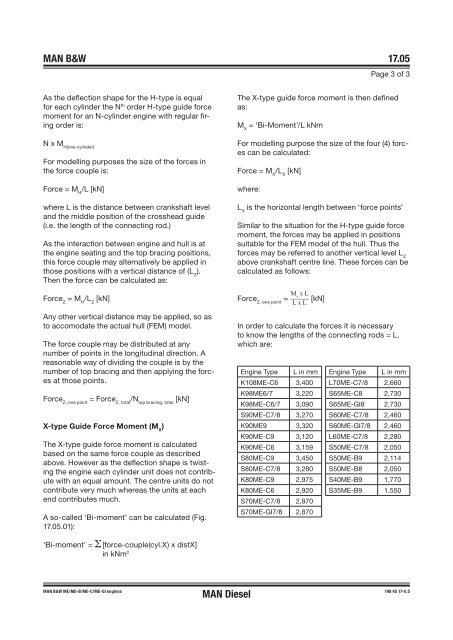

In order to calculate the forces it <str<strong>on</strong>g>is</str<strong>on</strong>g> necessary<br />

to know the lengths of the c<strong>on</strong>necting rods = L,<br />

which are:<br />

Engine Type L in mm<br />

K108ME�C6 ,400<br />

K98ME6/7 ,220<br />

K98ME�C6/7 ,090<br />

S90ME�C7/8 ,270<br />

K90ME9 , 20<br />

K90ME-C9 ,120<br />

K90ME�C6 ,159<br />

S80ME�C9 ,450<br />

S80ME�C7/8 ,280<br />

K80ME�C9 2,975<br />

K80ME�C6 2,920<br />

S70ME-C7/8 2,870<br />

S70ME�GI7/8 2,870<br />

Engine Type L in mm<br />

L70ME�C7/8 2,660<br />

S65ME�C8 2,7 0<br />

S65ME�GI8 2,7 0<br />

S60ME�C7/8 2,460<br />

S60ME�GI7/8 2,460<br />

L60ME�C7/8 2,280<br />

S50ME�C7/8 2,050<br />

S50ME-B9 2,114<br />

S50ME-B8 2,050<br />

S40ME-B9 1,770<br />

S 5ME-B9 1,550<br />

<strong>MAN</strong> B&W ME/ME-B/ME�C/ME�GI engines 198 45 17�0.5<br />

<strong>MAN</strong> <strong>Diesel</strong>