Carbon Nanotube Reinforced Composites: Metal and Ceramic ...

Carbon Nanotube Reinforced Composites: Metal and Ceramic ...

Carbon Nanotube Reinforced Composites: Metal and Ceramic ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

90j 3 Physical Properties of <strong>Carbon</strong> <strong>Nanotube</strong>–<strong>Metal</strong> Nanocomposites<br />

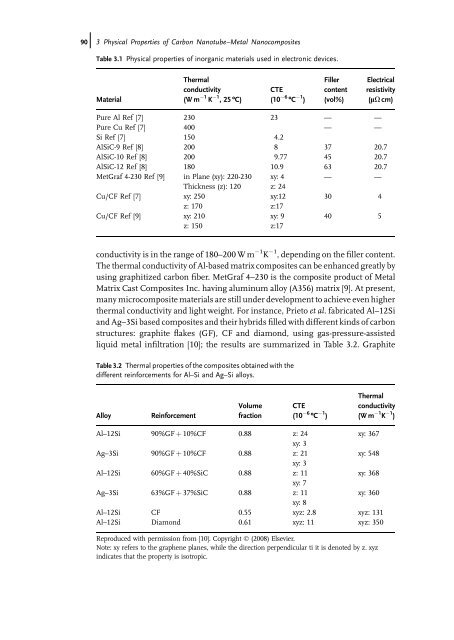

Table 3.1 Physical properties of inorganic materials used in electronic devices.<br />

Material<br />

Thermal<br />

conductivity<br />

(W m 1 K 1 , 25 ºC)<br />

CTE<br />

(10 6 ºC 1 )<br />

Filler<br />

content<br />

(vol%)<br />

Electrical<br />

resistivity<br />

(lO cm)<br />

Pure Al Ref [7] 230 23 — —<br />

Pure Cu Ref [7] 400 — —<br />

Si Ref [7] 150 4.2<br />

AlSiC-9 Ref [8] 200 8 37 20.7<br />

AlSiC-10 Ref [8] 200 9.77 45 20.7<br />

AlSiC-12 Ref [8] 180 10.9 63 20.7<br />

MetGraf 4-230 Ref [9] in Plane (xy): 220-230 xy: 4 — —<br />

Thickness (z): 120 z: 24<br />

Cu/CF Ref [7] xy: 250 xy:12 30 4<br />

z: 170 z:17<br />

Cu/CF Ref [9] xy: 210 xy: 9 40 5<br />

z: 150 z:17<br />

conductivity is in the range of 180–200 W m 1 K 1 , depending on the filler content.<br />

The thermal conductivity of Al-based matrix composites can be enhanced greatly by<br />

using graphitized carbon fiber. MetGraf 4–230 is the composite product of <strong>Metal</strong><br />

Matrix Cast <strong>Composites</strong> Inc. having aluminum alloy (A356) matrix [9]. At present,<br />

many microcomposite materials are still under development to achieve even higher<br />

thermal conductivity <strong>and</strong> light weight. For instance, Prieto et al. fabricated Al–12Si<br />

<strong>and</strong> Ag–3Si based composites <strong>and</strong> their hybrids filled with different kinds of carbon<br />

structures: graphite flakes (GF), CF <strong>and</strong> diamond, using gas-pressure-assisted<br />

liquid metal infiltration [10]; the results are summarized in Table 3.2. Graphite<br />

Table 3.2 Thermal properties of the composites obtained with the<br />

different reinforcements for Al–Si <strong>and</strong> Ag–Si alloys.<br />

Alloy Reinforcement<br />

Volume<br />

fraction<br />

CTE<br />

(10 6 ºC 1 )<br />

Thermal<br />

conductivity<br />

(W m 1 K 1 )<br />

Al–12Si 90%GF þ 10%CF 0.88 z: 24 xy: 367<br />

xy: 3<br />

Ag–3Si 90%GF þ 10%CF 0.88 z: 21 xy: 548<br />

xy: 3<br />

Al–12Si 60%GF þ 40%SiC 0.88 z: 11 xy: 368<br />

xy: 7<br />

Ag–3Si 63%GF þ 37%SiC 0.88 z: 11 xy: 360<br />

xy: 8<br />

Al–12Si CF 0.55 xyz: 2.8 xyz: 131<br />

Al–12Si Diamond 0.61 xyz: 11 xyz: 350<br />

Reproduced with permission from [10]. Copyright Ó (2008) Elsevier.<br />

Note: xy refers to the graphene planes, while the direction perpendicular ti it is denoted by z. xyz<br />

indicates that the property is isotropic.