Carbon Nanotube Reinforced Composites: Metal and Ceramic ...

Carbon Nanotube Reinforced Composites: Metal and Ceramic ...

Carbon Nanotube Reinforced Composites: Metal and Ceramic ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

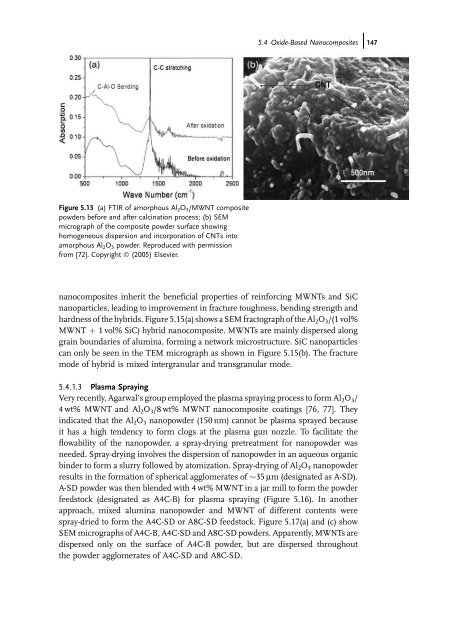

Figure 5.13 (a) FTIR of amorphous Al2O3/MWNT composite<br />

powders before <strong>and</strong> after calcination process; (b) SEM<br />

micrograph of the composite powder surface showing<br />

homogeneous dispersion <strong>and</strong> incorporation of CNTs into<br />

amorphous Al2O3 powder. Reproduced with permission<br />

from [72]. Copyright Ó (2005) Elsevier.<br />

5.4 Oxide-Based Nanocompositesj147<br />

nanocomposites inherit the beneficial properties of reinforcing MWNTs <strong>and</strong> SiC<br />

nanoparticles, leading to improvement in fracture toughness, bending strength <strong>and</strong><br />

hardness of the hybrids. Figure 5.15(a) shows a SEM fractograph of the Al2O3/(1 vol%<br />

MWNT þ 1 vol% SiC) hybrid nanocomposite. MWNTs are mainly dispersed along<br />

grain boundaries of alumina, forming a network microstructure. SiC nanoparticles<br />

can only be seen in the TEM micrograph as shown in Figure 5.15(b). The fracture<br />

mode of hybrid is mixed intergranular <strong>and</strong> transgranular mode.<br />

5.4.1.3 Plasma Spraying<br />

Very recently, Agarwal s group employed the plasma spraying process to form Al 2O 3/<br />

4 wt% MWNT <strong>and</strong> Al2O3/8 wt% MWNT nanocomposite coatings [76, 77]. They<br />

indicated that the Al2O3 nanopowder (150 nm) cannot be plasma sprayed because<br />

it has a high tendency to form clogs at the plasma gun nozzle. To facilitate the<br />

flowability of the nanopowder, a spray-drying pretreatment for nanopowder was<br />

needed. Spray-drying involves the dispersion of nanopowder in an aqueous organic<br />

binder to form a slurry followed by atomization. Spray-drying of Al2O3 nanopowder<br />

results in the formation of spherical agglomerates of 35 mm (designated as A-SD).<br />

A-SD powder was then blended with 4 wt% MWNT in a jar mill to form the powder<br />

feedstock (designated as A4C-B) for plasma spraying (Figure 5.16). In another<br />

approach, mixed alumina nanopowder <strong>and</strong> MWNT of different contents were<br />

spray-dried to form the A4C-SD or A8C-SD feedstock. Figure 5.17(a) <strong>and</strong> (c) show<br />

SEM micrographs of A4C-B, A4C-SD <strong>and</strong> A8C-SD powders. Apparently, MWNTs are<br />

dispersed only on the surface of A4C-B powder, but are dispersed throughout<br />

the powder agglomerates of A4C-SD <strong>and</strong> A8C-SD.