Carbon Nanotube Reinforced Composites: Metal and Ceramic ...

Carbon Nanotube Reinforced Composites: Metal and Ceramic ...

Carbon Nanotube Reinforced Composites: Metal and Ceramic ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

200j 7 Mechanical Properties of <strong>Carbon</strong> <strong>Nanotube</strong>–<strong>Ceramic</strong> Nanocomposites<br />

[Chap. 5, Ref. 76, Chap. 5, Ref. 77]. The fracture toughness of alumina (A-SD) coating<br />

is 3.22 0.22 MPa m 1/2 <strong>and</strong> increases to 3.862 0.16 MPa m 1/2 by adding 4 wt%<br />

MWNT (A4C-B) coating. The fracture toughness increases to 4.60 0.27 MPa m 1/2<br />

in the A4C-SD coating due to improved MWNTdispersion. It is further improved to<br />

5.04 0.58 MPa m 1/2 by adding 8 wt% MWNT (A8C-SD). The enhanced toughness<br />

of the alumina/MWNT nanocomposite coating is attributed to the CNT bridge<br />

formation, crack deflection <strong>and</strong> MWNT pull-out [24].<br />

7.3.2<br />

Silica Matrix<br />

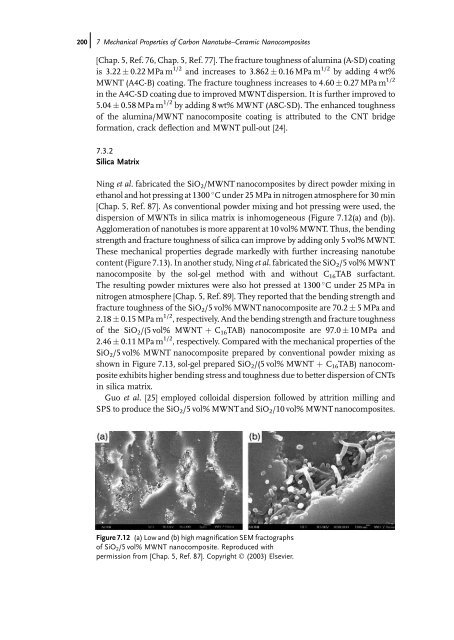

Ning et al. fabricated the SiO 2/MWNT nanocomposites by direct powder mixing in<br />

ethanol <strong>and</strong> hot pressing at 1300 C under 25 MPa in nitrogen atmosphere for 30 min<br />

[Chap. 5, Ref. 87]. As conventional powder mixing <strong>and</strong> hot pressing were used, the<br />

dispersion of MWNTs in silica matrix is inhomogeneous (Figure 7.12(a) <strong>and</strong> (b)).<br />

Agglomeration of nanotubes is more apparent at 10 vol% MWNT. Thus, the bending<br />

strength <strong>and</strong> fracture toughness of silica can improve by adding only 5 vol% MWNT.<br />

These mechanical properties degrade markedly with further increasing nanotube<br />

content (Figure 7.13). In another study, Ning et al. fabricated the SiO2/5 vol% MWNT<br />

nanocomposite by the sol-gel method with <strong>and</strong> without C 16TAB surfactant.<br />

The resulting powder mixtures were also hot pressed at 1300 C under 25 MPa in<br />

nitrogen atmosphere [Chap. 5, Ref. 89]. They reported that the bending strength <strong>and</strong><br />

fracture toughness of the SiO2/5 vol% MWNT nanocomposite are 70.2 5 MPa <strong>and</strong><br />

2.18 0.15 MPa m 1/2 , respectively. And the bending strength <strong>and</strong> fracture toughness<br />

of the SiO2/(5 vol% MWNT þ C16TAB) nanocomposite are 97.0 10 MPa <strong>and</strong><br />

2.46 0.11 MPa m 1/2 , respectively. Compared with the mechanical properties of the<br />

SiO2/5 vol% MWNT nanocomposite prepared by conventional powder mixing as<br />

shown in Figure 7.13, sol-gel prepared SiO 2/(5 vol% MWNT þ C 16TAB) nanocomposite<br />

exhibits higher bending stress <strong>and</strong> toughness due to better dispersion of CNTs<br />

in silica matrix.<br />

Guo et al. [25] employed colloidal dispersion followed by attrition milling <strong>and</strong><br />

SPS to produce the SiO2/5 vol% MWNT <strong>and</strong> SiO2/10 vol% MWNT nanocomposites.<br />

Figure 7.12 (a) Low <strong>and</strong> (b) high magnification SEM fractographs<br />

of SiO2/5 vol% MWNT nanocomposite. Reproduced with<br />

permission from [Chap. 5, Ref. 87]. Copyright Ó (2003) Elsevier.