Carbon Nanotube Reinforced Composites: Metal and Ceramic ...

Carbon Nanotube Reinforced Composites: Metal and Ceramic ...

Carbon Nanotube Reinforced Composites: Metal and Ceramic ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

116j 4 Mechanical Characteristics of <strong>Carbon</strong> <strong>Nanotube</strong>–<strong>Metal</strong> Nanocomposites<br />

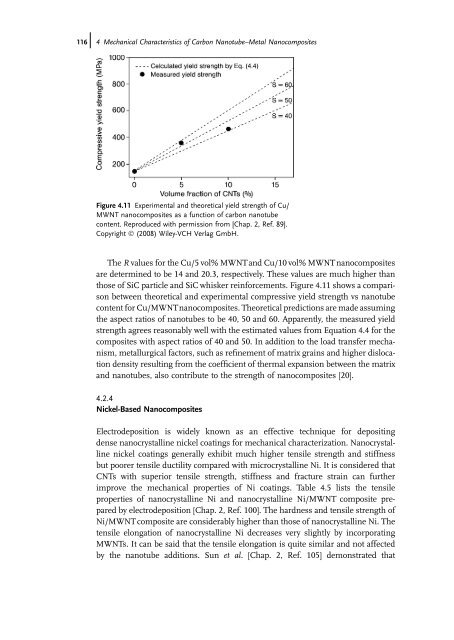

Figure 4.11 Experimental <strong>and</strong> theoretical yield strength of Cu/<br />

MWNT nanocomposites as a function of carbon nanotube<br />

content. Reproduced with permission from [Chap. 2, Ref. 89].<br />

Copyright Ó (2008) Wiley-VCH Verlag GmbH.<br />

The R values for the Cu/5 vol% MWNT<strong>and</strong> Cu/10 vol% MWNTnanocomposites<br />

are determined to be 14 <strong>and</strong> 20.3, respectively. These values are much higher than<br />

those of SiC particle <strong>and</strong> SiC whisker reinforcements. Figure 4.11 shows a comparison<br />

between theoretical <strong>and</strong> experimental compressive yield strength vs nanotube<br />

content for Cu/MWNTnanocomposites. Theoretical predictions are made assuming<br />

the aspect ratios of nanotubes to be 40, 50 <strong>and</strong> 60. Apparently, the measured yield<br />

strength agrees reasonably well with the estimated values from Equation 4.4 for the<br />

composites with aspect ratios of 40 <strong>and</strong> 50. In addition to the load transfer mechanism,<br />

metallurgical factors, such as refinement of matrix grains <strong>and</strong> higher dislocation<br />

density resulting from the coefficient of thermal expansion between the matrix<br />

<strong>and</strong> nanotubes, also contribute to the strength of nanocomposites [20].<br />

4.2.4<br />

Nickel-Based Nanocomposites<br />

Electrodeposition is widely known as an effective technique for depositing<br />

dense nanocrystalline nickel coatings for mechanical characterization. Nanocrystalline<br />

nickel coatings generally exhibit much higher tensile strength <strong>and</strong> stiffness<br />

but poorer tensile ductility compared with microcrystalline Ni. It is considered that<br />

CNTs with superior tensile strength, stiffness <strong>and</strong> fracture strain can further<br />

improve the mechanical properties of Ni coatings. Table 4.5 lists the tensile<br />

properties of nanocrystalline Ni <strong>and</strong> nanocrystalline Ni/MWNT composite prepared<br />

by electrodeposition [Chap. 2, Ref. 100]. The hardness <strong>and</strong> tensile strength of<br />

Ni/MWNT composite are considerably higher than those of nanocrystalline Ni. The<br />

tensile elongation of nanocrystalline Ni decreases very slightly by incorporating<br />

MWNTs. It can be said that the tensile elongation is quite similar <strong>and</strong> not affected<br />

by the nanotube additions. Sun et al. [Chap. 2, Ref. 105] demonstrated that