Carbon Nanotube Reinforced Composites: Metal and Ceramic ...

Carbon Nanotube Reinforced Composites: Metal and Ceramic ...

Carbon Nanotube Reinforced Composites: Metal and Ceramic ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

1.3.4<br />

Patent Processes<br />

<strong>Carbon</strong> nanotubes with unique, remarkable physical <strong>and</strong> mechanical characteristics<br />

are attractive materials for advanced engineering applications. Scientists from<br />

research laboratories worldwide have developed novel technical processes for the<br />

synthesis of nanotubes. Table 1.1 lists the patent processes approved by the United<br />

States Patent <strong>and</strong> Trademark Office recently for the synthesis of CNTs.<br />

US Patent 7329398 discloses a process for the production of CNTs or VGCFs<br />

by suspending metal catalyst nanoparticles in a gaseous phase [91]. Nanoparticles<br />

are prepared in the form of a colloidal solution in the presence or absence of a<br />

surfactant. They are then introduced in a gaseous phase into a heated reactor by<br />

spraying, injection or atomization together with a carrier <strong>and</strong>/or a carbon Source.<br />

Consequently, most of the problems faced by the conventional gas-phase synthetic<br />

processes can be overcome by this novel method.<br />

US Patent 7008605 discloses a non-catalytic process for producing MWNTs by<br />

using electric arc discharge technique [92]. The electric current creates an electric<br />

arc between the carbon anode <strong>and</strong> cathode under a protective inert gas atmosphere.<br />

The arc vaporizes carbon anode, depositing carbonaceous species on the carbon<br />

cathode. The anode <strong>and</strong> cathode are cooled continuously during discharge. When<br />

the electric current is terminated, the carbonaceous residue is removed from the<br />

cathode <strong>and</strong> is purified to yield CNTs.<br />

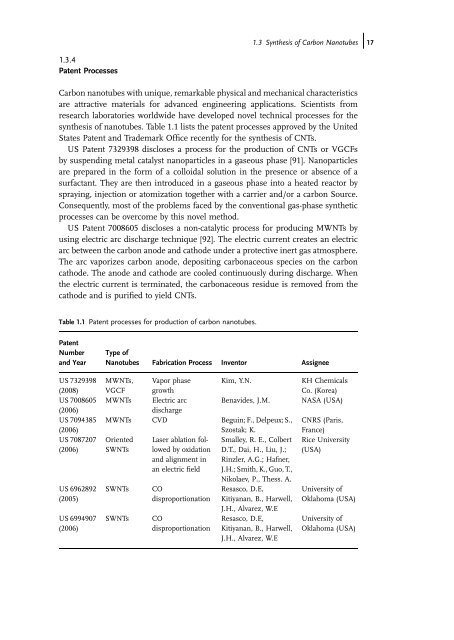

Table 1.1 Patent processes for production of carbon nanotubes.<br />

Patent<br />

Number<br />

<strong>and</strong> Year<br />

1.3 Synthesis of <strong>Carbon</strong> <strong>Nanotube</strong>sj17<br />

Type of<br />

<strong>Nanotube</strong>s Fabrication Process Inventor Assignee<br />

US 7329398 MWNTs, Vapor phase Kim, Y.N. KH Chemicals<br />

(2008) VGCF growth<br />

Co. (Korea)<br />

US 7008605 MWNTs Electric arc Benavides, J.M. NASA (USA)<br />

(2006)<br />

discharge<br />

US 7094385 MWNTs CVD Beguin; F., Delpeux; S., CNRS (Paris,<br />

(2006)<br />

Szostak; K.<br />

France)<br />

US 7087207 Oriented Laser ablation fol- Smalley, R. E., Colbert Rice University<br />

(2006) SWNTs lowed by oxidation D.T., Dai, H., Liu, J.; (USA)<br />

<strong>and</strong> alignment in Rinzler, A.G.; Hafner,<br />

an electric field J.H.; Smith, K., Guo, T.,<br />

Nikolaev, P., Thess. A.<br />

US 6962892 SWNTs CO<br />

Resasco, D.E,<br />

University of<br />

(2005)<br />

disproportionation Kitiyanan, B., Harwell,<br />

J.H., Alvarez, W.E<br />

Oklahoma (USA)<br />

US 6994907 SWNTs CO<br />

Resasco, D.E,<br />

University of<br />

(2006)<br />

disproportionation Kitiyanan, B., Harwell,<br />

J.H., Alvarez, W.E<br />

Oklahoma (USA)