Carbon Nanotube Reinforced Composites: Metal and Ceramic ...

Carbon Nanotube Reinforced Composites: Metal and Ceramic ...

Carbon Nanotube Reinforced Composites: Metal and Ceramic ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

190j 7 Mechanical Properties of <strong>Carbon</strong> <strong>Nanotube</strong>–<strong>Ceramic</strong> Nanocomposites<br />

These nanocomposites were prepared by hot pressing of synthesized in situ<br />

composite powders at 1500 C. The relative density (r.d.) values of hot-pressed<br />

Fe-Al2O3/8.5 vol% CNT <strong>and</strong> Fe-Al2O3/10 vol% CNT composites are 88.7 <strong>and</strong><br />

87.3%, respectively. Therefore, the alumina-CNT nanocomposites exhibit inferior<br />

mechanical properties due to their porous nature.<br />

More recently, Maensiri et al. investigated the mechanical properties of alumina/<br />

CNFnanocomposites reinforced with 1, 2.5 <strong>and</strong> 5 vol% CNF [19]. The nanocomposites<br />

were prepared by conventional powder mixing, ball-milling, followed by hot pressing<br />

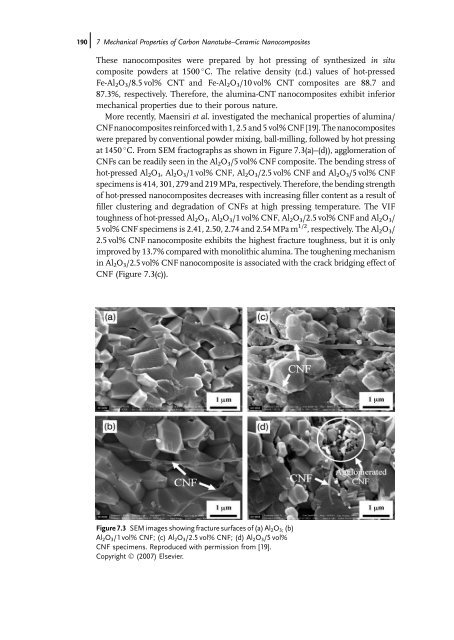

at 1450 C. From SEM fractographs as shown in Figure 7.3(a)–(d)), agglomeration of<br />

CNFs can be readily seen in the Al2O3/5 vol% CNF composite. The bending stress of<br />

hot-pressed Al2O3, Al2O3/1 vol% CNF, Al2O3/2.5 vol% CNF <strong>and</strong> Al2O3/5 vol% CNF<br />

specimens is 414, 301, 279 <strong>and</strong> 219 MPa, respectively. Therefore, the bending strength<br />

of hot-pressed nanocomposites decreases with increasing filler content as a result of<br />

filler clustering <strong>and</strong> degradation of CNFs at high pressing temperature. The VIF<br />

toughness of hot-pressed Al 2O 3,Al 2O 3/1 vol% CNF, Al 2O 3/2.5 vol% CNF <strong>and</strong> Al 2O 3/<br />

5 vol% CNF specimens is 2.41, 2.50, 2.74 <strong>and</strong> 2.54 MPa m 1/2 , respectively. The Al2O3/<br />

2.5 vol% CNF nanocomposite exhibits the highest fracture toughness, but it is only<br />

improved by 13.7% compared with monolithic alumina. The toughening mechanism<br />

in Al2O3/2.5 vol% CNF nanocomposite is associated with the crack bridging effect of<br />

CNF (Figure 7.3(c)).<br />

Figure 7.3 SEM images showing fracture surfaces of (a) Al2O3; (b)<br />

Al 2O 3/1 vol% CNF; (c) Al 2O 3/2.5 vol% CNF; (d) Al 2O 3/5 vol%<br />

CNF specimens. Reproduced with permission from [19].<br />

Copyright Ó (2007) Elsevier.