Carbon Nanotube Reinforced Composites: Metal and Ceramic ...

Carbon Nanotube Reinforced Composites: Metal and Ceramic ...

Carbon Nanotube Reinforced Composites: Metal and Ceramic ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

134j 5 <strong>Carbon</strong> <strong>Nanotube</strong>–<strong>Ceramic</strong> Nanocomposites<br />

temperatures. Superplastic deformation is of technological interest because it allows<br />

lower processing temperature <strong>and</strong> time, <strong>and</strong> enables near net shape forming of<br />

ceramic products. The ability to prevent premature failure of ceramics at high strain<br />

rates can have a large impact on the production processes.<br />

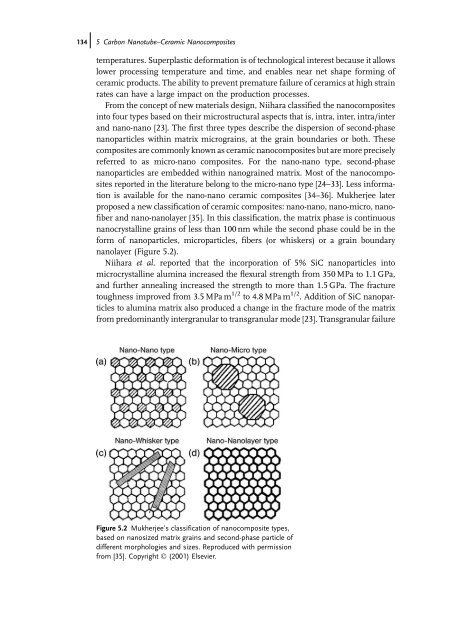

From the concept of new materials design, Niihara classified the nanocomposites<br />

into four types based on their microstructural aspects that is, intra, inter, intra/inter<br />

<strong>and</strong> nano-nano [23]. The first three types describe the dispersion of second-phase<br />

nanoparticles within matrix micrograins, at the grain boundaries or both. These<br />

composites are commonly known as ceramic nanocomposites but are more precisely<br />

referred to as micro-nano composites. For the nano-nano type, second-phase<br />

nanoparticles are embedded within nanograined matrix. Most of the nanocomposites<br />

reported in the literature belong to the micro-nano type [24–33]. Less information<br />

is available for the nano-nano ceramic composites [34–36]. Mukherjee later<br />

proposed a new classification of ceramic composites: nano-nano, nano-micro, nanofiber<br />

<strong>and</strong> nano-nanolayer [35]. In this classification, the matrix phase is continuous<br />

nanocrystalline grains of less than 100 nm while the second phase could be in the<br />

form of nanoparticles, microparticles, fibers (or whiskers) or a grain boundary<br />

nanolayer (Figure 5.2).<br />

Niihara et al. reported that the incorporation of 5% SiC nanoparticles into<br />

microcrystalline alumina increased the flexural strength from 350 MPa to 1.1 GPa,<br />

<strong>and</strong> further annealing increased the strength to more than 1.5 GPa. The fracture<br />

toughness improved from 3.5 MPa m 1/2 to 4.8 MPa m 1/2 . Addition of SiC nanoparticles<br />

to alumina matrix also produced a change in the fracture mode of the matrix<br />

from predominantly intergranular to transgranular mode [23]. Transgranular failure<br />

Figure 5.2 Mukherjee s classification of nanocomposite types,<br />

based on nanosized matrix grains <strong>and</strong> second-phase particle of<br />

different morphologies <strong>and</strong> sizes. Reproduced with permission<br />

from [35]. Copyright Ó (2001) Elsevier.