Carbon Nanotube Reinforced Composites: Metal and Ceramic ...

Carbon Nanotube Reinforced Composites: Metal and Ceramic ...

Carbon Nanotube Reinforced Composites: Metal and Ceramic ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

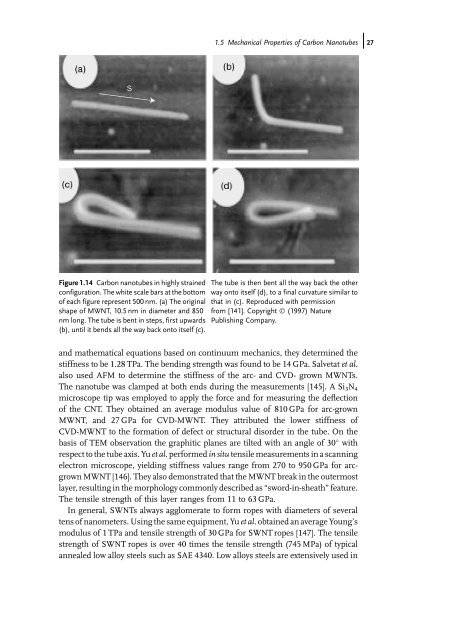

Figure 1.14 <strong>Carbon</strong> nanotubes in highly strained<br />

configuration. The white scale bars at the bottom<br />

of each figure represent 500 nm. (a) The original<br />

shape of MWNT, 10.5 nm in diameter <strong>and</strong> 850<br />

nm long. The tube is bent in steps, first upwards<br />

(b), until it bends all the way back onto itself (c).<br />

1.5 Mechanical Properties of <strong>Carbon</strong> <strong>Nanotube</strong>sj27<br />

The tube is then bent all the way back the other<br />

way onto itself (d), to a final curvature similar to<br />

that in (c). Reproduced with permission<br />

from [141]. Copyright Ó (1997) Nature<br />

Publishing Company.<br />

<strong>and</strong> mathematical equations based on continuum mechanics, they determined the<br />

stiffness to be 1.28 TPa. The bending strength was found to be 14 GPa. Salvetat et al.<br />

also used AFM to determine the stiffness of the arc- <strong>and</strong> CVD- grown MWNTs.<br />

The nanotube was clamped at both ends during the measurements [145]. A Si3N4<br />

microscope tip was employed to apply the force <strong>and</strong> for measuring the deflection<br />

of the CNT. They obtained an average modulus value of 810 GPa for arc-grown<br />

MWNT, <strong>and</strong> 27 GPa for CVD-MWNT. They attributed the lower stiffness of<br />

CVD-MWNT to the formation of defect or structural disorder in the tube. On the<br />

basis of TEM observation the graphitic planes are tilted with an angle of 30 with<br />

respect to the tube axis. Yu et al. performed in situ tensile measurements in a scanning<br />

electron microscope, yielding stiffness values range from 270 to 950 GPa for arcgrown<br />

MWNT [146]. They also demonstrated that the MWNT break in the outermost<br />

layer, resulting in the morphology commonly described as sword-in-sheath feature.<br />

The tensile strength of this layer ranges from 11 to 63 GPa.<br />

In general, SWNTs always agglomerate to form ropes with diameters of several<br />

tens of nanometers. Using the same equipment, Yu et al. obtained an average Young s<br />

modulus of 1 TPa <strong>and</strong> tensile strength of 30 GPa for SWNT ropes [147]. The tensile<br />

strength of SWNT ropes is over 40 times the tensile strength (745 MPa) of typical<br />

annealed low alloy steels such as SAE 4340. Low alloys steels are extensively used in