Carbon Nanotube Reinforced Composites: Metal and Ceramic ...

Carbon Nanotube Reinforced Composites: Metal and Ceramic ...

Carbon Nanotube Reinforced Composites: Metal and Ceramic ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

92j 3 Physical Properties of <strong>Carbon</strong> <strong>Nanotube</strong>–<strong>Metal</strong> Nanocomposites<br />

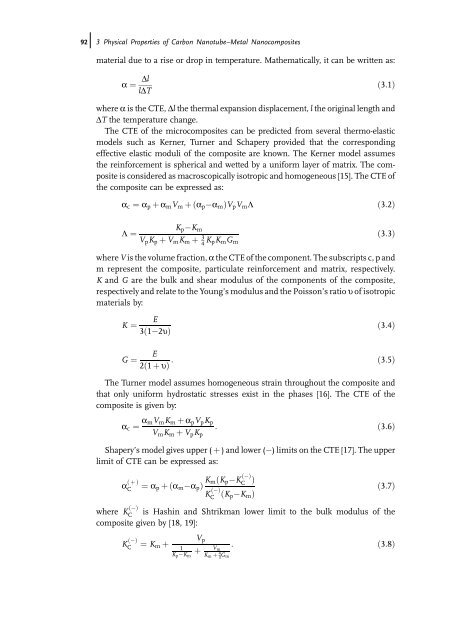

material due to a rise or drop in temperature. Mathematically, it can be written as:<br />

a ¼ Dl<br />

lDT<br />

ð3:1Þ<br />

where a is the CTE, Dl the thermal expansion displacement, l the original length <strong>and</strong><br />

DT the temperature change.<br />

The CTE of the microcomposites can be predicted from several thermo-elastic<br />

models such as Kerner, Turner <strong>and</strong> Schapery provided that the corresponding<br />

effective elastic moduli of the composite are known. The Kerner model assumes<br />

the reinforcement is spherical <strong>and</strong> wetted by a uniform layer of matrix. The composite<br />

is considered as macroscopically isotropic <strong>and</strong> homogeneous [15]. The CTE of<br />

the composite can be expressed as:<br />

ac ¼ ap þ amVm þðap amÞVpVmL ð3:2Þ<br />

L ¼<br />

Kp Km<br />

VpKp þ VmKm þ 3<br />

4 KpKmGm<br />

ð3:3Þ<br />

where V is the volume fraction, a the CTE of the component. The subscripts c, p <strong>and</strong><br />

m represent the composite, particulate reinforcement <strong>and</strong> matrix, respectively.<br />

K <strong>and</strong> G are the bulk <strong>and</strong> shear modulus of the components of the composite,<br />

respectively <strong>and</strong> relate to the Young s modulus <strong>and</strong> the Poisson s ratio u of isotropic<br />

materials by:<br />

K ¼<br />

G ¼<br />

E<br />

3ð1 2uÞ<br />

ð3:4Þ<br />

E<br />

: ð3:5Þ<br />

2ð1 þ uÞ<br />

The Turner model assumes homogeneous strain throughout the composite <strong>and</strong><br />

that only uniform hydrostatic stresses exist in the phases [16]. The CTE of the<br />

composite is given by:<br />

ac ¼ amVmKm þ apVpKp<br />

: ð3:6Þ<br />

VmKm þ VpKp<br />

Shapery s model gives upper ( þ ) <strong>and</strong> lower ( ) limits on the CTE [17]. The upper<br />

limit of CTE can be expressed as:<br />

ð Þ<br />

where KC a ðþÞ<br />

C ¼ ap þðam apÞ KmðKp<br />

ð Þ<br />

KC Þ<br />

ð Þ<br />

KC ðKp KmÞ<br />

ð3:7Þ<br />

is Hashin <strong>and</strong> Shtrikman lower limit to the bulk modulus of the<br />

composite given by [18, 19]:<br />

ð Þ<br />

KC ¼ Km<br />

Vp<br />

þ 1 Vm<br />

þ Kp Km Km þ 4 3Gm : ð3:8Þ